INDUSTRY INSIGHTS | How AI facilitates indoor agriculture efficiencies

Modern greenhouse growers require operational flexibility to address market factors such as the growing demand for local food, labor shortages, and expenses related to energy and fertilizer.

On a wider scale, climate change presents multiple challenges through unpredictable weather, heat waves, pests, and diseases. Many greenhouse technologies have rapidly advanced to address such concerns through sophisticated environmental controls, energy screens, cogeneration, sensors, and imaging technologies. However, horticultural lighting has lagged behind. The current market-dominant lighting systems provide growers little flexibility for evolving conditions once installed, thus embedding limitations.

By harnessing artificial intelligence (AI), horticultural lighting suppliers can challenge this paradigm, providing smart LED solutions that are modular, resilient, and future-proof. Systems leveraging AI, such as Sollum’s SUN as a Service (SUNaaS), allow growers to adapt to changes such as introducing new crops, increasing yield and quality, environmental conditions, resource constraints, and business development objectives.

AI expands operational capabilities

By Sollum’s definition, AI integrates cutting-edge technologies and advanced algorithms to optimize and elevate various aspects of lighting systems and services. Machine learning and data analysis techniques can automate processes, enhance energy efficiency, and deliver enriched lighting scenarios.

Fine-tuning a lighting strategy according to cultivar is essential to greenhouse farming, as light responses are notoriously cultivar specific. For example, some lettuce cultivars grow best with a daily light integral of 16–17 mol/m2/day, while others can handle 20 mol/m2/day.

At its essence, an intelligent horticultural system learns, adapts, and provides actionable suggestions to growers. Truly smart lighting systems can dynamically adjust light intensity and spectrum by accounting for environmental factors, user objectives, and specific crop requirements. By changing the light spectrum and intensity, growers can manipulate and optimize crop development characteristics including pigments, secondary metabolites, flavor profile, aroma, and disease resistance. AI-supported lighting systems interact with their surroundings, minimizing stress on plants while offering personalized and responsive illumination that meets their needs.

AI algorithms analyze data obtained via daylight, moisture, and other environmental sensors integrated with greenhouse management systems to optimize lighting usage. By accurately measuring the amount of natural light available, an intelligent lighting system can automatically adjust lighting levels, resulting in energy savings and cost reduction. Moreover, AI algorithms learn patterns and user preferences gradually, enabling the lighting system to anticipate and adjust to the evolving needs of greenhouse operators.

AI also improves predictive maintenance. The system can identify potential faults or issues from the input provided by temperature sensors, power usage monitors, and performance indicators. This proactive approach enables growers to schedule maintenance activities that minimize downtime and enhance the overall reliability of their greenhouse systems.

In the near future, AI will support the creation of smart control interfaces for lighting systems. The emergence of natural language processing technologies holds great potential. In the horticultural sector, it could allow users to interact directly with the lighting system, making it simpler to adjust lighting settings or create personalized lighting configurations. This user-friendly interface will play a crucial role in improving the overall experience and making lighting controls more accessible.

Achieving an agile response

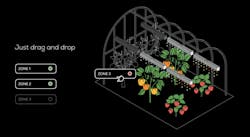

Hardware and software integration allows growers to achieve precise control over greenhouse environments, empowers users to establish unlimited zones, and supports efficient multicrop and/or genetics management. By defining specific light recipes and treatment parameters for each zone, growers can tailor conditions to suit the unique requirements of different crops or genetic varieties.

Sollum’s dynamic cloud-based ecosystem depends upon intelligent light fixtures that can operate autonomously, along with a network of advanced sensors to furnish operators and service providers with valuable feedback. Modularity is a key component, supported by independent, repeated entities that are combined to form a larger unit. These repeated entities can be added, removed, or changed without affecting the whole architecture, offering multizone lighting options (Fig. 1). The hardware setup is seamlessly integrated with a robust software platform that provides a user-friendly interface for configuration, data management, and monitoring.

Advanced software-integrated lighting systems can also monitor ambient light signatures in real time. External sensors continuously collect data on natural light’s intensity and spectral distribution, which is fed into the software, analyzed, and interpreted to provide accurate insights into the current lighting conditions. Real-time monitoring ensures the lighting system responds to changes in natural light levels, managing the electric light appropriately to maintain a consistently hospitable environment for crops.

In some cases, energy costs can constitute 50% of total greenhouse operational costs (Shen et al., 2018), and most of that proportion can be attributed to lighting (Watson et al., 2018).

Finally, software-integrated systems offer additional cost savings and lighting efficiencies. During load shedding or power interruptions, the software can suggest modifications to the lighting recipe to reduce energy consumption without compromising critical operations. (See “AI enables a synergistic approach to energy management” below.) Lighting systems that merely increase brightness to mimic clear-sky conditions will consume additional electricity. On the other hand, dynamically adjusting light intensity, selectively adjusting the photoperiod recipe to respond to utility constraints, and leveraging available natural light sources can accrue greater energy savings.

Accessible user-specific light recipes

An AI-enabled lighting system has a clear value proposition for growers only if they receive proper training and support to utilize its features. A team of agronomists and technical specialists should provide training and support, collaborating with growers to create optimal light recipes and ensure their production is on track toward success.

Figure 2 shows a light recipe example developed via dynamic lighting compensation. LED luminaires turn on before sunrise and recreate the full sunlight spectrum, perhaps including far red to promote shoot elongation during vegetative growth in crops. As the sun rises, more photosynthetically active radiation (PAR) and far-red light become available to plants, and the ratio of blue-to-red artificial light decreases. Responding in real time, the LED light intensity reduces, far red is deactivated, and the fixture’s blue:red wavelength ratio output increases. As the sun sets, the intensity of the LEDs increases, the spectrum shifts accordingly, and far red is reactivated.

This is only one possible recipe out of an existing repository. As each season unfolds, Sollum adjusts light recipes to align with each grower’s needs. Once refined, the custom recipes become proprietary and accessible only to the users for whom they were tailored.

Exploiting the advantages of AI with the modularity of 100% programmable dynamic LED grow light solutions gives growers the flexibility to optimize their production, including quality, yield, and shelf life, while saving time and money.

AI enables synergistic energy collaboration

As indoor agriculture plays an increasingly important role in global food security, optimizing greenhouse lighting systems for energy efficiency becomes imperative.

Besides environmental and economic costs, energy availability is also a limiting factor for greenhouse operation and development. Recent growth in greenhouse projects, the popularity of artificial lighting for greenhouses, and the desire for year-round production have strained local energy grids. Worldwide, greenhouses alone account for an estimated electricity equivalent of 244,640 million kWh (Katzin et al., 2021).

Dynamic, AI-driven lighting solutions create a partnership opportunity between greenhouse operators and utility providers. Imagine a scenario in which growers receive real-time notifications about impending load-shedding events, allowing them to fine-tune their energy-intensive processes and minimize the impact to operations while responding to utility needs.

Sollum specialists are working with utilities to further develop intelligent systems that optimize energy usage during peak periods to alleviate strain on the power grid while ensuring that growers’ production remains uninterrupted. An AI-enabled platform can allow utilities to seamlessly communicate energy availability, empowering growers to make informed decisions that balance productivity and energy conservation, such as enacting real-time dimming and dynamic spectral tuning. Preliminary research has shown these features reduce energy consumption by 20% over traditional LED systems.

The symbiotic relationship between growers and utilities holds immense promise. Horticultural systems providers can help both parties navigate the challenges of load shedding and transform them into opportunities for pioneering new load management techniques, reducing grid stress, and enhancing the overall stability of energy infrastructure. ♦

FRANCOIS ROY-MOIŞAN, co-founder and CTO at Sollum Technologies, has developed extensive expertise in photonics and electronics throughout his professional career, specifically in prototype development and digital acquisition systems. He also contributed to the research and development of infrared cameras for space. With a master’s degree in electrical engineering, Moişan has worked in SMEs and large companies and participated in research at INO, INRS, and ÉTS.

*Sollum Technologies develops horticultural lighting software and hardware solutions such as those described in this article.

Follow our LinkedIn page for our latest news updates, contributed articles, and commentary, and our Facebook page for events announcements and more. You can also find us on Twitter.

Francois Roy-Moişan

FRANCOIS ROY-MOIŞAN, co-founder and CTO at Sollum Technologies, has developed extensive expertise in photonics and electronics throughout his professional career, specifically in prototype development and digital acquisition systems. He also contributed to the research and development of infrared cameras for space. With a master’s degree in electrical engineering, Moişan has worked in SMEs and large companies and participated in research at INO, INRS, and ÉTS.