This article was published in the June 2011 issue of LEDs Magazine. View the Table of Contents and download the PDF file of the complete June 2011 issue.

+++++

Organic light-emitting diodes (OLEDs) now appear in a host of commercial electronics applications, most commonly in mobile phones, MP3 players, radio display panels in high-end cars, tablet PCs, and other consumer gadgets. An understanding of OLED technology has been with us for over half a century since researchers at Nancy-Université, France, first observed electroluminescence in organic materials in the 1950s. The affect was only apparent when relatively high voltages were applied to the materials.

The technology currently employed is attributed to W. Tan and A. VanSlyke, and was invented while these researchers were working at Kodak. The breakthrough was to produce a technology that operated at a low voltage and was relatively economical to manufacture. Today’s OLED construction is based upon a Kodak patent, and in November of 1997 Touhoku-Pioneer started the first mass-production of OLEDs, initially for car dashboard displays.

The drivers of OLED development in these display applications have been the need to reduce cost, weight and power consumption and to provide a better user experience through improved contrast and viewing angle. But what about OLEDs as general light sources? To understand the potential for OLEDs in lighting, let’s start with a little technical background.

How OLEDs work

OLEDs work by sandwiching a layer of organic material between two electrodes, an anode and a cathode, and depositing the whole thing onto a substrate, typically glass or plastic. When a low DC voltage is applied to the electrodes (positive to the anode, negative to the cathode), light is emitted when electrically-charged particles (holes and electrons) combine within the organic film. The characteristics and intensity of light emitted, and how it is extracted from the OLED assembly, determine its suitability for lighting applications.

One challenge for OLED development engineers has been how to create large panels. In general, the larger the panel that can be printed in one process, the lower the cost of the OLED light – there’s no need to fix a lot of individual panels together to achieve sufficient luminous intensity. Limitations in processes and materials determine how large a panel can be made. Another important consideration is the operating life of OLEDs. The higher the light output, the more limited the life of the device, so the most appropriate trade-off for each application has to be made.

OLEDs can be made in one of 3 ways, as shown in Fig. 2. Some leading manufacturers favor the multi-layer type on the left, and this is the simplest process. The tandem construction (right) is a little more complex but delivers more intense light output. It also allows larger formats to be created. Tandem construction is sometimes combined with the multi-layer structure.

Manufacturing processes for OLEDs seek to maximize light output and minimize pixel defects. To achieve these aims, in place of the dry process of vapor deposition of the layers that make up the OLED, Mitsubishi Chemical uses a wet process. This avoids defects in the OLED structure when microscopic particles of foreign material are encountered.

Desirable characteristics of OLEDs

As mentioned earlier, OLEDs need a large emission surface to be suitable for lighting applications so that they emit sufficient light to be useful. The quality of light, usually expressed as its color rendering index (CRI), is important in rendering colors accurately. Low-power operation, meaning high efficiency in converting electricity to light, is vital in a world focused on reducing energy consumption and CO₂ emissions. Also, in common with the requirements of OLED displays, OLED lights should not contain hazardous substances, need to be simple to operate, and must exhibit fast on/off response.

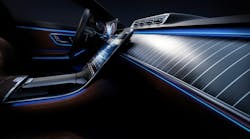

What’s available today? The latest dimmable, color-tunable and white-tone-tunable OLED panels are available in sizes up to about 140 x 140 mm, as shown in Fig. 1. They offer luminance of approximately 1000 cd/m2 at a color temperature of 3000K, enhanced by a light-extraction film on the luminous surface. Power consumption is about 2W. Panels are typically between 3.6 mm and 8.65 mm thick and have an operating life of over 8000 hours before the output falls to 70% of its initial value.

The white tone is tunable from 2700K – a typical warm-white figure – to about 6500K, equivalent to bright sunlight. Using a simple 3-channel electronic controller located on the back of each panel, the color can be tuned virtually instantaneously. Using this feature, together with dimming, the emotional impact of a lighting scheme based on OLED panels can be changed to reflect the mood required for the environment. For example, bright, white light may be desirable in the morning but more subdued, relaxing lighting with muted colors may be preferable towards the end of the day.

The technical protocols for RGB color tuning (DMX) and dimming (DALI) are well established, and low-cost controllers are widely available. Panels are easily calibrated and matched using the controllers to compensate for differences between panels cased by manufacturing process variations. In the near future, there is an expectation that the DALI protocol will be extended to include all aspects of color control, as well as dimming functions.

OLEDs are not yet ready to replace general indoor lighting, as has been suggested by some enthusiasts. However, they are now at the stage where they complement ambient lighting and task lighting to produce beautifully-balanced lighting schemes both in places of work and in the home. Their potential in retail environments and other public spaces is unlimited, and their low power requirements meet the demands of the most ardent environmentalists.