Turn back the clock a decade, and you could find myriad approaches to thermal mitigation in early LED-based lighting products. Remember replacement lamps that weighted 5 lb or more because of the heat sink? LED efficacy increases combined with material science advancements have mostly hidden the thermal elements of solid-state lighting (SSL) products these days. But you will still find active cooling in high-power fixtures such as replacements for 1000W high-pressure sodium (HPS) lamps in applications such as horticultural lighting. Other demanding applications include sports venue lighting, entertainment lighting, and high-end retail. Here we will look at a new approach to active cooling for LEDs based on a linear fan.

Turning back the clock again for that decade, fan technology was being utilized in a lot of SSL projects. There were innovative startup companies with new approaches to thermal mitigation. For example, a company called Nuventix was promoting coolers they branded SynJet that used a vibrating membrane to generate airflow. Over the years, we have seen water-cooled approaches and more. A feature article from 2013 covered many of the thermal products demonstrated at Strategies in Light that year.

By 2015 or so, the thermal battle had become more about materials as LED efficacy had increased. Higher efficacy meant that product developers could use fewer LEDs in an SSL product or operate the LEDs at lower drive currents. Either act would reduce the thermal load. Still, reliable product design required care be taken with the thermal issue, as detailed in a Developer Forum article we published.

Material science

On the materials side of things, we’ve seen incredible developments. Thermoplastic materials replaced metal heat sinks in replacement lamps and common luminaires such as downlights. And the substrates that LEDs are mounted on have gone through innovation cycles. Adura LED Solutions has made a business out of manufacturing thermally-enhanced substrates based on its SinkPad technology that in some cases eliminates the need for a heat sink or can be combined with common heat-sink form factors.

Now don’t misunderstand. There are plenty of applications where heat sinks and even active cooling remain a requirement. Consider spotlights for entertainment applications. Those products use many high-power LEDs integrated in an array of some sort. Street lights produce high output, operate for long hours, and can be in a challenging ambient thermal environment — for instance, operating in a desert city.

Product developers can turn to a company such as MechaTronix to address many of the notorious high-power applications. The company has offerings for spotlights, outdoor area lighting, sports venue lighting, and more. The portfolio ranges from standard passive heat sinks to designs that use heat pipes to products with an active fan element.

An article we ran recently on sports lighting tied to the recent Super Bowl illustrates one approach to thermal design. The luminaire design in that article used heat pipes, an active fan, and thermal fins to dissipate heat.

Horticultural application

To consider a novel active approach to thermal mitigation, let’s turn to horticultural lighting. Plants need a lot of light when grown indoors or even in a greenhouse setting where electrical lighting is supplemental to the sun. As our keynote from the HortiCann Light + Tech conference addressed last October, a cultivar such as cannabis needs extreme levels of light. And such lighting operates for very long hours.

Now some horticultural applications don’t have a thermal issue. Vertical farming of leafy greens uses lower light levels and LEDs spread linearly. Even some cannabis growers are moving toward new topologies in a grow room using LEDs spread on large rectilinear structures. But the standard in cannabis lighting has been the 1000W double-ended HPS fixture. Replacing that fixture on a one-for-one basis with SSL requires a lot of LEDs packed into a relatively small footprint.

Of course, you could use traditional rotary fans to cool such a fixture. But such fans may not match the reliability of the rest of the SSL systems while being necessary for cooling the rest of the system (LEDs and driver) to meet the specified lifetime. Indeed, some growers have experienced issues with SSL installations on several fronts and fans have been one source of frustration.

Linear fan

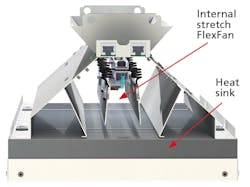

A thermal-focused company called Perpetua has created a new concept that it refers to as a FlexFan — essentially a linear fan. Perpetua says it developed the FlexFan to eliminate rotary bearings, which are the primary failure mode of rotary fans at high temperature and in harsh atmosphere environments. The fan is the basis of a thermal subsystem that is described as an impingement fan-sink design. The subsystem assembly consists of a rectangular heat sink that would mount with a thermal interface material to the rear of the LED substrate — such as a thermally-enhanced printed circuit board (PCB). The linear fan mounts on top of the rectangular heat sink down one center axis of the rectangular assembly and stretching the full length of that axis. The fan creates airflow that impinges through the centerline of the heat sink directly to the PCB and disperses outwardly, carrying heat away from the PCB.

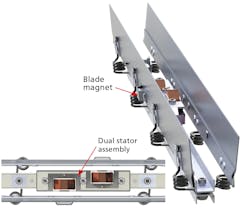

The fan concept is based on two identical rectangular blades made from rigid metal. The blades face one another and are attached to the frame of the device by a series of coiled springs. Those springs allow the blades to pivot and move toward one another or away from one another. And such an oscillation delivers air flow off the blade tips as they oscillate back and forth. These springs are designed to always operate below their fatigue limit, which in the engineering field of life and reliability is referred to as infinite life.

The design places a pair of stator coils — in motor parlance — one for each blade mounted on the frame assembly. On the outside of each blade, a permanent magnet is mounted directly aligned with the stator on the opposite side of the blade. A sinusoidal voltage input to the stators results in what Perpetua calls a bi-polar current in the stators. The current reverses direction twice during each cycle of the sinusoid. During one half cycle, the blades are pulled toward each other and during the next half cycle they are repelled.

Perpetua has developed a controller PCB for the operation. The frequency of the input signal is controlled to match the mass-spring resonance frequency of the blade assembly. Driving the fan at this mechanical resonance frequency requires the lowest drive forces, and therefore less power input or better energy efficiency. The voltage of the input can be varied to alter the stroke amplitude of each blade which in turn varies the airflow rate. The blades remain rigid with only the springs flexing to allow the blades to pivot and oscillate.

Fan performance and benefits

Engineers at Perpetua have tested the concept and documented pressure and flow performance comparable to rotary fans using fan testers and methodology in line with standards and recommendations of the American Society of Mechanical Engineers (ASME). Ultimately, performance would depend on the size of the blades, frequency, stroke, and more. Like rotary fans, linear fans have their own fan laws; airflow varies linearly with stroke and frequency; pressure varies linearly with stroke and with frequency squared.

For horticultural lighting, Perpetua has designed a specific model of the FlexFan that fits conveniently in the footprint of the 1000W HPS fixture. The design relies on 19-in.-long blades, operates at 38 Hz, and has a blade-tip stroke of 17 mm. That configuration delivers 85 CFM (cubic feet per minute) of airflow. Power consumption is less than 5W and lifetime is specified at seven years.

The fan and heat-sink assembly has been integrated into a horticulturally-targeted luminaire. Horticultural-lighting specialist AGxano has brought that luminaire to market as the Kosmos Series that uses CABA Tech’s patented spectrum technology.

Perpetua, meanwhile, touts the benefits of the FlexFan technology as a better reliability match for SSL systems than are rotary fans. And there are other benefits as well. Perpetua said that rotary fans collect particulate matter such as pollen and are difficult to clean. In some cases, such rotary fans might lead to unwanted cross-pollination and circulation of pathogens. In a linear fan, the airflow passes over the blades in a path parallel to the planes of the blades, which results in self-cleaning operation.

The SSL niche that requires active cooling will certainly continue to shrink, although most experts agree that the LED industry has nearly exhausted large efficacy gains. Developers working on high-output lighting may want to consider the linear fan potential.

LEDs Magazine chief editor MAURY WRIGHT is an electronics engineer turned technology journalist, who has focused specifically on the LED & Lighting industry for the past decade.

Enjoyed this article? Visit our digital magazine for more like this >>