A US Department of Energy Gateway report on outdoor SSL fixtures lighting a section of the Mexican border near Yuma, AZ shows the superior quality of LED lighting.

The US Department of Energy (DOE) has released an initial Gateway report on a solid-state lighting (SSL) trial comparing high-output quartz metal halide (QMH) and LED-based fixtures in a high-temperature outdoor environment. The trail involves three-poles retrofitted with LED luminaires along a stretch of the US-Mexican border fence near Yuma, AZ. Thus far, the SSL fixtures are delivering improved light quality and energy and maintenance savings bolstered by some unexpected nuances of the application at hand.

The DOE noted the uniqueness of the application in the Gateway report, but suggests that many similar applications exist including lighting of correctional facilities, military bases, and even roadways. The trial was intended to evaluate both light quality in the application and the potential for savings. Moreover, the agency sought to evaluate the lighting in the harsh desert environment where during parts of the year temperatures exceed 100°F even at sunset. The heat complicates the challenge of a thermal design in eliminating heat from the LED luminaires and ultimately the semiconductor junction to ensure long-term reliable operation.

DOE Gateway reports detail actual trials of SSL technology in realistic applications and the DOE follows such trials for extended periods. For example, we recently covered a report on a Kansas City, MO street light installation that we first reported on in 2011. Another major outdoor Gateway trial focused on post-top LED luminaires in New York's Central Park.

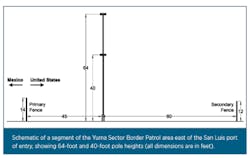

The border application requires high light levels to ensure national security and reliable operation every night. The trial sought to ensure that LEDs could match the legacy system, but in reality the area in which the LED-based poles are located revealed much superior lighting. The poles are located between primary and secondary border fences and illuminate the area between the fences. The gap measures 125 ft with the lighting located 45 ft from the primary fence. Poles are spaced at 180 ft.

The topology of the project means that each luminaire, of a pair mounted on each pole, must cover 11,250 ft2 with an average illuminance of 25 lx. The project design revealed that LED luminaires from Eaton's Cooper Lighting business could handle the task when mounted at 40 ft. The QMH lighting is mounted at 64 ft. The superior beam control of the LED luminaires enabled the lower mounting heights.

Initial testing revealed that the LED poles deliver a better than 100% improvement in vertical illuminance on the primary fence. The DOE noted that average horizontal and vertical illuminance on the secondary fence was slightly worse with the LED poles relative to the QMH poles. The uniformity is superior for the LED-based lighting.

The LED-based system is delivering a 69% improvement in energy efficiency relative to the QMH lighting. Still, the trial has revealed other surprising findings relative to the lower pole heights.

In a new installation, the shorter poles would of course cost less. Even in the retrofit scenario, installation savings came from less lift time and faster installation. The same factor would benefit maintenance operations and even cleaning due to dirt depreciation.

But the lower mounting height also meant that lower peak output was required of the LED luminaire, enhancing energy savings. Moreover, the DOE said the lower mounting height results in less light spill into the night sky.

The high-temperature angle of the trial will require a more lengthy evaluation of the installation. Indeed, the DOE said it would continue to track the performance and either revise the report as needed or issue new report summaries. You can access the full report on the DOE website.