Organic light-emitting diode (OLED) technology has gained market interest for general illumination applications due to the ultrathin profile of the OLED modules. Unfortunately, high production costs and inferior performance have resulted in a cost per lumen ($/lm) that remains greater than its LED equivalent.

With OLED and liquid-crystal displays (LCDs) as an inspiration, a new technology is emerging for planar light sources, with lower manufacturing costs and improved performance that can allow LEDs to match the desirable characteristics of OLED in a thin form factor.

Evolution and qualities of OLEDs

While OLED technology has been around since the late 1980s, mainstream OLED came to market back in 2012, with the vision of enabling broader adoption over time due to gradual price decreases and improved performance. Global market leaders such as Philips, Osram, and LG saw the potential for OLED technology to be used across a range of lighting, smartphones, and TVs.

By its nature as a planar light source, OLED offers a low-glare, diffused light as opposed to the high-intensity point light source of LEDs. Moreover, the razor-thin OLED profile of 1.4 mm enables unique luminaire designs not achievable with standard lamps while also creating a recessed appearance from a surface-mounted module. Market analysis has forecasted growth beyond the lightbulb mentality into applications such as embedding light sources into furniture and fabrics, flooring, and stairs (ElectroniCast Consultants OLED Lighting Market Forecast – May 2018).

As human-centric lighting principles have expanded from research & development (R&D) into lighting practice, other qualities of OLEDs bring their appeal to solid-state lighting (SSL). OLEDs have been shown to emit less blue-enriched light than LEDs, which may cause less disruption on human circadian rhythms. In terms of overall health and wellbeing, the glare-free illumination OLEDs provide enables a “healthy” lighting solution. Furthermore, OLEDs contain no mercury or other toxic material, making them environmentally friendly and fully recyclable.

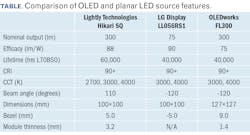

By their third generation, OLEDs have been able to achieve a luminous flux of 300 lm and an efficacy of 75 lm/W (up to 85 lm/W 3000K at a 3000K CCT, with flux in the 65‒100-lm range and luminance of 3000 cd/m-2), >90 CRI, and R9>50. They are available in 3000K and 4000K CCTs and come in three shapes — round, square, and rectangle, with a flexible substrate on the horizon. One of the core ambitions in the development of this technology was to broaden the potential applications for an ultrathin light source. The vision was to offer lighting designers a unique way to flex their creative muscle with a slim form factor.

Why does OLED lighting appear stalled, then?

Despite heavy investment, OLED is struggling to achieve the performance, lifetime, and commercial viability of LED. In fact, by 2017, Philips, Osram, and LG had divested themselves from the market, leaving in question the viability of the technology for the lighting industry. As OLED production costs have failed to come down, and LED performance has advanced, the progress of OLED illumination appears to have stalled. Several factors contribute to the higher cost of OLED light sources.

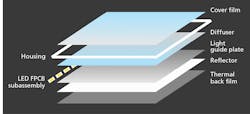

As indicated in Fig. 1, the design structure of an OLED is a key contributor in preventing it from becoming a mainstream component. The manufacturing complexities and high cost of the materials used for the substrate and the OLED compounds themselves are preventing it from broad usage in the general illumination market.

OLED production volume is still small, creating somewhat of a niche market, which tends to alienate most luminaire OEMs. Some R&D has pursued modifications to the manufacturing process, from a sheet-to-sheet method to a roll-to-roll (R2R) method in order to lower costs. However, the R2R process must address certain challenges, like adequately drying the barrier films, so as to minimize degradation.

Another stumbling block is the performance of OLED compared to LED. Today’s advanced LEDs still achieve better light output, lifetime, and efficacy. A US Department of Energy paper shows that the expected lifespan of OLED lighting products goes down with increasing brightness — with an expected lifespan of 40,000 hours at 25% brightness, or 10,000 hours at 100% brightness.

However, there is certainly a market for OLED lighting products in designs like art installations and high-end luminaires where cost and performance do not play a role in their specifications, and where design and visual impact are of more value.

Inspiring advances in planar LED technology

The impactful design of the ultrathin OLED has sparked an inspiration for a new technology that can fill in the blanks of what is missing in OLED. What if an ultrathin planar light source could be produced without sacrificing performance?

In recent years, a new technology has entered the marketplace that utilizes the structure of edge-lit LED panels in a miniaturized form (Fig. 2). It uses a lightguide plate and a unique combination of optical films to maximize LED light output and uniformity as well as controlling the beam angle.

With inspiration from smartphone design, the module is derived from the evolution of LCDs, which have progressed from back-lit illumination to edge-lit LED technology. Over the last 10 years, smartphone displays have become so incredibly thin as to minimize the volume taken up by the display within the smartphone housing. In an improvement on standard LCD technology, LEDs emit light into a lightguide plate where it is then extracted by surface features that prevent total internal reflection.

However, in order to achieve a viable lighting application, optical challenges needed to be addressed with regard to the LED lumen output and the CCT of displays. With display applications, the lumen output needs to be low so as to not be too bright, and display CCT ranges between 8000K and 10,000K, which is too high and not suitable for a lighting module. Module lifetime also depended upon improvements in thermal management.

To continue the vision of OLED, the LED module needed to achieve a physically-similar thin design to maintain its ability to be a surface light source. Also, the electrical layout had to be compatible with standard LED drivers, have the ability to be wired in both series and parallel configurations, and be fully controllable with DALI (Digital Addressable Lighting Interface) and other LED dimming technologies.

The key to achieving these objectives was a combination of optical films along with a lightguide plate. A patented design has been developed to achieve a uniformity in illuminance and beam angle to reduce glare while maintaining a high, functional lumen output (Fig. 3).

For lighting designers and architects, a lighting solution needs to be functional as well as decorative. As with OLED, the ultra-thinness of the planar LED module satisfies the designer’s perspective for creativity, while the functionality of the module fulfills the architect’s specifications. Easy surface mounting is also important. The recommended method is with optically-clear adhesive films applied to the front or back of the module, which is rated IP20 and does not need to be enclosed in a luminaire for indoor applications. The modules’ low power consumption makes them compatible with battery-operated circuits when used alongside an appropriate low-voltage driver.

The first-generation module has achieved an average 450 lm from a 100×100-mm form factor with >90 CRI, R9>65, and an average efficacy of 85 lm/W. In the nearby table, key characteristics and specifications of well-known OLED sources are compared to the planar LED module developed by Lightly Technologies.

Progress in form factor, future prospects

The planar LED technology is currently available in only one shape, but future generations promise to offer more, including color tunability and connecting with Internet of Things (IoT) systems. The major advantage of the planar technology is the lower manufacturing costs. Utilizing inorganic LEDs with the combination of specialized films and lightguides makes it possible to achieve the aesthetics of OLED at a much lower price point. While retaining an ultrathin profile, this new technology provides better outcomes in lifetime hours and performance.

Market indicators show that there is desire for a lighting solution that can be located closer to the user without the blinding light of standard LED sources, such as comfortable reading lights, task-light pendants, desk lamps, and wall sconces. The clean lines, thin surface, and light quality enable the planar LED module to satisfy many designer must-haves. The flat, edge-to-edge surface area makes it easy to discreetly integrate into small spaces (Fig. 4). It requires no additional heat sink and occupies a minimum amount of real estate. Installations where there are space limitations could benefit from the light weight and thin profile afforded by these solutions.

Numerous applications beyond decorative luminaires can be achieved with a planar light source. Market segments include automotive, RV, and aviation as well as traditional residential and commercial spaces. The glare-free, 93-CRI light delivers excellent color clarity, which would enhance also any product on retail display, for example.

As in any industry, SSL designers are always looking for the next great innovation. OLED introduced an intriguing concept in the world of lighting, and it has improved over the years, enabling thinner displays, richer colors, and better performance. It has created opportunities for unique designs in the lighting community, giving luminaire manufacturers freedom of creativity, while providing a functional light source in a compact form factor.

With only one major player, OLEDworks, the commercialization of OLED lighting is seen as moving too slowly to really take off in the general illumination market. Without a substantial increase in demand, the price of the product will remain too high, thereby creating an obstacle in achieving any kind of widespread use in the field.

On the flip side, much like with the evolution of smartphone technology, the R&D put into OLED has shown the way to advance emerging technologies that can fill the void for thin, planar lighting. By using more-efficient LED technology in a similar profile, the world will see an exciting new generation of lighting.

Get to know our expert

LIZ CONGERO is vice president of sales and marketing at Aamsco Lighting, a manufacturer and distributor of multiple lighting lines. Congero has more than 30 years of experience in the lighting industry and with Aamsco. In her time at Aamsco, she has been responsible for developing global vendor and customer relationships, increasing profit margins to maintain competitive pricing, and driving new technologies to market.

Enjoyed this article? Visit our digital magazine for more like this >>