The US Department of Energy (DOE) has published new research that is based on analysis of LM-80 testing datasets of 223 separate packaged LEDs to discern component behavior over time relative to lumen maintenance and to chromaticity shift. The analysis considers four different package types that generally correspond to what we would call mid-power, high-power, chip-on-board (COB), and chip-scale package (CSP) LEDs. The analysis reveals relatively predictable and acceptable lumen maintenance performance for all LED types but vastly different chromaticity shift characteristics — data that can be vital to solid-state lighting (SSL) manufacturers, lighting designers/specifiers, and others.

The authors of the report are Lynn Davis, a fellow in engineering research at RTI International, and Monica Hansen, principal at consultancy LED Lighting Advisors. That same duo was behind a similar report back in 2015 that was solely focused on lumen maintenance. We did not publish a news story on that earlier report, but we did publish a contributed article from the authors of the report leading up to a presentation the duo made at Strategies in Light 2015.

Since the earlier report, it’s become increasingly evident that chromaticity shift, especially in applications such as retail or perhaps museum lighting, can essentially render an LED to be at the end of useful life just as easily as can lumen depreciation. Thus the new report examines both failure modes and also adds coverage of CSP LEDs. The report recognizes the long understood fact that LEDs don’t often fail catastrophically yet degrade to a point where they no longer produce illumination that’s useful for the application at hand.

The report is completely focused on phosphor-converted white LEDs (pc-LEDs). The four package types studied include polymer-based (sometimes referred to as plastics and common in mid-power), ceramic-based (high-power), COB-array, and two types of CSP LEDs. We published our first detailed article on CSP technology back in 2015 and many other articles since. Some CSP LEDs emit from five surfaces — the flat top and the four sides — while others have reflective sidewalls that limit emission to the top. The DOE report refers to the top emitters as having polymer sidewalls.

Generalizing, the authors said mid-power LEDs have essential matched high-power LEDs in reliability. It was only a few years ago when we ran a technical feature indicating just the opposite. The report said materials improvement has bolstered mid-power reliability. We began to see that happen with what Lumileds twice called mid-power March announcements.

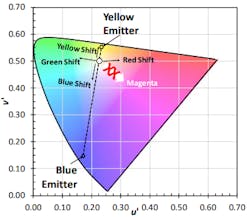

Turning to chromaticity shift, the story is quite different. Product developers can choose from LEDs in any single package type and achieve SSL systems with relatively good chromaticity uniformity compared to what has been common in the past. Yet the different LED types vary widely in how chromaticity shifts once it begins.

The authors of the DOE research refer to the phenomena as “chromaticity shift mode” (CSM). Mid-power LEDs tend to shift toward the blue region. High-power LEDs shift toward the yellow. COB devices from different manufacturers shift in a variety of directions. The authors did not offer this conclusion, but we would suggest that greatly varied COB architectures are the culprit. COB LEDs are built on aluminum and ceramic substrates. Some manufacturers use relatively large numbers of mid-power LEDs in such an array while others use far fewer high-power LEDs in an array.

CSP LEDs are also inconsistent, and the report breaks the situation down based on whether the device has the polymer sidewalls. Five-sided emitters exhibited either green or blue shift. CSPs with reflective sidewalls exhibited yellow or blue shift. Why does it matter? Well, a space with a mixture of luminaire types would generally also have a mixture of LED types in those luminaires. The mismatch could become very noticeable and significant over time.

The is a lot of great detail in the new report, far more than we can go into here. You can download the entire report in PDF form from the DOE website.

For up-to-the-minute LED and SSL updates, why not follow us on Twitter? You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn Company Page and our Facebook page.