Implementing LED flash in camera phones

Since camera phones are now being used as “serious” digital cameras, users are expecting to be able to take quality pictures in low-light-level conditions . This is where adding a small illumination source that won’t rapidly drain the cell phone’s battery comes into play.

Why choose LED flash for camera phonesToday, there are two available choices for digital camera photoflashes: the xenon flash tube (widely used in all forms of photography) and white LEDs. Each offers unique features and benefits, and possesses advantages in different digital camera market segments. The xenon flash is practically universally used for both film cameras and stand-alone digital still cameras (DSCs) because of its high brightness. White LED illumination is the choice for most camera phones.Basically, a xenon flash is a cylindrical glass envelope filled with xenon gas. Multi-kilovolts are needed to reach the gas breakdown potential, before generating a high current surge through the xenon gas, producing intense light.

On the other hand LEDs are current-driven devices in which the light output depends directly on the forward current passing through them. LEDs can be strobed faster than any other light source, including xenon, and have very short rise times, in the range of 10 to 100 ns.The white light is produced by the combination of the blue photons emitted from forward biasing an InGaN chip and yellow light, a result of phosphor excitation by blue photons. The resulting lighting quality is comparable to that of cool white fluorescent lamps, with a color rendering index near 85.

The maximum light output from a LED is in most cases limited by the maximum average forward current it can handle, which is determined mainly by the combination of the power dissipation capability of the LED chip/package combination and the performance of any heat sink to which it is attached. In flash applications the LED may be operated from a pulsed current with a very short duty cycle. This allows the current and hence the light output to be increased significantly during the actual pulses, while still keeping the LED’s average current level and power dissipation within its safe ratings.

In digital still cameras, a high brightness flash is needed, and the size and power consumption are less significant because a digital still camera can provide more room for the required drive circuit and its battery capacity is devoted entirely to operating the camera and flash. Undoubtedly a xenon flash is the best choice for a digital still camera.

On the other hand, an LED flash offers lower power consumption with drive circuitry that takes up very little room. Additionally, there is no significant electromagnetic interference (EMI) generated from driving an LED flash.

Selecting LEDs for camera phone flash applications

There are a number of different LED assemblies that manufacturers specify for camera flash operation and there are no packaging or electrical standards in the flash LED market. Designers who are not familiar with LED flash design might find themselves having difficulties in selecting an appropriate LED assembly and may discover later problems if they design-in an unsuitable assembly.

There are a number of criteria that should be considered when designing an LED flash into a camera phone. They are:

* Optical characteristics

* Electrical design simplicity and flexibility

* Pulsing capability

* Ability to effectively cascade modules for higher light output

* Thermal considerations

* Manufacturing and assembly considerations: particularly the compatibility of an LED module with manufacturing processes.

Optical characteristics

Most of the digital camera modules currently being used in camera phones have a 50- to 60-degree field of view and need a minimum of 3 to 5 lux to capture a good picture. Hence, a camera flash with a 50- to 80-degree illumination angle is optimal. An illumination angle wider than 80 degrees will cause a portion of light to fall outside the camera’s coverage, under-utilizing the light output from the LED. Conversely a flash with a smaller illumination angle might cause dark areas on the corners of the captured image.

The majority of LED assemblies intended for camera flash applications on the market now have wide illumination angles. There are techniques for fine-tuning the illumination angle through the use of secondary optics, however there are two main drawbacks to adding optics for this purpose. First, secondary optics will cause a loss of approximately 12 percent of the light due to conversion efficiency. Second, the use of secondary optics adds to the cost of the camera phone, takes up additional space and complicates the manufacturing and design process.

Agilent has developed high-brightness white LED light sources, the HSMW C830/C850 Agilent Flash Modules, which are specifically designed to suit the actual requirements of camera phone camera modules. Their unique dome design concentrates the light output from the LED die to form a 60-degree Lambertian radiation pattern, maximizing the light output that falls within a typical camera’s field of view. No secondary optics are needed to redirect the light output. Both major and minor axis produce similar radiation patterns.

The Agilent Flash Module has this characteristic factored into its optical design. The dome design ensures that the overall package radiation pattern remains consistent, regardless of any change in the relative brightness of any of the individual domes.

The module has only two terminals, anode and cathode. Each module incorporates three InGaN LED die; the dice are either connected in parallel (HSMW-C830) or in series (HSMW-C850) within the module. Figure 2 shows how an LED flash can be integrated into a camera phone.

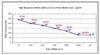

An Agilent Flash Module can be driven at up to 180 mA for a pulse width of less than 200 ms, providing a brightness of 10 lux. Under continuous operation the maximum allowable current is 80 mA, producing a brightness of around 6 lux. Figure 4 shows the relationship between the maximum peak current and pulse width.

Cascading facility

Agilent has designed the HSMW-C850 so that it may be cascaded both mechanically and electrically. The package is purposely designed to be slim so that if the designer would like to cascade two modules together to double the available light output, the combination will occupy a minimum of space. If the modules are cascaded vertically, the combination is only 7.0 mm x 4.4 mm. Some LED flash modules on the market have dimensions of 5.0 mm x 5.0 mm, so that cascading two will occupy about 10.0 mm x 5.0 mm.

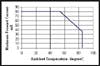

The Agilent Flash Module has a low package thermal resistance that can effectively dissipate heat generated by the LEDs. The module can be illuminated for up to 5 seconds continuously at 80 mA under an ambient temperature of +55 °C. Figure 5 shows the derating curve for Agilent Flash Modules.

The last consideration for choosing an LED flash is to make sure it is compatible with the IR solder reflow process. A device that cannot be reflow soldered requires manual soldering, increasing the manufacturing cost and time. Figure 6 shows the recommended reflow profile for Agilent Flash Modules.