In germicidal ultraviolet (GUV) applications, it is worth remembering that UV light is not like a germicidal gas that fills a space and kills everything. UV light only kills germs on exposed surfaces — on the table, not under the table, on the fabric, not in the fabric, and so on.

Ultraviolet radiation can be measured in situ with many commercially-available handheld UV radiometers. These instruments measure UV irradiance (typically in mW/cm2) in points. But such point measurements will not be of much help when planning new GUV installations in office spaces or hospitals, for example.

Until the introduction of plastics in healthcare settings and the availability of antibiotics and vaccines, GUV was commonly used to sterilize operating theaters and other rooms overnight. Recently, there has been a comeback in the use of whole-room UV-C-band (100–280 nm) exposure devices for healthcare premises, office spaces, and shops. The intention is to disinfect the air and accessible surfaces in the room.1

Consequently, it is imperative to apply certified methods for predicting the practical effects of GUV. In essence, proper data may be the difference between planning for effective elimination of bacteria and viruses and delivering a false sense of security.

Lethal lighting design?

For many reasons (possible photokeratitis, erythema, carcinogenesis, etc.), occupants should not be exposed to UV light in a space. But insufficient UV lighting design may be harmful, if not lethal, to occupants in other ways. Not knowing the exact UV irradiance applied to a surface means that germicidal effectiveness cannot be verified. Therefore, pathogens may survive UV treatment and still pose a threat to humans.

The good news is that UV lighting design is not as difficult as one might expect. In fact, a similar methodology to that used for planning visible illumination designs may be employed with just a few modifications.

No need for new planning software

The amount of UV light that is applied to a given surface can be investigated using more or less the same approach as with visible light. In the world of general illumination, there is no way around utilizing a 3-D representation of the light distribution — an IES or LDT file — as well as some spectral information (CCT, color coordinates, etc.). With this information, we are ready to simulate light in a real space. This method can also be applied to GUV product design and by using the same software solutions.

Viso Systems customer Christian Byriel, product specialist at UV Medico, points out, “Generally, we are happy with using the free DIALux software for estimating real-life germicidal potential. Further, the software graphics are great for illustrating this potential to our clients. However, we are dependent on proper UV 3-D measurement files as input to these simulations.”

As Byriel notes, the method is much the same, but some complexity is added: A 3-D UV light distribution file and the competency to calculate exposure time are required.

Getting the right UV light data

Some suppliers measure the distribution pattern of UV light sources with conventional goniophotometers — i.e., measurements limited to the visible part of the spectrum. This is feasible because most UV light sources also emit small amounts of visible light. By measuring the UV output in the peak angle with a handheld instrument, a 3-D UV light distribution can be calculated. However, this calculation is only correct if the UV light distribution is proportional to the distribution of visible light. Practical experience shows that in many cases this assumption is wrong.

Director of Viso Systems Christian Krause explains why: “UV light interacts very differently with internal luminaire materials and surfaces. Probably, only naked UV light sources will distribute UV light as indicated by their distribution of visual light.”

This is because short-wavelength light is more prone to being absorbed by many surfaces.2 As a result, UV light distributions may be very different from the related visible light distribution depending on the optical complexity on the luminaire. The absorption depends on UV light interacting with diffusers, painted surfaces, reflectors, and lenses.

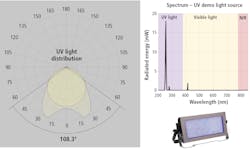

To add to this problem, it may not be enough to replace the photometer sensor with a UV sensor that captures the total UV radiation as a lump sum — e.g., from 200 to 400 nm (in parallel to lumen values that are captured as a v(λ)-corrected total between 380 and 780 nm). UV light is not solely UV light. It must be broken down in sub-spectra — traditionally, UV-A, UV-B, and UV-C bands. And even more detail is needed now. For instance, recent scientific literature3 points to an interesting sub-spectrum just around 222 nm (also often called far UV or far UV-C) for germicidal irradiation, which is not harmful to human skin. Consequently, evaluation of UV germicidal effects demands 3-D UV light distribution combined with angular spectral information as shown in Fig. 1.

No way around goniospectrometry

We can conclude that, for simulation purposes, both the UV light spectrum and radiance must be measured in all angles to represent a true UV light distribution. In other words, a goniometer fitted with a spectrometer is the solution to capture angular spectral distributions — i.e., a goniospectrometer. Many small goniospectrometers exist in the market. Most of these systems are intended for measuring prisms and small light sources of 1–5 in. diameter. But this will not serve for contemporary UV light fixtures that are perhaps 6–7 ft long.

The ADJ Group senior project specialist Red Walter explains the advantages of using a goniospectrometer system. “We’ve used this technology in our in-house lab to provide Acclaim, ADJ, and Elation customers accurate photometric reports for over five years. UVGI [UV germicidal irradiation] calculations require a measurement precision that handheld or lesser expensive instruments do not provide. The addition of the UV-VIS sensor to our lab allowed us to quickly test and verify the Absolve Solutions offerings before sending them out for third-party lab certifications. We can also provide a specific IES file for industry professionals to design a germicidal solution for their clients using DIALux or similar rendering software. Most UVGI fixture reports use the entirety of a fixture’s energy to determine the irradiation power when in reality, pathogens respond to specific wavelengths differently. Being able to isolate specific wavelengths like 254 nm from the entire UV range allows us to provide the most accurate data for the detailed calculations that are required for pathogen inactivation.”

Simulating germicidal effects of UV light

In many ways, simulating UV light in real spaces is like simulating visual light. The same types of measurements are needed and even well-known software as DIALux and Relux can be used.

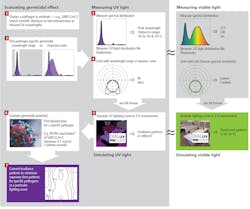

Figure 2 shows the steps needed – including the steps that needs to be added to evaluate germicidal potential of UV irradiance.

Step 1: Choose a pathogen to evaluate. Viruses, bacteria, and fungi react very differently to UV exposure. Traditionally, E. coli has been used as a broadly accepted indicator of bacterial activity and especially fecal pollution. During the last year, a number of scientific studies have worked with the properties of the SARS-CoV-2 virus and also the potential doses needed to deactivate this virus (LEDs Magazine has covered several examples, including a Boston lab study). For instance, a group of Italian scientists reached the conclusion that a 254-nm UV light source and 3.7 mJ/cm2 dose provided a 3-log reduction — that is 99.9% inactivation — of SARS-CoV-2 (the virus responsible for COVID-19).4

Step 2: Measure spectral distribution and 3-D radiation distribution of the specific light source. This step is similar to measuring the light distribution and spectral qualities of visible light sources. With a goniospectrometer, both spectral qualities and the 3-D distribution are captured simultaneously.

Step 3: Find spectral sensitivity for the specific pathogen. As we have established, many UV light sources also emit visible light. However, the measurement results should only include wavelengths that have a germicidal effect. As pathogens react differently to various wavelengths, this narrowed-down result should be adapted to the pathogen under study. Some germicidal effects are defined in a certain wavelength range — e.g., 254 nm ±10 nm. Other studies have resulted in more detailed spectral sensitivity curves that define the germicidal effect as a function of wavelength. This is paralleled by the v(λ) curve that we use in the world of visible light to describe human spectral sensitivity.

Step 4: Apply spectral limitations to the radiation results. Not all wavelengths count, and only germicidal wavelengths should influence our simulations. Hence, apply a limiting wavelength interval — e.g., 254 nm ±10 nm — or apply a pathogen-specific spectral sensitivity curve.

Next, export the results to a traditional .ies (or .ldt) light distribution file. As .ies/.ldt files are designed for visible light, all units are assumed to be in photometric units. The idea of exporting UV light (in radiometric units) to this format essentially violates the formats. Nevertheless, if the user remembers that all values are correct but units are wrong, both light distribution files and subsequent simulations can use traditional data formats and software. Thus, values in lumens must be interpreted as watts, and values in candelas (cd) must be interpreted as in watts/steradian (W/sr).

Step 5: Simulate UV lighting scene. With the 3-D UV light distribution file generated under step 4, it is possible to build a UV radiation scene for a specific environment. This is paralleled by how we simulate visible light in spaces. We may use the same simulation software, such as Relux and DIALux, while again remembering that output values are right but units are wrong: Lumens must be interpreted as watts and values in lux must be interpreted as in W/m2.

When building the 3-D model of the scene, we must take care to apply realistic reflectances to surfaces. As previously mentioned, this is important as UV light is easily absorbed and must be prevented from bouncing off surfaces, thus falsely contributing to UV irradiance on target surfaces. There are not many studies describing UV absorption in surface types normally present in office environments, for example. Normally, software as DIALux and Relux would prompt surface reflectances such ceiling/walls/floor as 0.7/0.5/0.2, and much furniture in simulation is white. This must be changed. A good starting point is setting all surface reflectances to 0.1. A little more detailed information can be found in the referenced study.2

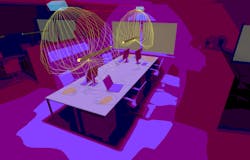

The output of such a simulation can involve several UV luminaires and may look like Fig. 3. As with simulating visible light, it is natural to include specific calculation objects in areas of interest. In an office space, it might be interesting to investigate the UV irradiance on the desks, drawer fronts, and keyboards.

A false-color rendition of the irradiance offers an intuitive way of understanding the germicidal potential as highlights and deep shadows clearly show.

Step 6: Evaluate germicidal potential. In step 5, we found specific UV irradiance (W/m2) patterns in a chosen 3-D environment. Next, we want to establish how a specific pathogen reacts to this irradiation. Again, consult scientific studies found under step 1 and find specific dose — e.g., 3.7 mJ/cm2 for 99.9% inactivation.

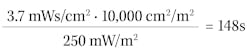

Step 7: How long should UV lamps be on? With this input, we can convert our irradiance patterns and values to exposure time. For example, if the average irradiance on the desk is 250 mW/m2 and we want to inactivate on average 99.9% of the selected pathogen with a dose of 3.7 mJ/cm2, the lamps need to be on for 148 seconds or approximately 2.5 minutes:

With this kind of conversion, a complete set of iso-irradiance curves can be converted into iso-exposure time curves. The result can be used to inform a space design plan and is useful for communicating the results to specifiers and clients.

It is worth noting that this result is valid for this particular pathogen only, and in this specific lighting scene only. Inactivation results should always be verified with practical measurements and preferably tests according to standards such as ASTM E2180 – 2018 or ASTM E3135-2018.

REFERENCES

1. Commission Internationale de l’Eclairage (CIE; International Commission on Illumination), “CIE Position Statement on Ultraviolet (UV) Radiation to Manage the Risk of COVID-19 Transmission,” retrieved from https://cie.co.at/ (May 12, 2020).

2. J.T. Turner et al., “Ultraviolet Radiation Albedo and Reflectance in Review: The Influence to Ultraviolet Exposure in Occupational Settings,” Int J Environ Res Public Health (2018).

3. M. Buonanno et al., “Germicidal Efficacy and Mammalian Skin Safety of 222-nm UV Light,” Radiation Res, 187, 4, 483–491 (2017).

4. M. Biasin et al., “UV-C irradiation is highly effective in inactivating and inhibiting SARS-CoV-2 replication,” Scientific Reports, 11, Article 6260 (March 18, 2021).

Get to know our expert

ANNE BAY, technical sales director of Viso Systems, graduated in civil engineering in 1994 and has worked with lighting since 2001. She has participated for many years in Danish and international standardization as a member of the Zhaga Consortium and by chairing the Danish national CIE committee as well as the Danish CE TC169 mirror committee. As director of Danish IES, Bay has been heavily involved with lighting lectures and education and several research projects. She was formerly employed with Louis Poulsen Lighting for 10 years and has been employed with Viso Systems for 1.5 years.

*Updated Sept. 2, 2021 9:00 AM for correction to in-text reference number.

Enjoyed this article? Visit our digital magazine for more like this >>