In high power LED applications such as architectural lighting and LCD backlighting, color accuracy is the most important electronic design consideration. The ideal solution to achieve this accuracy is to measure the wavelengths produced by the lighting system with a color sensor. Without this sensor additional challenges are created, requiring the lighting circuit to measure, control or calculate all of the parameters that affect the performance of the LED.

The ecosystem of a high power LED design presents unique challenges, as it requires expertise in widely variant areas. To accurately mix color the system must have adequate electronic, thermal and optical design elements. The electronic aspect will measure the forward voltage, current, and board temperature signals. The number of parameters affects the potential size and cost of the analog circuit itself, obviously a concern for engineers everywhere.

The thermal design is potentially the most overlooked, as LEDs do not radiate heat similar to an Edison lightbulb, but instead conduct it through the junction to the mount. The junction temperature therefore can fluctuate wildly if there is a lack of attention to the type of board connection, be it epoxy, grease or solder. The junction temperature affects the luminous flux and the dominant wavelength of the LED, both of which affect the mixed color generated by the overall system of LEDs. Finally, optical design knowledge is necessary to diffuse the output of each LED to create the appropriate color, necessary for there to be little variance between manufactured boards.

Color mixing is done by dimming each LED a calculated amount and diffusing the light generated by the lighting system. While working with these LEDs on the bench diffusing the light is extremely important, the intensity of the output may damage your eyes. Any engineer who remembers the birth of laser pointers will remember the spots that stayed in their vision for hours when the personal experiments in high school involved direct exposure to the beam. To solve this problem, it is recommended to radiate the LEDs into a simple diffusing material such as paper, a Styrofoam cup or the inside of a white box. Still, take care and avoid exposure to direct radiation.

Correlated color temperature or chromaticity coordinates

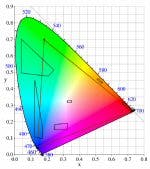

Chromaticity coordinates are a unit of measure which provides a set of (x, y) coordinates for each color in the visible spectrum; the 1931 CIE color chart, shown in figure 1, has become the de facto standard for specifying color in lighting designs. Correlated color temperature is a unit of measure that describes a color near the Planckian locus (black-body radiation curve) in the CIE color space.

The 1931 CIE color chart is shown in figure 1, color points are usually defined by picking an acceptable range of x and y values for each color. The CIE chart is useful for specifying color mix points in the project planning phase. For most applications red, green and blue (RGB) LEDs will be used to create a particular color point. Remember back to preschool and the first indoctrination into the magical world of fingerpaints, and the color mixing method becomes clear. Yellow plus Blue still makes Green.

The color temperature parameter is useful for specifying types of white light. The Planckian locus, shown in figure 1, runs right through the middle of the white region of the CIE chart and it is easier for the brain to process a number than a set of coordinates.

It is important to note that color temperature is somewhat unintuitive because “hotter” whites have a blue tint and “cool” whites are tinted towards yellow, orange or red. Still, the color temperature is converted to a chromaticity coordinate region for processing. In multicolored designs chromaticity coordinates from the 1931 CIE color chart are the preferred measure of performance and accuracy, as the level of complexity in working with multiple color temperature numbers for each LED gets unwieldy quickly.

Color gamut

An additional challenge for a designer is dealing with the separate LED bins from manufacturers. LEDs are binned by forward voltage, dominant wavelength and luminosity, and there can be large variances even within bins themselves. Also, there is no set bin specification for the LED marketplace, meaning that bins vary widely from manufacturer to manufacturer.

The ability to meet a color point is dependent on the bin shipped by the LED vendor; the LED bins can be plotted on the CIE color chart to determine if a targeted color-point resides in a valid region, this is known as the color gamut shown in figure 2. It is important to plot all of the possible bins to ensure that the targeted color point will be realizable no matter which bins are shipped by the vendor. If the targeted color point is outside of the valid region it is essential to the success of the project to either change the color point, make a deal with the vendor to only ship specific LED bins or add a fourth LED to increase the size of the gamut to meet the targeted color point.

An example of this is shown in figure 2. Six different sets of chromaticity coordinates are given:

Red – (.6875, .3010) (.6930, .3045) (.7150, .2750) (.7200, .2800)

Green – (.0250, .5100) (.0250, .7000) (.2000, .4100) (.2500, .5000)

Blue – (.1200, .1000) (.1300, .4300) (.1700, .1500) (.1700, .0750)

Yellow/Amber – (.5700, .4250) (.5850, .4075) (.5750, .4225) (.5875, .4100)

Violet/Purple – (.2550, .1750) (.2450, .1500) (.3200, .1800) (.3225, .1500)

White – (.3270, .3400) (3270, .3200) (3500, 3675) (.3500, 3300)

The set of four coordinates gives a box of allowable color gamut for the application. When the LEDs are plotted in the figure, it is seen that the Amber coordinate box is unreachable. In order to increase the size of the valid region, another LED has to be added, in this case an Amber LED.

Temperature concerns

As the temperature of the lighting system increases the performance of each LED deteriorates, as the luminous flux decreases and the dominant wavelength increases. To compensate for the degradation in the luminous flux, the LED has to be driven harder to account for the lost light output, which can result in a thermal runaway condition and eventual destruction of the LED. Since, as stated earlier, high power LEDs conduct heat through the junction, a rapid thermal runaway could introduce safety issues for consumer devices. Proper care must be taken to either shut the system down or to meet the color point at a safer intensity level. As the dominant wavelength increases the dimming values for each LED need to be recalculated to ensure that the targeted color point is still being met at the elevated temperature.

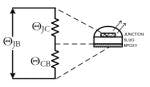

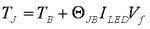

Because the LED temperature changes relatively slowly, the measurements to determine the temperature can be thought of as nearly static. This affords the designer greater flexibility in the way measurements are taken. Reading junction temperature directly is not possible, because there is thermal impedance from the junction to the slug and from the slug to the board as shown in figure 3.

How is it done?

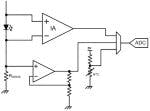

Now there are three signals to be multiplexed to the ADC (figure 6) and the circuit is a third of the size as the circuit in figure 4.

Programmable analog

The promise of programmable analog chips is that designers will have the flexibility to reconfigure analog circuits on the fly. This in-system reconfigurability is useful for a variety of applications, such as LED color mixing, where a dynamic solution makes the circuit in figure 6 simple to implement, as shown in figure 7.

Additionally, the reconfigurable analog enables further reduction in circuit size by adding the ability to change the gain, amplifier configuration, filter settings and ADC settings. For example, look at figure 7; in one configuration PGA1 acts as a current sense amplifier and in another configuration it acts as an input stage for the instrumentation amplifier measuring the differential LED forward voltage. The configurations are controlled by an on chip microcontroller; the microcontroller processes the ADC data, controls the LED drive and changes the analog configuration.

ASICs provide some of the same flexibility of programmable analog ICs because the circuit in figure 6 can be pulled into the IC. The obvious advantage to ASIC design is that the designer gets what they want. At the start of the project the system requirements, and the requirements for the ASIC, are defined. Ideally, the requirements at the beginning of the project are the same as the requirements at the end of the project. Unfortunately, project requirements rarely remain consistent from beginning to end, engineers blame this as “marketing”. When these changes appear, ASIC development must be modified or completely redesigned, which creates a significant resource and money issue for companies.

The advantage of programmable analog ICs over ASICs is that the chip can be reprogrammed as the project requirements change. If an LED design begins as RGB, but needs to move to RGBW, a programmable IC adds another signal input to the MUX at the front end, configures the gain appropriately from the op amp, adds an internal filter, and uses the internal ADC, all without affecting the RGB design already in place. In practice, the same chip selected at the beginning of a project still works at the end of a project, and most manufacturers create programmable ICs to be forwards-backwards compatible if more memory or internal resources are needed.

The Cypress PSoC mixed-signal controller has a unique architecture that allows the digital and analog resources to be reconfigured for different analog input signals. In this case the analog input circuit in figure 7 works as both an instrumentation amplifier, for measuring the LED forward voltage, and as a non-inverting amplifier for amplifying the voltage on the current sense resistors and NTC thermistor. The amplifier changes from an instrumentation amplifier (INSAMP) (shown) to a non-inverting amplifier (PGA) (not shown) by changing the connection point of the internal resistor string. In the INSAMP configuration, the bottom of each amplifier's resistor string are tied to each other. In the PGA configuration the bottom of the resistor strings are tied to VSS.

PSoC analog circuitry has the additional functionality of a configurable analog multiplexer. The PSoC multiplexer can be configured as 8:1 multiplexer for measuring as many as eight single-ended inputs, such as thermistors. The multiplexer can also be configured as two 4:1 multiplexers for measuring up to 4 differential signals. In this particular application, there are three differential signal (LED forward voltages) and one single-ended signal (thermistor) are controlled with the same multiplexer. In this case the forward voltage and current of three different LEDs and a thermistor are measured.

Conclusion

The high power LED marketplace is ripe for engineers of all stripes to originate new ideas and applications, as it moves towards being a ten billion dollar market in the next few years. The ability to create rich colors across the visible spectrum with a solution that has a longer life and greater efficiency is opening up opportunities from lightbulb vendors to LCD TV manufacturers. Designers attempting to enter this market would be well served to understand the advantages programmable ICs offer to make their jobs that much easier. From cutting down the bill of materials using the internal front end mixes to dynamically reconfiguring the analog circuit for each individual signal, programmable ICs can provide a cheap, accurate solution for color mixing applications.