L-Prize seeks to advance U.S. lighting manufacturing opportunities, with third phase underway

The U.S. Department of Energy’s (DOE’s) Building Technologies Office recently opened the third phase of its revamped L-Prize lighting competition. The Manufacturing & Installation Phase will take place over 16 months, in which participants will develop and install new interoperable lighting products that meet the program’s technical requirements.

The L-Prize program is administered by the National Renewable Energy Laboratory (NREL) with technical assistance provided by Pacific Northwest National Laboratory (PNNL). Structured around three phases — Concept, Prototype, and Manufacturing & Installation (M&I) — the competition is designed to encourage innovative lighting systems that demonstrate progress in decarbonization, reduce energy consumption, and improve the built environment for all occupants.

Luminaire and connected system criteria diverge

Two tracks were designated to recognize luminaires and connected systems separately, with some differences in requirements versus additional points considerations.

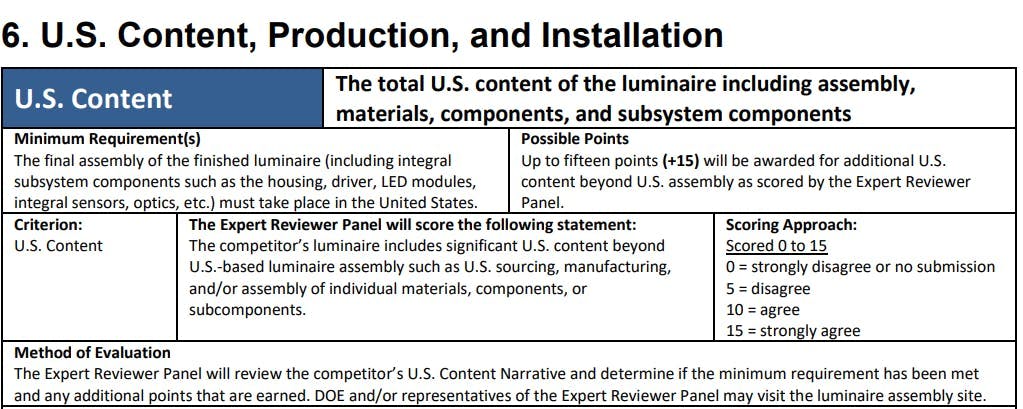

Luminaires are judged on efficacy, quality of light, connectivity, product life cycle, technical innovation, and U.S. content, production, and installation, with some mandatory requirements and additional points awarded for optional requirements (see image above).

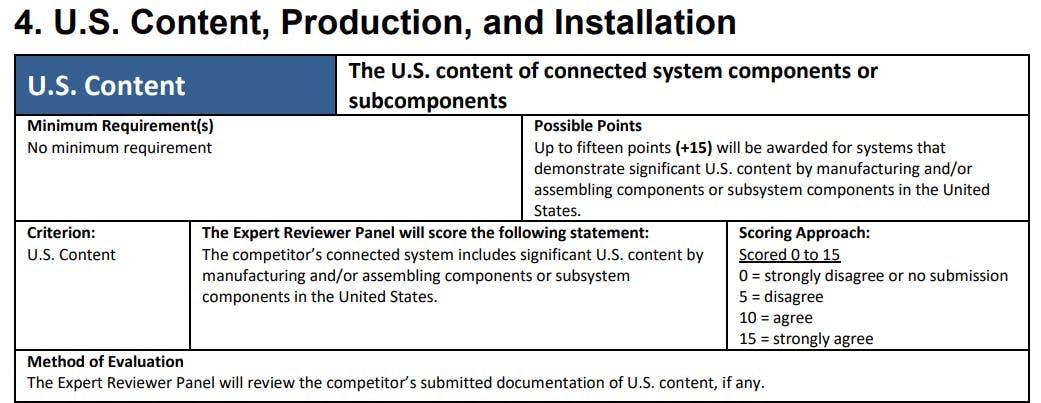

Connected systems are evaluated on connectivity features, product life cycle, technical innovation, and U.S. content, production, and installation criteria, with some mandatory requirements and optional points opportunities (see image below).

As part of the DOE American-Made Challenge program, the L-Prize competition requires participants, teams, or organizations to be legally residing in or based in the United States, and entries will be evaluated in part based on their U.S. content. In short, integral sub-components for a luminaire track submission must be sourced and assembly of the luminaire must take place in the U.S. (top image from Appendix A of the M&I Phase guidelines, available from the American-Made Challenge website). However, connected systems track submissions are not subject to the exact same criteria, showing no minimum requirement in the U.S. content section (bottom image from Appendix B). Connected systems entries do require a bill of materials stating the countries of origin for all system components, and they will be eligible for additional points where U.S. content serves.

Manufacturing and assembly opportunities

LEDs Magazine spoke with PNNL’s Gabe Arnold, technical lead for the L-Prize program, to gain more insight into the prospects for domestic sourcing and assembly, and the potential influence on sustainability initiatives as a result of the competition.

“[We know that] based on the 2020 DOE LED Manufacturing Supply Chain Report, the U.S. luminaire market is estimated at $10.7 billion,” Arnold emailed before the discussion. “Of this, in 2019, $3.4 billion was imported from China, and $1.25 billion from Mexico. The remainder was imported from other countries or manufactured domestically.”

Arnold continued, “The current best estimate from this data is that at least $1.2 billion of luminaire manufacturing occurs in the U.S., and potentially as high as $3.8 billion.”

On today’s call, he noted that a key goal of the L-Prize program is to demonstrate and grow U.S. manufacturing capabilities, and the luminaire track was best positioned to require U.S. content and assembly for submissions.

Arnold said that the difference in requirements between the luminaire and connected systems tracks stems from the large overseas manufacturing market share for luminaire electronic subsystem components and electronic components for connected systems, particularly in Asia. “That [supply chain] is not something that the L-Prize is expected to significantly influence,” he said. Still, significant opportunities remain for other luminaire parts to be domestically produced and sourced — thus the stricter guidance for luminaire submissions. Housings, optics and lenses, and wiring can all be prime sources for U.S. content, he observed.

“Luminaires are [often] manufactured from aluminum or steel and there are domestic sources that can be procured,” Arnold explained. “But one of the things that we saw with the Prototype Phase — which was really innovative — was a biodegradable, low-carbon luminaire from a company called Lightly [which was] made out of locally harvested wood, where the luminaire was being manufactured and assembled.”

Another key component of the L-Prize program is the mandatory luminaire life-cycle assessments (LCAs) and related environmental product declarations (EPDs). “When you deliver those life cycle assessments and the resulting EPDs, you have to take into account the environmental impacts of transporting the luminaire and components from wherever they originated to the place that they’re actually assembled and manufactured,” Arnold said. These key criteria can also gain entrants points toward sustainability innovations and potentially circularity, as replaceable luminaire components are also mandatory.

Concerning the opportunity for domestic sourcing and content in connected systems, Arnold reiterated that there was uncertainty about the availability of U.S. manufactured electronic components, such as “electronic chips and circuit boards that go into sensors, gateways, or controllers. […] But we want to know if there is an opportunity to at least do the assembly of the overall gateway or some other parts here in the U.S., and we don’t really have any data on that,” he said. Rather than demand domestic parts for both tracks, he said, the program aims to explore and support the capabilities for U.S. manufacturing and assembly.

As many as four competitors will share a $10 million award for the M&I Phase, planned to be announced in early 2026. See our resources box for more information and links.

Key dates & resources

The L-Prize M&I Phase opened on April 3, 2024. Register for an informational webinar hosted by the organizers on May 8 regarding entry requirements and other important details. Forms and updates can be found at https://www.herox.com/LPrize.

M&I Expression of Interest forms due: Oct. 1, 2024

Intent to Submit forms due: April 1, 2025

Connected systems pre-testing: June-July 2025

Submissions due (all tracks): Aug. 5, 2025

Winners announcement (anticipated): February 2026

*Dates are subject to change at the discretion of the L-Prize program administrators.

CARRIE MEADOWS is editor-in-chief of LEDs Magazine, with 20-plus years’ experience in business-to-business publishing across technology markets including solid-state technology manufacturing, fiberoptic communications, machine vision, lasers and photonics, and LEDs and lighting.

Follow our LinkedIn page for our latest news updates, contributed articles, and commentary, and our Facebook page for events announcements and more. You can also find us on the X platform.

Carrie Meadows | Editor-in-Chief, LEDs Magazine

Carrie Meadows has more than 20 years of experience in the publishing and media industry. She worked with the PennWell Technology Group for more than 17 years, having been part of the editorial staff at Solid State Technology, Microlithography World, Lightwave, Portable Design, CleanRooms, Laser Focus World, and Vision Systems Design before the group was acquired by current parent company Endeavor Business Media.

Meadows has received finalist recognition for LEDs Magazine in the FOLIO Eddie Awards, and has volunteered as a judge on several B2B editorial awards committees. She received a BA in English literature from Saint Anselm College, and earned thesis honors in the college's Geisel Library. Without the patience to sit down and write a book of her own, she has gladly undertaken the role of editor for the writings of friends and family.

Meadows enjoys living in the beautiful but sometimes unpredictable four seasons of the New England region, volunteering with an animal shelter, reading (of course), and walking with friends and extended "dog family" in her spare time.

![L-Prize luminaire track mandatory minimum and points-earning requirements. (Source: Lighting Prize [L-Prize] Manufacturing & Installation Phase Rules; April 3, 2024.) L-Prize luminaire track mandatory minimum and points-earning requirements. (Source: Lighting Prize [L-Prize] Manufacturing & Installation Phase Rules; April 3, 2024.)](https://img.ledsmagazine.com/files/base/ebm/leds/image/2024/04/6616e326af48c6001fa1c7c0-luminaire_track_requirements.png?auto=format,compress&fit=max&q=45)

![L-Prize connected systems track mandatory minimum and points-earning requirements. (Source: Lighting Prize [L-Prize] Manufacturing & Installation Phase Rules; April 3, 2024.) L-Prize connected systems track mandatory minimum and points-earning requirements. (Source: Lighting Prize [L-Prize] Manufacturing & Installation Phase Rules; April 3, 2024.)](https://img.ledsmagazine.com/files/base/ebm/leds/image/2024/04/6616e38295378d001ef1a701-connected_systems_track_requirements.png?auto=format,compress&fit=max&q=45)

![The DesignLights Consortium continues to make progress in shifting outdoor lighting products and implementation practices toward a more restrained and thoughtful strategy. [Image does not represent a DLC qualified fixture.] The DesignLights Consortium continues to make progress in shifting outdoor lighting products and implementation practices toward a more restrained and thoughtful strategy. [Image does not represent a DLC qualified fixture.]](https://img.ledsmagazine.com/files/base/ebm/leds/image/2024/08/66be810888ae93f656446f61-dreamstime_m_265700653.png?auto=format,compress&fit=&q=45&h=139&height=139&w=250&width=250)