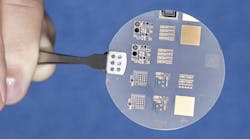

The new pilot LED demonstration plant features BluGlass’s first commercial-scale semiconductor reactor fitted with its home-grown Remote Plasma Chemical Vapour Deposition (RPCVD) technology. RPCVD is used to grow GaN-based LED materials. The company plans to use the plant to demonstrate large cost benefits to LED device manufacturers, with the aim of winning substantial equipment supply contracts, licencing deals and royalty income.

In his speech, Garrett said that LEDs will "play an increasingly important role in the future of lighting worldwide, including in our homes. The BluGlass process is an Australian innovation, and advances in this area by this leading edge company will make significant inroads in reducing the costs of LEDs."

Garrett said that one of the key barriers restricting the uptake of LEDs has been their cost. "And up-front cost is an important issue when it comes to deploying energy-efficient technologies," he said. "The Federal Government is committed to taking energy efficiency mainstream."

On June 5 this year, Garrett announced that the planned phase-out of inefficient lighting in Australia will be brought forward to November 2008, when the import of inefficient incandescent bulbs will be restricted.

"Our focus right now is on encouraging Australians to switch to existing efficient alternatives, like compact fluorescent lamps, but it's also on fostering innovation, and that's why the work of companies like BluGlass has the potential to become part of taking energy efficiency mainstream," said Garrett.

BluGlass was created from research at Sydney's Macquarie University. In 2007 the Australian Government awarded BluGlass a $5 million grant to progress its innovative technology.

"Our new demonstration reactor is designed to show the world that BluGlass has a commercially viable and attractive technology," said BluGlass’s Chairman Mike Taverner. "We expect that among many applications, this ground-breaking Australian development will have an important global role in improving the efficiency with which we use energy in lighting, with flow-on benefits to the environment."

BluGlass recently appointed Giles Bourne as CEO after a period as interim CEO. "With the launch of our new plant, we will invite top level corporations from Asia, the US and Europe to come and actually exactly see what we can do," said Bourne. "We have delivered on all of our promises to investors about commercializing our technology, and now we are now lifting our sales push in the global market."

BluGlass says it is is already in advanced discussions with universities for orders for its pilot-scale reactors, a smaller version of its commercial technology that also incorporates its RPCVD technology. The company’s plan is that customers, including commercial enterprises and universities, can buy pilot reactors to conduct their own testing and speed the uptake of BluGlass’s patented technology.