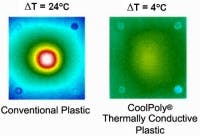

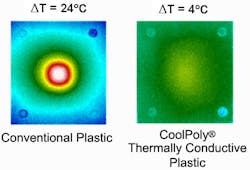

Date Announced: 10 May 2006 Performance Plastics Ltd has joined forces with US Company Cool Polymers® Inc. to represent their interests in the UK. The Rhode Island-based company who specialise in Thermally Conductive plastic materials, sold under the CoolPoly® brand name, were looking for a partner who would be able to offer the technical expertise required to market these patented materials, rather than a “one stop shop” which typifies many other UK distributors of plastics.The unique CoolPoly® materials typically offer a thermal conductivity from 1 to 20 W/m-K which is up to 100 times greater than normal thermoplastics, with some grades offering thermal conductivity of up to 100W/m-K. This means they fall in the same range as metals such as stainless steel, with a conductivity of 15W/m-K, and some aluminium alloys which range from 50-100W/m-K. The benefit of this is that not only does the plastic material allow heat to pass through it with ease; it also dissipates the heat much more evenly throughout a component, which prevents the build up of problematic hot spots.Photo caption: Infrared thermography of a 75mm square plate with a 5 watt heat source at the centre. Not only does the CoolPoly® material allow heat to pass through it, it distributes the heat more evenly, preventing the build up of a hot spot close to the heat source.CoolPoly® materials are based on a range of commodity and engineering thermoplastics polymers, such as PP, ABS, PC, PA, LCP, PPS, PEEK and TPE’s. Supplied in pellet form this enables them to be processed in a similar manner to unfilled materials, either by injection moulding or extrusion, without the need for special equipment. Thermally conductive plastics can reduce cycle time by up to 50%, and their inherently low coefficient of thermal expansion lowers shrink rates which allows dimensionally critical parts to be produced.The materials come in two ranges – the E series which are Electrically Conductive, and the D series which are electrically insulating. Both exhibit high levels of thermal conductivity.The E series has a range of electrical conductivity, measured as electrical resistivity between 0.1 and 10,000 ohm-cm, which is also appropriate for EMI and RFI shielding. The D series is electrically insulating whilst being thermally conductive. A unique combination for a melt processable material.The excellent thermal conductivity of CoolPoly®, aligned to its’ ease of processing, allows injection mouldable materials to be specified for applications traditionally made in metals or ceramics. The much greater design freedom associated with plastics, gives the designer an opportunity to manufacture parts with much more complex geometries, and to integrate multiple components into a single part, which is much lighter than their aluminium counterparts, and can offer electrical insulation if required without the loss of thermal conductivity.CoolPoly® materials are already being used in many areas where the build up of heat could is problematic, or would reduce the efficiency of a component, or where distortion caused by a hot spot is detrimental to the function of a part. Typical applications include functional heat sinks, heat exchangers, electrical bobbins, housings/reflectors for lighting (e.g. LEDs,) temperature sensors, connectors, enclosures for motors etc.

Contact

Eddie Thurloway Performance Plastics Ltd 3 Brock House, Grigg Lane, Brockenhurst, Hampshire, SO42 7RE Tel. 01590 622666 Mob. 07711 475258

E-mail:[email protected]