Starting in the mid-2010s, broad-based LED upgrades to fluorescent lighting fixtures focused primarily on saving energy in the space rather than on improving lighting quality. A common strategy of installing tubular LED upgrades (TLEDs) offered significant energy efficiencies and extended lamp life compared to traditional fluorescent lighting. TLEDs were also easy to install, as they fit into existing fluorescent lamp sockets, and for day-to-day switched lighting they helped many buildings quickly meet energy reduction goals.

Now, facility managers are facing a new challenge — how to implement effective TLED retrofits in buildings that have more sophisticated control systems and dimming ballasts. They want to upgrade the fixtures without compromising existing lighting quality and control functionality. This is especially relevant in spaces like Class A offices with installed fluorescent T8 and T5 lamps, high-performance dimming ballasts, smart control systems, and advanced sequence of operations.

Directly replacing fluorescent bulbs with TLEDs on high-performance dimming ballasts is not advisable. Experience has shown that using traditional high-performance dimming ballasts with new TLED lamps often results in mixed or poor performance due to the bulbs’ different electrical characteristics. Problems like flicker, uneven dimming, and undesirably bright low-end light levels are common. Instead, when upgrading to TLEDs in architectural lighting applications and other high-end spaces, it is recommended to install dedicated LED drivers to replace the fluorescent ballasts. This is commonly referred to as a “UL Type C” retrofit.

This article focuses on the challenges and options associated with upgrades to TLEDs and drivers, while maintaining — or even upgrading — an existing dimming and lighting control system. (For an in-depth look at the issues surrounding other types of TLED upgrades, see “Tackle TLED tradeoffs to manage retrofit expectations” in the July 2017 issue of LEDs Magazine.)

Three steps to TLED upgrades with advanced controls

If end users are planning to upgrade legacy fluorescent lamps to LED lamps, they are generally doing so to improve lamp life, reduce energy use, and enhance overall light quality. With careful planning, all these goals can be achieved while minimizing installation cost, reducing downtime, maintaining (or even improving) the lighting system performance, and ultimately delivering a better lighting experience to space occupants.

Step 1: Understand the existing control system. Before starting any upgrade project, it’s important to first understand what’s currently in place. What are the characteristics of the current lighting control system, and do they meet the present needs? An LED lamp and ballast-to-driver upgrade can often work with your current control system, but this may be an opportune time to consider whether the existing system has all the features currently needed, or for the foreseeable future. Start any upgrade by understanding the control type that is currently installed. Most of today’s fluorescent dimming ballasts use one of four control types: 2-wire analog phase control, 3-wire analog phase control, 0–10V control, or digital control.

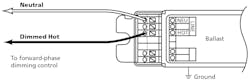

Two-wire controlled ballasts are frequently used in simple 120V control applications where existing wire was already present. This control setup typically offers dimming to 5% or 10% light at low end. The two-wire method uses the same wiring used for non-dimmable ballasts, and therefore provides an easy control upgrade opportunity. Two-wire controlled ballasts have two wires between the dimmer control and the ballast: Dimmed Hot and Neutral (Fig. 1). This control method has been widely used by major ballast manufacturers such as Lutron (Tu-Wire ballasts), Signify’s Philips brand (Advance Mark 10 ballasts), and others.

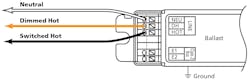

Three-wire controlled ballasts have been used widely in commercial installations for decades, as they allow for large numbers of 120V or 277V dimming ballasts to be used without adverse effects on power line quality. They are also capable of dimming to light levels as low as 1% at the low end. With this control scheme, three wires run from the control to the ballast: Hot (provides on/off power to the load), usually red or black colored wire; Dimmed Hot (provides a line voltage phase-cut signal, but does not deliver power), usually orange colored wire; and Neutral (Fig. 2).

While the adoption of 0–10V has really taken off in recent years due to the proliferation of LEDs, there are many legacy 0–10V control systems operating with fluorescent ballasts. These systems utilize four control wires: two wires for providing switched power, and two additional control wires for providing an analog voltage from 0 to 10V, which tells the ballast the desired light level. Most dimming ballast manufacturers have also made 0–10V ballasts, including Lutron (TVE ballasts), Signify/Philips (Advance Mark 7 ballasts), and others.

As the newest control protocol, digital control (EcoSystem or DALI — Digital Addressable Lighting Interface) offers the highest dimming performance and the greatest system flexibility. It is an excellent choice for applications that need deep dimming as well as the ability to easily make adjustments in response to changing building needs and take greatest advantage of integration with other control systems. Buildings with installed digital controls typically have the greatest interest in maintaining control capabilities as part of a TLED upgrade.

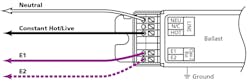

Digitally-controlled ballasts utilize four

wires for power and control: a two-wire digital

communications bus (for example, E1

and E2 wires, often purple-colored) connected

to multiple ballasts (up to 64), and

Constant-Hot (unswitched) power on a separate

pair of line-voltage wires directly from

a circuit breaker panel (Fig. 3).

With most digital controls, power and digital link can be run separately or in the same conduit, and the wiring is topology free and polarity insensitive. Digital ballasts and drivers are used to create flexible, digitally-controlled lighting systems that are capable of being rezoned without any wiring changes and allow dimming to light levels as low as 0.1% at the low end (Fig. 4). Digitally-controlled ballasts are available from all major ballast manufacturers.

Step 2: Understand the existing lamps and ballasts. Once you have confirmed the existing control system, take stock of the types of ballasts and lamps you have. There are a wide variety of ballasts, lamp types, and lamp quantities in your fixtures. It’s often easiest to start with the ballast label — this can help clarify the control type the ballast supports and the expected dimming performance (for example, is the low-end light level 10%, 5%, or 1%?). Low-end light level is an important factor in how well the lighting meets the needs of a given space or task. Conference rooms and training spaces often require deep dimming, while atriums and public spaces may not.

To upgrade fixtures to TLEDs, the ideal situation allows the existing control system to remain untouched, the dimming performance to be unaffected (or improved), and the existing quality and quantity of light to be maintained (or increased). If the right TLED retrofit is chosen, these goals can be reached; however, some adjustments to the internal workings of the fixture may change. For example, a 3-lamp fluorescent fixture may be able to be reduced to a 2-lamp TLED fixture, or a multi-lamp fixture with one ballast may require two LED drivers.

Choosing the right LED driver is critical to ensuring compatibility with both the existing control system and expected dimming performance. The driver manufacturer’s website, online reference tools, application notes, and whitepapers are useful references. Lutron, for example, recently published an application note that helps identify characteristics of legacy installed ballasts, provides expected performance information, and recommends a compatible LED driver family to maintain performance and control compatibility. (Note: The link will download a PDF.)

Retrofit UL Type C TLED lamp and driver kits are available from multiple manufacturers, allowing you to match the shapes and lengths of your existing fluorescent lamps, as well as the control type in many cases. Purchasing the TLED upgrade as a driver-plus-lamp kit ensures the driver and the lamp have been tested together and are confirmed to be compatible. Work with the kit manufacturer to ensure the replacement is suitable for your specific installation, taking into consideration desired dimming performance, control system compatibility, and even environmental conditions such as temperature (especially in unusual applications such as gymnasiums or other high-bay spaces).

For example, the Remphos brand from Light Efficient Design offers a selection of TLED lamps for replacing fluorescents, including T8, T5 HO, and T5 HE in most common lengths; PLL/BIAX; and pin-based CFL with a variety of different driver options and control types, including EcoSystem, 2-wire, and 3-wire controls. And GE Lighting has a UL Type C TLED solution, available in T8 and T5 2-ft (0.61 m) and 4-ft (1.22 m) lengths, multiple color temperatures, and various lumen outputs. The lamps are compatible with a wide variety of control types, including EcoSystem, 2-wire, and 3-wire controls.

Additional manufacturers offer LED retrofit kits. These are solutions for retrofitting existing fluorescent fixtures with LEDs using methods other than TLEDs. LED retrofit kits may involve installing a subplate within the fixture or employing other methods such as adhesive-backed light strips. In some cases, such as when the current optics, aesthetics, or mechanical characteristics of the fixture do not lend themselves to effective TLED usage, it may make sense to completely replace the existing fluorescent fixture with a new LED fixture. Examples of all these solutions can be found at www.lutron.com/findafixture.

Step 3: Consider potential upgrades. As part of an LED lighting upgrade, where each fixture will be modified as part of the work, it’s worth considering whether the existing lighting control system is up to the modern needs of the space. It may make sense to perform a TLED lighting upgrade and to also retrofit the existing wired control solution with a wirelessly-controlled system at the same time in the following situations:

- When the control type of the desired LED driver or TLED kit is not compatible with the available existing electrical wiring or control system

- When a code compliance requirement for occupancy/vacancy sensors and/or daylight sensors needs to be addressed, which cannot be accommodated by the existing control system

- When the needs of the space have changed or outgrown the capabilities of the existing control system, such as in a space that needs to be split into more granular control zones

Prepare to go wireless

If you are considering a wireless control upgrade, there are three methods for approaching it. While all three require investment in a new control system, each can be installed using existing electrical wiring while providing enhanced system performance and communication with wireless fixture controls. The result is better performance without all the cost of completely replacing a wired system. Each example requires a Constant-Hot power feed to the fixture; no additional wires need to be run.

Use a TLED kit with a digital driver and wireless control. This option uses a digital driver (EcoSystem or DALI) controlled with a wireless digital control mounted on a knockout on the outside of the existing fixture. Installation requires access to the top or side of the fixture or a nearby junction box to mount the control. A wireless digital control solution adds flexibility and reduces risk by making it easier to rezone and readdress fixtures using an app or centralized control protocol as space usage changes over time.

Use a TLED kit with a 0–10V driver and control. Option 2 allows a 0–10V LED driver to be controlled with a wireless 0–10V control that can be mounted on a knockout on the outside of the fixture, and, like the digital solution, requires access to the top or side of the fixture, or a nearby junction box. Dimming performance is less predictable with 0–10V retrofits, but it is a good option for meeting energy goals and providing elements of personal control to space occupants. If existing 0–10V wires are present between fixtures for the ballasts, this solution could also allow larger zones to be split into smaller zones.

Use a TLED with a digital driver and an “in-fixture” controller. Some fixture retrofit kits are available with integral wireless controls, making an upgrade to LED and wireless very simple. One example of such a solution is Lutron’s Integral “In-Fixture” Controller, which allows wireless control of EcoSystem and DALI-compatible drivers; similar wireless in-fixture solutions are available from other manufacturers (Fig. 5). Often, these types of controls are not designed for field installation, so this option is most likely to be feasible only if there are plans to use an LED Retrofit Kit that offers these options natively.

The key to success

TLED retrofits can effectively help reduce electricity use and enhance control performance in a wide variety of situations where fluorescent lamps and ballasts are still being used, including spaces that utilize dimming and sophisticated lighting control systems.

When approaching these projects, however, it is important to understand the control system being used, the lamp type being replaced, the specifics of the fixture, and the long-term control needs of the space. Ensuring these issues are addressed during the planning stages of an upgrade project will enhance the satisfaction of the occupants and help meet the goals of the building owners for years to come.

Get to know our expert

ETHAN BIERY is systems sales engineering leader at Lutron Electronics. Biery has nearly 20 years of experience with Lutron, and has been an active advocate for the increased adoption and performance of LED dimming and control. He has contributed technical articles and viewpoints to associations and publications including LEDs Magazine. Biery continues to pursue advancement of the LED and solid-state lighting and controls sectors via educational presentations, whitepapers, and standards development through organizations such as USNC and NEMA.

For up-to-the-minute LED and SSL updates, why not follow us on Twitter? You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn Company Page and our Facebook page.