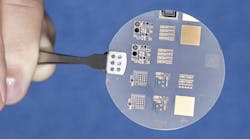

(Niles, IL) A.L.P.s LexaLite® brand, located in Charlevoix, MI has doubled its production capacity in Moldable Optical Silicone (MOS) by adding a new 240-ton tie-barless molding machine to existing 180-ton system. Both machines have advanced production features such as: built-in conveyor, ERC robot, Electro Servo injection and coining technology.

Silicone has performance characteristics that make it a great choice for todays lighting applications. Not only does silicone have an exceptional service temperature range, it is also highly impact resistant and immune to UV degradation. Parts can be designed to self-mount,

self-gasket, and wet against LED lenses to eliminate the air interface. In terms of lighting efficiency, optical silicone features a refractive index of 1.41 and greater than 91% light transmittance. The experts at A.L.P. LexaLite are available to discuss the unique nature of this molding process and any challenging lighting applications.

A.L.P. LexaLite leads the lighting industry in MOS technology. In fact, A.L.P. molds the largest known optical silicone part, which measures approximately 140 square inches. From concept to completion, experts in product design, tooling, silicone molding and testing can quickly and profitably guide your silicone projects.

About A.L.P.

A.L.P. is a leading global supplier of lighting components, offering a diverse line of products for lighting OEMs and the aftermarket. From LED to legacy applications, A.L.P. offers the industry's most comprehensive line of lenses, vapor-proof enclosures, unwired fixture bodies, louvers and baffles, reflectors and extruded sheet products. A.L.P. Brands include Steel Craft, LexaLite®, Reflek and Vantex

Contact:

Lisa Dahm, Director of Marketing Communications - A.L.P.+1 (773) 792-5648

E-mail:

[email protected]Locate more components, packaging & optics vendors in the LEDs Magazine Suppliers Directory

Submit new products, case studies/projects, and other press releases at http://www.ledsmagazine.com/content/leds/en/addcontent.html.

More from A.L.P.:

George Kruggel joins lighting components manufacturer A.L.P.'s LexaLite® brand

Don Gaither joins manufacturer A.L.P. Lighting Components

Submit new products, case studies/projects, and other press releases at http://www.ledsmagazine.com/content/leds/en/addcontent.html.

More from A.L.P.:

George Kruggel joins lighting components manufacturer A.L.P.'s LexaLite® brand

Don Gaither joins manufacturer A.L.P. Lighting Components