10,000 lumen high bay that weighs just 2.5kgs including the heat sink

Sheffield, UK - Litecool has produced a demonstration LED high bay unit using some of its thermal management technology. The luminaire weighs just 2.5kg and pushes out over 10,000 lumens.

Litecool is well known for its innovative approaches to thermal management. Their passive thermal technologies seem to magic heat away from the LEDs keeping them at least 20 degrees cooler than similar systems. However, as CEO James Reeves says, “the market is generally happy with running LEDs at their maximum temperature, so instead of running them cooler we can run them harder!” Low thermal resistance systems [°C/W] means that you can push a significantly higher power [W] through the system before you reach the operating temperature [°C]. Elwyn Wakefield, chief packaging engineer at Litecool says, “Most LEDs are actually under run so not to exceed the maximum temperature, with our approach we have shown that we can put up to 330% more power through the LED and it still runs within its normal temperature range”.

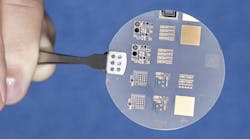

So what does this really mean – Litecool has now shown us with this high bay luminaire. The company has designed a luminaire to produce 10,000 lumens whilst being as light as possible and staying within operating temperature of the LED – apparently sticking to its strap line of “Bright, Lighter, Cooler” and indeed it has. At just 2.5kg including all 126 LEDs, secondary optics (26° FWHM) and most importantly a contemporary styled heat sink – it is certainly market leading in lumens/kg. Although Litecool decided to run the LEDs in this system at “normal operating temperatures” rather than 20°C cooler they aimed for 100°C junction temperature (most junction temperatures are usually 125-150°C) and measurements have shown the LEDs actually run at 96°C. Obviously Litecool’s idea of hot is still cooler than most peoples’.

When looking at this high bay unit the stylized heat sink would appear to be the main thermal management technology; however Robert Corbin, project engineer at Litecool, says that is not the case: “We are not really heat sink designers, this heat sink only works because of the heat management we have built into the LED array itself. We have optimized heat spreading from the bare die through to the fin tips and so the heat sink design is a consequence of the thermal engineering throughout the system.”

So is this the best that can be achieved? James Reeves, CEO at Litecool, says no: “I am particularly pleased with this high bay unit as it only includes the technologies that are available from Litecool right now. However I have no doubt that we could make this even Brighter, Lighter and Cooler in the very near future.”

About Litecool.

Litecool is a leader in thermally efficient LED packaging and thermal design. By focusing on thermal management and performance engineering at package level it has helped its customers to achieve breakthrough performance in lumen density, efficiency and reliability enabling a new generation of luminaires which are sleeker, cooler and more cost effective.

Sheffield, UK - Litecool has produced a demonstration LED high bay unit using some of its thermal management technology. The luminaire weighs just 2.5kg and pushes out over 10,000 lumens.

Litecool is well known for its innovative approaches to thermal management. Their passive thermal technologies seem to magic heat away from the LEDs keeping them at least 20 degrees cooler than similar systems. However, as CEO James Reeves says, “the market is generally happy with running LEDs at their maximum temperature, so instead of running them cooler we can run them harder!” Low thermal resistance systems [°C/W] means that you can push a significantly higher power [W] through the system before you reach the operating temperature [°C]. Elwyn Wakefield, chief packaging engineer at Litecool says, “Most LEDs are actually under run so not to exceed the maximum temperature, with our approach we have shown that we can put up to 330% more power through the LED and it still runs within its normal temperature range”.

So what does this really mean – Litecool has now shown us with this high bay luminaire. The company has designed a luminaire to produce 10,000 lumens whilst being as light as possible and staying within operating temperature of the LED – apparently sticking to its strap line of “Bright, Lighter, Cooler” and indeed it has. At just 2.5kg including all 126 LEDs, secondary optics (26° FWHM) and most importantly a contemporary styled heat sink – it is certainly market leading in lumens/kg. Although Litecool decided to run the LEDs in this system at “normal operating temperatures” rather than 20°C cooler they aimed for 100°C junction temperature (most junction temperatures are usually 125-150°C) and measurements have shown the LEDs actually run at 96°C. Obviously Litecool’s idea of hot is still cooler than most peoples’.

When looking at this high bay unit the stylized heat sink would appear to be the main thermal management technology; however Robert Corbin, project engineer at Litecool, says that is not the case: “We are not really heat sink designers, this heat sink only works because of the heat management we have built into the LED array itself. We have optimized heat spreading from the bare die through to the fin tips and so the heat sink design is a consequence of the thermal engineering throughout the system.”

So is this the best that can be achieved? James Reeves, CEO at Litecool, says no: “I am particularly pleased with this high bay unit as it only includes the technologies that are available from Litecool right now. However I have no doubt that we could make this even Brighter, Lighter and Cooler in the very near future.”

About Litecool.

Litecool is a leader in thermally efficient LED packaging and thermal design. By focusing on thermal management and performance engineering at package level it has helped its customers to achieve breakthrough performance in lumen density, efficiency and reliability enabling a new generation of luminaires which are sleeker, cooler and more cost effective.

Contact:

Litecool+44(0)-114-2216-001

Locate more packaging & optics vendors in the LEDs Magazine Suppliers Directory

Submit new products, case studies/projects, and other press releases at http://www.ledsmagazine.com/content/leds/en/addcontent.html.

More from Litecool:

Litecool trials Black X dielectric material for packaged LED thermal management

Litecool develops LED packaging concept with vertical dielectric that reduces thermal resistance