This article was published in the July/August 2013 issue of LEDs Magazine.

View the Table of Contents and download the PDF file of the complete July/August 2013 issue, or view the E-zine version in your browser.

+++++

The lighting market is evolving rapidly from traditional lighting sources to solid-state lighting (SSL) technology. The main drivers for this change are the need for greater energy efficiency due to rising energy costs and new legislation, both of which have global implications. With the market drive to mass adoption of SSL technology, lighting manufacturers must adapt to faster product development cycles that more closely match developments in LED technology. Developing fixtures that incorporate chip-on-board (COB) LED arrays is one avenue toward faster development, although that choice also comes with challenges in how to implement the electrical, thermal, and optical interfaces with the LED. This article provides background on COB technologies, summarizes the issues and challenges with COBs, and suggests a unique luminaire assembly and interconnect approach that simplifies luminaire design.

The world is facing a wide range of energy-related issues ranging from oft-debated global warming to diminishing fossil fuel supplies. Power generation limitations due to increasing demand or resulting from natural disasters in various regions result in brown-outs or even black-outs that directly affect quality of life for residents. These disruptions can extend to national productivity due to decreased manufacturing output at companies located in those regions. Political, economic, geographic, or logistical issues often limit adding power generation capacity to address the increased demand. Given this environment, countries around the world are fully engaged in trying to minimize their carbon footprints and decrease energy consumption, thereby lessening the strain on their energy infrastructure.

One major global effort is to decrease the energy load posed by the inefficient lighting systems in use today. Increasing global population and the resulting rise in demand for lighting can no longer be served by incandescent sources that accounted for 79% of light source sales volume in 2006. Collectively today, lighting energy consumption accounts for around 18% of the total global generated energy and cannot be allowed to continue. Simply switching to readily available, more energy-efficient light sources such as CFLs or LEDs can result in a 40% energy savings that would eliminate 630 million tonnes of CO2 and 1800 million barrels of oil. It would further cut down on the power-generating footprint, eliminating the need for almost six hundred 2-TW/yr power plants. Although it is neither feasible nor realistic to expect this change to happen overnight, phased regulations are in place around the world to ban the incandescent bulb. These are progressing and driving the changeover to incandescent alternatives — primarily turning to the LED moving forward.

HB LED evolution

Let's move on to LEDs, the evolution of the technology, and the challenges of SSL development. LEDs have gone through a significant transition since their inception that mimics the evolution of the single semiconductor transistor device morphing into the integrated circuit we know today. Early LEDs were low-power devices used for indicating purposes and are still in wide use today across many applications. In a manner similar to transistors, an indicator LED that cost $300 in the 1960s can now be purchased for less than $0.05 in a number of different package styles. As with transistors, LED technology transitioned from its original format as a low-power device to a high-power device in the late 1990s/early 2000s. While these earlier devices were considered high power, they were single-die packaged emitters with very limited light output and limited practical use.

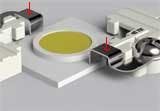

In an effort to increase light output, companies began placing multiple die in a lead-frame style package to increase light output and individually placed phosphor dots on each die to tune color. Around 2005, a new LED package was developed that eliminated the secondary LED package and placed the die directly on a metal-clad PCB substrate — collectively called chip-on-board or COB (Fig. 1). Rather than individual phosphor dots on each die, these COBs are characterized by a yellow-orange phosphor pool or slurry that covers all die and is typically centered on a white-colored substrate, giving these LEDs the nickname "fried-egg LEDs" due to their appearance.

These COB LEDs have undergone a proliferation over the past couple of years as all major LED manufacturers began offering COB products to the market. Unlike the smaller packaged LEDs that are considered point source emitters, COBs by their nature are wide area emitters with up to 204 0.25-mm2 die packed into a 12-mm-diameter area as seen in products offered by Nichia Corporation. In some instances, larger die are used in large arrays as seen in the Bridgelux products that place 64 1-mm2 die in a 35-mm-diameter area.

With light source areas this large, COBs are clearly positioned as broad angle emitters — their large source size becomes very difficult to effectively focus into a small beam angle. As a result, COBs are now found in applications requiring large amounts of light spread out across a large area as seen in high bay and street lighting. Still, optics such as reflectors can also enable the use of COB LEDs in applications including downlights and even reflector-based retrofit lamps.

Connecting packaged LEDs

Over the years, multiple connector companies developed a number of sockets for the high-power LEDs that came to market. In fact, the idea has spread that an LED is just another device to be connected to. Sockets such as the TE Type LS and Type NL2 (Fig. 2) devices were dedicated to a particular manufacturer's LED package and therefore had limited applicability beyond the specific targeted LED.

The emergence of COB LEDs posed different challenges to fixture manufacturers: how to provide power to these devices and then affix them to heat sinks in the lighting fixtures. The traditional method was to hand-solder the wires to the pads on the substrate (Fig. 3) and then secure these assemblies with screws to the heat sink — a process that was time consuming and subject to variability. As with the earlier discrete devices, this presented an ideal opportunity for socket solutions.

TE and other connector companies addressed this emergence of initial COB devices the same way earlier discrete LED packages were addressed: custom sockets. As other COBs started to enter the market, connector manufacturers realized that the status quo method of developing a socket for each would be prohibitively expensive and time consuming, resulting in never-ending efforts forever chasing the next new COB to enter the market.

With well over 50 different COB products commercially available around the world from multiple manufacturers, finding a single solution to address each would be a challenge to say the least. Aside from the fact that all were rectangular, all had two electrical contact pads, and most had circular light emitting surfaces, there were few other dimensional similarities. The challenge for connector companies was how to address these varied but similar COB LEDs with a minimum of engineering and tooling expenditure while providing a future-proof and flexible platform based product.

Scalable interconnects

One solution to the interconnect challenge is a flexible, scalable, platform-based socket. An analysis of available COBs yielded a crack in the shell of these "fried egg" LEDs. While not exactly identical, there are similarities between contact pad locations that, when combined with the rectangular nature of the devices and diagonal contact pad placement, form the basis for the platform solution. As a result, a holder product, referenced off the corners of the COB, could yield a virtually limitless array of use scenarios with the varied COBs available on the market as well as those to come in the future.

The substrate differences among COB LEDs from difference manufacturers, however, added yet another issue that needs to be tackled by socket/holder suppliers. While most of the early COBs incorporated aluminum substrates, further investigation of the commercially available COBs indicated a number of COBs that are based on ceramic substrates (typically aluminum nitride). While not a significant differentiator, these two substrate variants have physical features that differ enough to require special handling due to their different material properties.

The aluminum substrate COBs are rather robust and in some instances are mounted using machine screws. On the other hand, ceramic-based COBs create some frustration for fixture manufacturers since unlike aluminum-based substrates where they could simply secure the COBs with a screw to a heat sink, these ceramic substrates are far too brittle to secure with screws and thereby mandate some sort of secondary attachment to ensure suitable thermal performance. This attachment needs to be accomplished using thermal adhesives or by a mechanical holder that provides normal force to the heat sink or thermal pad, mechanical attachment, and electrical interconnection.

Holder devices that accommodate the COB nuances mentioned in the previous paragraphs are appearing on the market. An example of one such platform solution is the TE Scalable LED Socket connector that utilizes the corners of the COB as a reference. In this manner, the two datums formed by the sides of the COB can be used to positively locate the electrical contact on each of the COB's electrical pads.

Moreover, the diagonally opposed contact pads on most COBs can allow the luminaire industry to leverage the symmetry. The symmetry can enable use of the same socket assembly on both corners of the COB (Fig. 4). By doing this, SKU (stock keeping units) or model numbers are drastically reduced by eliminating the need for right and left versions of the socket, providing an advantage for socket makers, distributors, and SSL manufacturers.

Managing substrate height

The variability of COB thickness poses yet another design challenge for a socket product. COB substrates are available in a variety of materials and thicknesses that need to be accommodated. The thinner and more brittle ceramic packages can easily crack under pressure when used with flexible thermal interface pads and therefore consequentially use greases as thermal interface materials (TIMs) to optimize the thermal path from the LED substrate to the heat sink. On the other hand, the more durable aluminum substrates can use grease or flexible TIMs.

Any holder being considered by an SSL manufacturer needs to be evaluated relative to how it accommodates these varying stack heights posed by COB applications. One method is commercially available that utilizes a combination of optional thermal springs and housing ledges to accommodate both types of COBs. An example using an aluminum substrate COB is shown in Fig. 5. The red circle indicates how the housing is used to secure the COB against the heat sink.

When the same system is used with the thinner ceramic substrates as shown in Fig. 6, clearance needs to be provided to avoid exerting pressure on the ceramic substrate. The housing design naturally clears the thinner ceramic COB as indicated by the red circle. Since the electrical contact spring is inadequate to provide an appreciable normal force for thermal contact, a secondary thermal spring is incorporated and is seen in Fig. 7. A pair of these springs can exert just the right amount of force on a ceramic device to ensure optimal heat transfer when used with most commercially available thermal greases.

Simplifying manufacturing

While a two-piece socket design affords a significant level of scalability to accommodate a wide range of COBs, some fixture manufacturers prefer to only handle a single part. Additional levels of scalability can be incorporated into a two-piece design by the relatively simple addition of two arms oriented at 90° to each other. These arms essentially create a scalable, factory-assembled one-piece housing. A customized holder is then available to fit a specific manufacturer's COB LED (Fig. 8).

A scalable approach to the interconnect enables a more generic two-piece design or a customized one-piece design, and either can be used by the fixture manufacturer with very little cost difference between the two. Consider the option a stepping-stone approach. A lighting manufacturer can minimize the interconnect investment during prototyping by launching the fixture using a readily available two-piece holder solution. Once production ramp starts, the manufacturers can switch to a more manufacturing-friendly one-piece design.

Ideally, having a single holder to accommodate all COBs would be the perfect solution. Given the slight differences in pad locations between commercially available COB products and the different plating styles commonly used, that perfect solution is still elusive. Nonetheless, with a scalable holder solution, solderless interconnections to a broad range of COBs are possible with a very small number of socket SKUs that can accommodate a wide range of commercially available products.

COB corner holders are also quite adaptable. An additional benefit to the holders referencing off the corners of a COB is that the applicability of these holders can extend beyond COBs. By using the same corner holders used to provide power into a COB, large printed circuit boards containing massive arrays of LEDs can be powered in a similar fashion through pads located on the corners of the circuit board.

In conclusion, COB holders, in particular those that reference off the device corners, offer lighting fixture manufacturers a unique and flexible termination solution for their COB LED attachment and interconnect needs. By utilizing a holder designed from the start as a scalable platform, fixture manufacturers gain the flexibility to utilize a broad range of light source options. From a COB LED manufacturer's point of view, the availability of a common holder design provides a stable reference for manufacturers designing a new COB package since the use of pre-defined contact pad locations ensures the availability of an off-the-shelf holder solution when a new COB is released to the market.

The global march toward energy efficiency continues. LED lighting will play a major role and, as with all new technologies, efficiencies are increasing while costs are dropping. The need for cost-effective LED lighting is putting a renewed emphasis on cost and manufacturability, which is where both COB LEDs and the COB holders offer customers an ideal cost-effective solution that will accelerate LED adoption.