For the second time, LEDs Magazine’s in-person HortiCann Light + Tech conference reverted to an online experience due to ongoing public-health constraints with in-person events. Still, as we reported in 2020, interlinked concerns over climate change, energy consumption, and global food production have stimulated research and investment in technologies and practices for controlled environment agriculture (CEA) — including solid-state lighting (SSL), automation, data analysis, and light science for specific cultivars.

The two-day HortiCann program (held over Sept. 28–29, 2021) reinforced prospects for the expansion of CEA as a technology-driven sector — with greater penetration into commercial grow operations for legalized cannabis and food production, illustrated by practical use-case discussion.

Industry stakeholders, technology developers, and farm operators across various footprints demonstrated how the intersection of SSL and agricultural technology (AgTech) can ultimately deliver on revenue potential, reduced energy consumption, and local, sustainable crop production. In this report, we will focus on the research and discussions that emphasized optimization of equipment and SSL system implementation, which point to a balance between efficiency and maximum yield.

Keynote examines light impact on cannabis stages

Although the conference did not open with its keynote speaker, we will begin our report with that virtual session from the conference. Ricardo Hernandez, PhD, an associate professor at North Carolina State University (NC State), discussed recent cannabis studies designed to investigate the effects of light intensity and quality on the cannabinoid substances THC (tetrahydrocannabinol) and CBD (cannabidiol). Funding and equipment support for the research was provided by GE Current, a Daintree company.

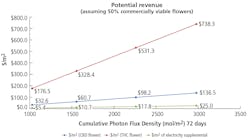

Outlining experiments carried out by PhD student Cristian Collado, Hernandez explained the different outcomes that were achieved as a result of varying the Daily Light Integral (DLI) of Cannabis sativa plants — changing the amount of supplemental LED lighting provided to plants alongside what they naturally received under sunlight in a CEA trial (Fig. 1). DLI is a metric that refers to the total amount of photosynthetically active radiation (PAR) that plants require on a daily basis; their DLI can vary according to species, climate, season, and so forth. (For more on PAR, DLI, and other horticultural-critical metrics, please see our contributed article on the Illuminating Engineering Society’s publication of IES RP-45-21, Recommended Practice: Horticultural Lighting, from Ian Ashdown).

In describing the cannabis studies, Hernandez focused on the vegetative stage (growth of stems and branching) first and then the flower induction and growth stages. The light-treatment trials took place over a 72-day growth cycle. The cannabis vegetative stage incurred an 18-hour photoperiod, while the flowering stage incurred a 12-hour photoperiod.

During a portion of the study, the researchers fluctuated the supplemental LED light during the vegetative stage, with four samples receiving 150, 300, 500, and 700 µmol m-2 s-1 of LED-generated light in addition to the natural sunlight. At the flowering stage, all four samples received an intensified 700 µmol m-2 s-1 of supplemental light.

Hernandez established that the different light-level results showed the vegetative state light level was crucial, with increased branching, biomass, leaf area, and cannabis plant dry mass measured. Secondary branches revealed a greater impact from the supplemental light, which created a bushier plant with larger leaf area, more branches, and thicker leaves. Plants under the varied light quantities during the vegetative stage also showed increased cannabis flower dry mass.

“If you lower your light intensity during the vegetative weeks, you will have a penalty in yield in your flowering,” Hernandez concluded. He proceeded to summarize a cost analysis that applied electricity usage, light intensity variables, and potential market pricing of dry cannabis flower per growing area. Assuming even a 50% yield of commercially-viable flowers, he said the potential revenue more than offset the cost of electricity from the lights (without factoring in any other production/operational expenses, or opex; Fig. 2).

Panelists sow seeds of change on modern farms

On the second day of HortiCann, Cornell’s Greenhouse Lighting and Systems Engineering (GLASE) Consortium director Erico Mattos opened the program with the Plenary panel titled “Voices From the Farm.” In its debut at HortiCann 2020, the panel brought excellent context to the research- and technology-focused presentations by zeroing in on the perspectives of growers facing pain points and emerging needs in modern agriculture and horticulture operations.

The 2021 panel leaned toward a more defined experience, with an assured link to the benefits SSL brought to yields, quality, and controllable outcomes. Rather than relying on a large number of presented slides, Mattos and the panelists explored comparisons between past operations and contemporary methods, with their results and findings over time in applying SSL to operations on very different scales and in varied regions.

A recurring theme amongst the panelists was the ability to overcome seasonality and influence plant growth cycles to produce a quality harvest even during challenging climate conditions. Revolution Farms header grower Tammam Serage commented that, at a Michigan facility that endures harsh winters, LED lighting in the CEA operations allowed the farm to increase the DLI. This in turn reduced the farm’s production cycles of leafy greens from a high of around 52 days down to 36 days. “We can get 14 DLI to about 18-plus any time we want, any time of year” even in the northern Great Lakes region, stated Serage.

Schuyler Greens CEO and farm manager John McMahon underscored the undeniable value of LED lighting in his approximately 20,000-ft2 operation. “As a small operation, I needed to invest in areas that would make me as efficient as possible,” he said, while working under energy supply constraints in Virginia. The switch to red and blue LEDs from high-pressure sodium (HPS) lights was evident in the baby green cultivars resulting in “stout, strong, compact plants that are high yielding,” McMahon observed.

Some of the LEDs audience may be familiar with the work of panelist Tessa Pocock, PhD, a plant scientist whose work has been featured at a previous Horticultural Lighting Conference. Formerly a scientist with the Lighting Enabled Systems & Applications (LESA) Center laboratory at Rensselaer Polytechnic Institute and grower Plenty, Pocock is now applying her experience at Shenandoah Growers.

Pocock said Shenandoah operates multiple facilities for R&D, farm configurations, and nurseries. Modularity in the growing setup has allowed Shenandoah personnel to experiment with various light spectra and intensity levels, as well as test lights from different manufacturers to continuously improve crop outcomes on the larger-scale commercial side. The crux of their work, she said, has demonstrated light uniformity’s “huge impact on yield” — and how crucial it is to test lights, number of fixtures, and spacing to determine realistic light delivery to crops.

“I’m talking to lighting manufacturers about how we can increase uniformity and [improve] light mapping of these fixtures,” Pocock said. She emphasized how important it is for growers to be confident in what they are applying to their crops.

Pocock and Serage established that one key issue still for growers is holding lighting manufacturers accountable for their performance claims. Again, as a small grower representative, McMahon underlined the need for light testing with quantum sensors and access to SSL benchmarks for proper comparison of LED products.

CEA goes to college

A motley assemblage of experts proved inspiring in the final HortiCann Light + Tech session, delivering more insights into institutional and commercial opportunities for CEA, including how to comply with local regulations in a way that makes technology an impactful investment.

A novel partnership between Auburn University (AU) professor Daniel Wells and campus dining and concessions director Glenn Loughridge disclosed how the AU horticultural/agricultural education program began to collaborate directly with dining operations for localized food production on a campus of about 50,000 people.

Loughridge said the sense of community and pride among the AU campus, administration, and other supporters has helped to grow its agricultural education program beyond its traditional field/farm focus to an initial aquaponics project and more recently to vertical farming, enabled by two shipping container farms supplied by Freight Farms (Fig. 3). As LEDs has reported previously, Freight Farms’ business proposition is in selling what it calls “turnkey farms” that leverage SSL and software controls, efficient water and nutrient management, and vertical farming strategies to enable small, sustainable produce operations.

Loughridge and Wells both noted that benefits of such an on-campus program include not only hands-on application of plant science for the students but also better placement for grant funding opportunities, and the ability to scale the growing operations over time.

Wells said the AU operation is currently producing about 100 lb of spring-mix greens per week from just one of its greeneries, which were established in April 2021. Loughridge added that the program has enabled collaboration between campus chefs, farm faculty, and participating students to deliver excellent quality, local produce unaffected by seasonal climate conditions.

Put policy to work for successful grow facilities

Moving to energy code and regulations that can impact growers, Gabel Energy consultant Gina Rodda delivered the message that forward-looking California energy policies can help other regions to see what could be coming for them and meet any building and equipping challenges early on in the CEA planning process. As Maury Wright reported in 2020, “The ongoing activity in the [California Energy Commission] for its 2022 Title 24 code cycle that would go into effect in January 2023 includes a virtual mandate that all new horticultural lighting use LED sources”.

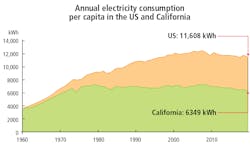

The energy and environmental programs in California have a history of informing regulatory policy and code in other US regions. Interestingly, Rodda showed a graphic sourced from the California Energy Commission’s (CEC’s) 2022 Building Efficiency Summary that hammered home the vast policy and utility differences between California and other US states, with California residents consuming 31% less energy compared to the average US resident (Fig. 4).

Rodda explained how complex the application of code requirements can be, since they not only affect the specification of energy-consuming lighting but also structural materials and even the classification of different types of grow spaces. Intimate knowledge of code in the state of California, for example, means knowing the differences between a “controlled environment horticulture (CEH) space,” a “conditioned greenhouse,” and an “indoor growing” space. The distinctions are not as subtle as one might think and are mainly grounded in measurable area, environmental regulating equipment, and natural daylight access ratio.

More details on the CEC 2022 Building Energy Efficiency Standards can be found at bit.ly/3ney5xZ. But consultancies versed in energy-efficiency policies can help CEA operators reduce their environmental footprint and manage costs effectively while maximizing their profitability and long-term prospects, she said. Rather than viewing utilities and energy regulation agencies as oppositional to their business, growers can empower themselves with the best logistical information to future-proof their facilities and equipment, while reaping the economic benefits of any incentives available, Rodda summarized.

Heat and light — Decoupling demands for energy balance

Finally, head grower Adam Shinners of SuperiorFresh and Fluence by Osram director of horticulture services Abhay Thosar, PhD, spoke about the benefits of environmental control in a unique aquaponic and greenhouse operation based in Wisconsin. (Note that HortiCann took place prior to the more recent announcement that ams Osram was selling off the Fluence business unit to one-time horticultural SSL competitor Signify).

SuperiorFresh is an unusual organization in that it operates accredited facilities designed to implement sustainable practices in both its aquaculture (salmon farming) and horticulture (greens production) operations. Practicing what is known as “regenerative agriculture,” SuperiorFresh manages its farming impact on the local land with reclaimed nutrients and minimized water runoff; organic feed and plant nutrients; and farm waste composting. Why do we mention this here? Simply put, CEA and AgTech demand ever-more sophisticated solutions to balancing the need for human food production with those of the surrounding ecosystem — to safeguard natural resources and deliver safe, reliable food sources — which could not be possible without the curiosity and drive for progress that contemporary producers bring to the modern Ag sector.

Back to the presentation, Shinners echoed others’ experiences with how the facility’s use of LED lighting helped to manage operational costs in a cooler region. Focusing mainly on the greenhouse operation, both Shinners and Thosar addressed the question of the heat produced by HPS lights and growers that rely on that excess heat to condition the indoor grow environment for specific cultivars. Shinners said the lettuce varietals grown at SuperiorFresh are not heat tolerant, so using HPS in the greenhouse would require the excess heat to be exhausted — which is more energy-demanding than the natural gas boilers with set points that keep the crops comfortable in the greenhouse. “It’s cheaper to add the heat with a natural gas system” than it is to over-light with energy-demanding HPS and then remove the excess heat, he explained.

The robust dimming functions of properly designed SSL systems also help balance energy consumption, Shinners added. Thosar then summarized the needs of the greenhouse-grown leafy greens versus what they receive seasonally via natural sunlight. In summer, natural sunlight in the Wisconsin region where SuperiorFresh is located can deliver between 30–35 mols of PAR per day (average) — this is before one accounts for the greenhouse materials, which only allow about 22–25 mols/day to be received by plants through the structure (actual average DLI). Again, that’s representative of an average summer’s day. In the winter, that PAR drops to between 8–10 mols/day from the sun and then a resulting DLI of 5–6 mols/day in the greenhouse.

Thosar explained that according to Fluence’s studies, leafy greens and lettuce typically require the following for different stages of growth:

- Propagation: 8–12 mols/day

- Transplant: 12–15 mols/day

- Finishing: 14–18 mols/day

He then showed the difference in light output between HPS and LED. A typical 1000W horticultural HPS fixture outputs a range of 32–35% of usable light (as opposed to photons converted to convection or radiant heat), depending on the efficacy of the fixture, said Thosar, whereas a 600W horticultural LED fixture can output between 58–63% depending on the LED efficacy.

Wasted photons are not cost effective, reiterated Thosar, which requires a different way of thinking about what energy is being used for in the grower operation. “When you decouple the light and heat, you have much better environmental control” when using LEDs rather than HPS, he said. Furthermore, to those who say they need the heat from the HPS in their greenhouses and indoor farms, Thosar responded, “I have a furnace to heat my house; I don’t heat my house with an oven” because it’s not an efficient way to use the equipment to achieve the objective.

Conclusion

This article represents only a portion of what HortiCann Light + Tech speakers and additional resources offered. LEDs Magazine continues to review horticultural and AgTech topics and trends, and to consult with prospective partners and industry stakeholders on a program for 2022. We look forward to bringing our audience more information on the next event in the coming weeks after this publication.

As Pocock remarked back at the 2017 Horticultural Lighting Conference, “The future is knowledge-based controlled environment agriculture.” It is evident that the current state of the art in SSL, controls, and applied research can enable smarter and more efficient agriculture operations. What will we see in another five years?

CARRIE MEADOWS is managing editor of LEDs Magazine, with 20 years’ experience in business-to-business publishing across technology markets including solid-state technology manufacturing, fiberoptic communications, machine vision, lasers and photonics, and LEDs and lighting.