Ichikoh simulates LED headlights in cars

Ichikoh Industries Ltd. has developed a simulation technique to greatly accelerate the design and prototyping of LEDs for automotive headlights.

LEDs have already been used in such low-illumination applications as interior lamps and rear lights. But in their quest to design smaller and lighter cars with more design freedom, automakers have now also begun to call for the development of powerful LEDs that can be used as headlights.

A serious problems with LEDs is the decrease in brightness which occurs when they are heated, so for automotive headlight applications it is necessary to optimize heat dissipation and methods for cooling the LED lamps.

Ichikoh's new simulation technology analyzes heat flow and helps cut back on the need for prototyping, shortening the development cycle by up to 75%.

The technology, which two years to perfect, applies the analysis techniques of computer-aided engineering (CAE) to measure heat distribution and help determine optimal solutions for heat dissipation and cooling. Ichikoh claims the simulations yield values that differ by less than 2% from the measurements of actual prototypes.

The company plans to use this simulation technology to speed development of a variety of LED headlights at low cost. The goal is to have products ready for market in 2006.

Risho Kogyo unveils improved substrate material

Risho Kogyo Co. has developed a white-colored, copper-clad epoxy/glass laminate board capable of increasing the longevity of LEDs by up to ten times when used as substrate material.

The board is capable of maintaining 92% of its light reflection efficiency, even after 500 hours of exposure to ultraviolet rays. Existing boards tend to lose their light reflection efficiency by 60% after the same UV exposure, and also are less efficient after exposure to heat.

The board's base consists of a glass fiber covered with epoxy resin and titanium oxide. After the drying process, the board is covered with copper foil, which is then etched to form circuits on the board.

Mitsubishi Chemical develops white LED with UV chip

Mitsubishi Chemical has developed a prototype energy-saving white LED lamp capable of emitting natural sunlight-like white light.

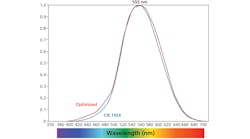

The company has combined a near-ultraviolet LED with its proprietary fluorescent substances that emit at red, blue and green wavelengths.

The red-emitting fluorescent substance is a europium ion complex, which can enhance the balance of the three colors and thereby help them produce natural sunlight-like white colors.

Mitsubishi Chemical plans to commercialize the white LED for use as a back light in household lighting equipment as well as in large LCD TV sets in the near future.

Oki Data to make color LED printers in China

Oki Data will begin shipping color LED printers from Oki Electric Industry (Shenzhen) Co., Ltd. this month. The company is moving into China, where many component makers already operate, in order to reduce production costs as well as time-to-market.

Oki Data plans to produce 40,000 color LED printers in fiscal 2005 at Oki Electric Industry (ShenZhen) which manufactures monochrome LED printers and dot-matrix printers.

The company currently manufactures color LED printers at Oki Data Manufacturing (Thailand) Co., Ltd., and shipped more than 200,000 units in fiscal 2004. Oki Data forecasts that sales of color LED printers combined with color multi-function printers will reach 350,000 units worldwide in fiscal 2005.

By having color LED printer production operations in both Thailand and China, Oki Data will be able to better cope with risks.