New UV-C LED sources are driving innovation to achieve size and cost reductions in instrument design for life sciences applications, writes HARI VENUGOPALAN, improving productivity and reliability without sacrificing performance.

Many laboratories in the life science fields rely on fast, accurate, and dependable measurements for their applications. This is especially true in high-performance liquid chromatography (HPLC) and DNA concentration and purity measurements, which rely on quantitative analysis through absorption spectroscopy. Leading instrument manufacturers for these applications are seeking alternative light sources, such as UV-C (ultraviolet LEDs in the C band in the range of 100-280 nm), as a means to satisfy new needs for their end users. UV-C LEDs can offer these manufacturers opportunities for miniaturization and lower cost solutions to differentiate their offerings and expand market penetration.

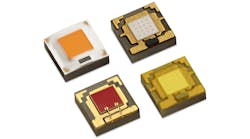

UV LEDs in other bands are already broadly used in some notable applications. For example, LEDs Magazine published a feature article earlier this year on UV-A (315-400 nm) LEDs used in curing applications. UV-C LED usage has been limited by the LED efficiency as was discussed in an article on a Strategies in Light presentation (http://bit.ly/1kXzh1e). But Crystal IS has made great progress with UV-C LEDs especially at the upper end of the band.

UV-C LEDs in the upper range are useful in a number of test-and-measurement-centric applications for life sciences. Laboratories are looking for smaller instruments that cost less than their bulky counterparts to drive productivity and lab performance. Emerging technologies are allowing miniaturization of instruments, which not only reduces costs but also maximizes lab real estate. The availability of low cost, small footprint LED-based instruments enables researchers to have instruments on their workbenches for routine measurements. At the same time, when full spectrum measurements are needed, researchers can access the more expensive, full spectrum UV-lamp-based instruments available at central locations in the lab. This reduces laboratory bottlenecks and improves productivity.

Until recently, instrument manufacturers have been hampered in their development by the aforementioned lower performance of commercially available UV-C LEDs. However, as higher-performance components become available, manufacturers can capitalize on the capabilities of LEDs to address these trends with new instrument models. Now let's discuss some applications in which UV-C LEDs are used today.

UV-C LEDs benefit fixed-wavelength detection in HPLC

HPLC is a separation technique in which a sample mixture is introduced into a column. The different compounds of the mixture pass through the column at varying rates due to differences in their partitioning behavior between the mobile phase and the stationary phase. Detection of these components is primarily analyzed by absorption spectroscopy using a UV spectrophotometer. HPLC is typically used for protein purification, routine process monitoring in pharmaceutical and beverage manufacturing, quality control, and biotech research.

Current HPLC detectors typically use deuterium lamps as their primary light source. HPLC manufacturers select deuterium lamps because of the high stability of light output through the duration of a measurement. High light-output stability of a UV light source in HPLC ensures detection of lower concentrations of compounds. A comparison of UV lamps done by Hamamatsu, a manufacturer of spectrometer components, indicates that compared with other UV lamps such as xenon flash or mercury, deuterium lamps have two orders-of-magnitude better stability.

LEDs deliver on stability requirements

Newly available high-performance UV LEDs rival the stability of high-end deuterium lamps with a peak-to-peak fluctuation of 0.005% or lower. UV-C LEDs offer similar sensitivity while reducing the overall instrument cost and size for fixed-wavelength detection. This allows manufacturers to help end users optimize their laboratory real estate with smaller units when they require a single or few fixed wavelengths. In addition, LEDs offer longer life and instantly turn on, ensuring that LED lifetime is not wasted in warm-up - unlike deuterium lamps. Furthermore, the emission from LEDs can be easily fiber coupled, which is an advantage in applications where the flow cell needs to be isolated. This opens the door for manufacturers to select UV-C LEDs as an alternate light source for fixed-wavelength detectors and build more cost-effective systems.

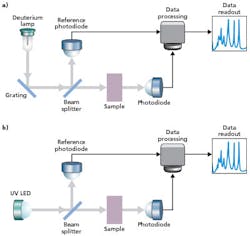

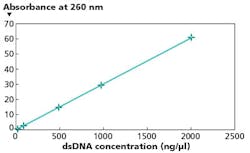

For fixed-wavelength HPLC systems, the largest difference in cost generally stems from the initial setup cost, as this includes both the light source and any ancillary equipment. An HPLC system using an LED detector would require a power supply, photodiodes, and a beam splitter. A typical total cost for an HPLC detector system with LEDs is approximately $750. In contrast, an HPLC system that uses a deuterium light source requires more costly equipment to build. The necessary power supply is much more expensive, and a housing is required to store the lamp. In addition, deuterium lamps are broad-spectrum sources, emitting light across many wavelengths in the UV range. This necessitates the use of expensive filters and monochromators for fixed-wavelength HPLC detection. As a result, a typical system cost is expected to be closer to $4,000. Fig. 1 shows a typical instrument design using a deuterium lamp (a) versus one incorporating a UV-C LED (b).

Reducing costs for DNA purity measurements

Moving to another example of UV-C LED usage, DNA concentration and purity measurements, which use absorption spectroscopy, are the first step in the analyses for many life science applications. The extraction of DNA ensures the integrity of biological research and impacts fields such as biotechnology, forensics, genomic research, and pharmaceuticals. This includes the detection of genetic disorders, production of DNA fingerprints, and creation of genetically engineered organisms that can produce beneficial products such as insulin.

The drive to increase productivity and reduce costs in these applications centers on the speed and accuracy of measurement. DNA and protein have absorption peaks at 260 nm and 280 nm, and the absorbances at these wavelengths determine the concentration of DNA and protein, respectively, while the ratio of the absorbances determines the purity of the DNA sample. Spectrometers for DNA concentration and purity measurements rely on xenon flash lamps, which offer instant on/off for quick evaluation with high linearity of measurement over a wide concentration range.

Although broad-spectrum UV lamps such as xenon flash lamps generate ample light across multiple wavelengths (a significant fraction of the optical energy is in the visible spectrum), only light at a particular wavelength is useful for any single parameter measurement. Since DNA purity is determined by absorbance measurements taken specifically at 260 nm and 280 nm, additional elements such as filters and mirrors must be used to filter out unwanted wavelengths before light from the broad spectrum lamp hits the sample. Xenon flash lamps also require high voltages and increased shielding of electronics during lamp ignition. These expensive electronics coupled with additional optical components quickly add to the overall cost of the instrument.

LED and UV lamp spectra

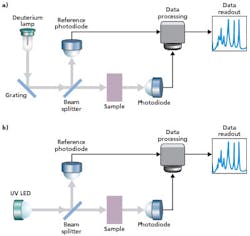

Within the narrow range of wavelengths defined by the absorbance measurement for either DNA or protein, UV-C LEDs can match the measurement performance of xenon flash lamps. Fig. 2 compares the spectral irradiance of a 1-mW, 260-nm UV-C LED with a 15W xenon flash lamp.

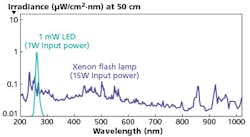

The high light output of the LED allows for a lower detection limit of 0.5 ng/μl for concentration of double-stranded DNA (dsDNA), and the excellent spectral quality of the LED leads to linearity of measurement over three orders-of-magnitude of concentration from 0.5-2000 ng/μl (Fig. 3).

The performance and monochromaticity of LEDs results in a simpler design than the xenon flash lamp instrument - one that requires fewer optical elements and therefore lowers system cost. Additionally, power sources for UV-C LEDs are less complex and less costly. The reduction in component costs allows for a more cost-effective instrument to be manufactured without sacrificing performance for DNA purity measurements. The table compares typical optical component costs for a fixed-wavelength detector for measurements at 260 nm and 280 nm. The xenon flash lamp system assumes two filters to achieve those wavelengths while the UV-C LED system uses two LEDs - one at each wavelength.

A comparison of systems for DNA purity measurements. | ||

Xenon flash lamp system | UV-C LED system | |

Light source | $600 | $600 |

Power supply and trigger socket* | $1000 | $50 |

Excitation filter for 260 nm | $350 | $0 |

Excitation filter for 280 nm | $350 | $0 |

Silicon photodiodes (UV enhanced) | $100 | $100 |

Total | $2400 | $750 |

*Systems using xenon flash lamps require a trigger socket in addition to the power supply. This is not necessary for LED-based systems. | ||

System efficiency for LED implementations

Component costs provide a significant difference in initial system cost. However, the system efficiency is also a factor that contributes to the overall costs. In the system examples given here, the power consumption for the UV-C LED system is approximately 2W (1W per LED). A typical xenon flash lamp will operate at an average power that ranges between 2W and 60W. Indeed, the UV-C LED system offers a more efficient light source for fixed- wavelength measurements. As a significant amount of light output from the xenon flash lamp is filtered out in the unwanted wavelengths, the LED provides more power output at the desired wavelength as seen earlier on in Fig. 2.

As demonstrated here, systems using UV-C LEDs can match and may even sometimes exceed the performance of systems using UV lamps, while at the same time delivering higher efficiency and reduced costs for fixed-wavelength applications. The comparable performance allows the instrument designer to capitalize on the other benefits of UV-C LEDs, such as cost and size, without sacrificing product performance for these complex tasks. UV-C LEDs enable longer instrument life, higher reliability, and increased productivity while reducing overall costs for the end user. These new devices are driving innovations in instrument design for the life sciences to address key market trends around productivity, cost reduction, and miniaturization.

HARI VENUGOPALAN is director of global product management at Crystal IS.