Although efficiency at this level or above has been achieved previously, the color values of OLEDs have not been within the acceptable band for color coordinates around the Planck curve.

According to Osram, the color coordinates of the white OLED were (0.43, 0,42). The active area of the lab device was roughly 2 cm2. The light output was at a low level, but when the technology is scaled up to larger sizes, in the future, the brightness is likely to be between 1000 and 5000 cd/m2 (which would correspond very roughly to 3000 to 15000 lumens for a one-meter-square OLED).

By developing a white OLED with a high light yield, the two companies claim to have completed a major step on the way towards commercial OLED lighting. BASF and Osram are conducting research together within the framework of the “OLEDs for Applications on the Lighting Market” (OPAL) project, which is sponsored as part of the OLED Initiative of the German Federal Ministry for Education and Research (BMBF).

The new OLEDs contain phosphorescent metal complexes as emitter materials and customized complementary materials, which ensure optimum constancy of the color temperatures. That means that, owing to the use of new materials, the diodes are very color-stable even when there are variations in luminous intensity. The challenge now is to optimize the life of these OLED tiles, especially by stabilizing the blue emitters.

BASF is dealing with the material side of the OLEDs and, within the framework of the OPAL project, is developing the optimum component structures in partnership with Philips and Osram. BASF reached an important milestone in OLED research a few years ago. White light from OLEDs can best be obtained by combining red, green and blue light. For a long time there was no efficient source for deep-blue light. In 2003 BASF researchers laid the foundation for a phosphorescent blue emitter by developing a new class of materials based on an iridium complex.

“Our aim is to develop stable blue phosphorescence emitters. Whilst the color coordinates and efficiencies of the new blue OLEDs are already outstanding, the service life still presents many challenges,” explains Elmar Kessenich, OLED project manager at BASF Future Business GmbH. “If we manage to produce deep-blue stable emitters, that will open up the way for us to make white OLED light tiles with a light yield of more than 100 lm/W.”

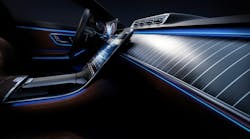

In future, OLEDs will be suitable for general lighting as flat sources of light – for offices or as decorative lighting in stores. And they not only offer the potential of being considerably more economical than conventional low-energy bulbs in terms of electricity consumption, but are also capable of being used in a variety of ways as flat, transparent and, in future also, flexible sources of light. They will provide completely new opportunities in terms of design and performance.

“The challenge now lies with the process engineers to apply these high efficiencies economically to large active areas,” says Karsten Heuser, OPAL Coordinator and Director OLED Lighting Technology at Osram Opto Semiconductors.