October 2005 - Download a PDF of the latest NeoPac product line (520 KB)

[The following article was written in June 2005. Recent news from NeoPac can be found in the Links at right.]

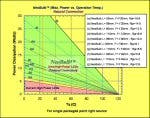

The key to the product is in its approach to thermal management. Since LEDs are temperature-sensitive devices, a rise in an LED’s junction temperature will decrease its light output, cause a shift in its color, and reduce its life. Thermal management represents one of the main challenges in improving the efficiency, durability and spectral characteristics of high-power LEDs.

High performance light engines

Neopac has achieved some very impressive results, for example from a light engine with a 66-mm-long heat pipe and 30-mm-diameter fins (similar in size to an A battery). The package's light source has a diameter of only 5.5 mm (i.e. an area of only 0.24 cm2), but can dissipate at least 5 W from a single 1 mm2 chip and still keep the junction temperature of the device at 103°C. The safe limit for high-power LEDs is usually quoted as 120°C. NeoPac estimates that its technology is capable of dissipating up to 30 W for natural convection, and 60 W for forced convection.

Dissipating 5 W of power in a 1mm2 chip corresponds to a heat flux of 500 W/cm2, which is 10 times the amount generated in a conventional microprocessor chip. Jeffrey Chen believes it is impossible for an LED chip to withstand such a huge power density using even the most advanced package technology currently in use.

New packaging approach"For ultra-high-power applications, the concept of LED packaging and assembly must be essentially changed,” says Jeffrey Chen. “For the NeoBulb approach, 14 patents have been filed internationally, from package and light engine level to bulb and luminaire levels. We are confident that NeoBulb will be the best solution for accelerating LEDs toward general lighting.”