The CRI of the module at 2700K is 96 (Ra). PhotonStar LED says this makes it a long-life and energy-efficient replacement for today’s incandescent and halogen sources, offering near-identical illumination and color quality but with no radiated heat or UV. The LED light engine will be scalable and the first, entry-level luminaire product will provide an output of about 500 lm.

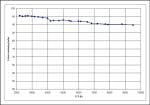

The ChromaWhite Luminaire will offer user-changeable white light from very warm white (2500K) to daylight (5500K) to over 10,000K, with a CRI (Ra) as high as 96 depending on the selected color temperature. A graph of the CRI vs. white color temperature from one of the prototypes luminaires is shown opposite.

Color mixing

Whilst the idea of color-mixing LEDs to produce white is not new, the PhotonStar ChromaWhite intelligent luminaire can simultaneously achieve high CRI and high efficiency. This is not possible with typical red, green and blue LED modules, which when mixed together to form white light typically have a CRI between 30-60 and low efficiency (typically 30 lm/W with today’s modules).

The poor CRI of the RGB color-mix LED solutions means they are good for decorative and architectural applications, but for illumination the reproduction of colors remains poor and the color quality factor (typically denoted as R96a) remains low. This makes such light sources unsuitable for general illumination.

Majd Zoorob, founder and chief technical officer of PhotonStar LED Ltd, says “the combination of excellent thermal management and proprietary optical color mixing technology enables the ChromaWhite Intelligent Luminaire to generate a stable, user-definable color temperature with none of the chromaticity-related binning yield traditionally associated with blue LED chip and yellow phosphor technology. This has big savings on the costs associated with LED module manufacture as well as offering one of the highest quality lighting sources available.”

“In addition,” continued Zoorob, “with a suitable control interface lighting, color effects normally associated with RGB systems can be achieved from the same ChromaWhite Luminiare.”

Thermal management

Existing fixed-color high power LED modules typically have thermal resistances between 6 and 8 K/W. In real applications, such as a luminaire with 4 modules driven at a recommended 700mA, the junction temperature can be as high at 85°C even though a low thermal resistance heat sink is only warm to the touch. This is not ideal and limits the lifetime to about 50,000 hours.

The PhotonStar LED module has a thermal resistance from LED junction to inside the heat-sink of just 0.8 K/W, opening up the way to drive modules at even higher power while still maintaining significantly lower junction temperatures. This results in longer life, higher efficiency and more flexible operation. In turn, this will allow next-generation luminaires to operate at ambient temperatures as high as 75°C and still maintain excellent lifetimes.

‘This is a great first result for our prototype luminaire but lots of work lies ahead to prove these modules are reliable enough to integrate them in our world class Luminaire products early next year’ says James Mckenzie, CEO of PhotonStar LED Ltd.

The company made its product debut at ARC 08 launching the first of its Performance Ecolighting products, the CeilingStar5-IC, a downlighter for use in fully insulated ceilings.