A recent Schrèder Group G.I.E. case study on street luminaires shows the advantages offered by printed board technologies. "Our challenge consisted of integrating LEDs into an existing luminaire housing, thus arranging the LED optics so that the light distribution is optimized relative to a luminaire with a fluorescent lamp," said LED project leader Steffen Holtz of R-Tech, Schrèder Group G.I.E.

A single HSMtec board fulfills three tasks:

- Light dispersion via flexible, yet self-supporting, printed board segments;

- Heat dissipation from the LEDs to the heat sinks by means of integrated copper profiles over the bending points to the heat sinks;

- Electrical connectivity to the LEDs over the bending points through integrated copper profiles over the bending points.

“For the first time we can dispense with a mechanical mounting for the printed board,” said Holtz. “For us, HSMtec is the basis for simplified, and thus more economical, production.

HSMtec's high degree of design freedom enables photometric flexibility and the use of innovative optics. Each LED can be arranged individually by arbitrarily setting the inclination angle of the PCB segments. The lighting designer can therefore influence the light characteristics of a luminaire and/or the illumination of objects.

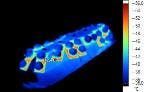

"Through the early involvement of Häusermann teams in our concept phase, it was possible to mutually coordinate and optimize the entire thermal design—from the printed board to the luminaire housing," explained Steffan Holtz. "Prototypes were rapidly and uncomplicatedly produced in different versions, accompanied by thermal analyses, which enabled us to use HSMtec technology optimally."

HSMtec technology, patented by Häusermann and qualified by independent test institutes, relies on standard FR-4 material, and can be obtained from prototypes up to full-production runs. The boards are produced by standard manufacturing processes, and HSMtec is qualified according to DIN EN 60068-2-14 and JEDEC A 101-A.

External copper parts (in the form of wires or profiles) are deposited directly onto the base copper by means of ultrasonic welding technology. This is carried out according to the customer's design specifications on those parts of the printed circuit board (PCB) where heat has to be dissipated, where high currents flow, or where the PCB has to be curved.

Based in Gars am Kamp, Austria, Häusermann GmbH specialises in the production of small and medium-sized batches of printed circuit boards with special reliability requirements.