Smart lighting and the IoT remain the big headliners at all lighting industry events, but MAURY WRIGHT explains that under the surface at LightFair International, it was the maturing enabling technology infrastructure that will hasten time-to-market for high-quality lighting and support for connectivity at the luminaire or SSL system level.

One can still be bedazzled walking the aisles at LightFair International (LFI), with beautiful products and vignettes aplenty and compelling smart lighting demonstrations ranging from indoor wayfinding to smart city applications. But that eye candy has been at LFI for several years. For the second consecutive year, however, it was the maturing LED and solid-state lighting (SSL) sectors, which have learned about product and system development from the electronics industry, that stood out. From LED component vendors to software developers, the compelling demonstrations were mostly in the area of building blocks and subsystems that will allow the industry to quickly develop luminaires with great light quality, easily support the Internet of Things (IoT) trend in luminaires and systems, and promptly add support for features such as tunable lighting that might just make for enjoyable ambience or perhaps will profoundly impact humanwellbeing.

What you will notice as you continue through this article is that the headline-grabbing developments such as the IoT are still important. The lighting industry must execute on these new applications for networked LED-based lighting to succeed long term. But the industry largely got ahead of itself with companies developing proprietary systems and pushing applications before their customers were ready. Now we are seeing more partnerships, some slight move toward standards, and the evolution of ecosystems that can make the IoT vision moreaffordable.

Meanwhile, the lighting specifiers and designers continue to ramp their expectations of light quality both in new products and over time in installed systems. Moreover, that specifier community wants support for new features such as tunable lighting. The enabling technologies we will discuss can support product and system development across the landscape of what specifiers might desire.

Tunable SSL

Let’s start with tunable lighting that, as we implied previously, can lead to human-centric lighting installations, or what might be called lighting for health and wellbeing. The tunability could instead be used for aesthetics. While the lighting-for-health science is still developing, it’s getting much simpler for SSL product developers to deliver products with variable CCT or variable spectral power distribution (SPD).

Lutron is making a major push into tunable lighting both in enabling technologies and in complete SSL systems. Not long before LFI, Lutron acquired Ketra — a startup company dedicated to tunable lighting for health and wellbeing including the fixtures and complex control system. We recently published a two-part article series on a Ketra residential installation. And Ketra occupied a major part of the Lutron LFI exhibit.

But Lutron is at heart a lighting controls specialist. And the company has taken its LED driver portfolio in the direction of tunable lighting. At LFI, the company announced the T-Series 2-channel driver and the companion T-Series ESN controller (Fig. 1). The driver allows luminaire manufacturers to easily develop tunable luminaires because the driver can separately control the intensity of two individual LED strings. And with such control, a luminaire can deliver light with variable intensity and CCT.

FIG. 1. The T-Series driver and ESN controller from Lutron simplify tunable luminaire designs and ensure a simple user interface once such products are installed.

Of course, the control side of the equation isn’t simple. But the T-Series ESN makes it so because specifiers can pair existing Lutron wall panels and smartphone controls with the T-Series ESN. Meanwhile, the T-Series ESN can connect to one driver/luminaire or a room full of them. So the combination can support tunability on a small room or full facility scale.

Lutron has also been among the leaders in precise dimming of LED luminaires via its Hi-Lume driver family. At LFI, the company announced the Hi-Lume Premier line for architectural lighting applications with dimming support down to 0.1% of full output and features such as soft on and fade to black. The driver includes support for the Lutron EcoSystem digital control interconnect that is DALI (digital addressable lighting interface) compliant.

LED light quality

Of course, great drivers would do the SSL sector little good if we didn’t also have a steady stream of high-quality packaged LEDs that are supporting advancement of light quality at the system level and enabling applications such as human-centric lighting. We did not see any new breakthroughs at LFI in terms of new packaged LED concepts; rather, we saw the industry begin to adopt new components we covered in the past year. Indeed, the product design cycle takes some time.

For example, Seoul Semiconductor was featuring its SunLike series of LEDs that were initially announced in June 2017. The violet emitter and three-phosphor mix deliver an SPD that mimics the sun in the human visual range.

At LFI, Seoul announced a list of SSL manufacturers that have brought SunLike-based lighting products to market and had many of those products on display (Fig. 2). The customer list included LED Luks, FLOS Architectural, LTS Licht & Leuchten GmbH, Yeelight, EssenziaLED LED Lighting, Ferrolight Design, and Alphabet Lighting (Ledra Brands). Seoul believes that SunLike will pervade general lighting, human-centric lighting, and horticultural lighting applications. At the earlier Light+Building event in Frankfurt, the company held a symposium on lighting for health.

FIG. 2. Seoul Semiconductor has signed on several lighting manufacturers to make products serving a range of applications with the SunLike LED family.

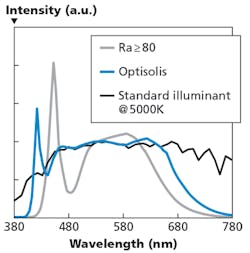

Meanwhile, Nichia announced its Optisolis LED line early this year with the components delivering CRI above 90, including for the 16 individual color samples. Unlike Seoul attempting to match SPD to the sun, Nichia is attempting to match the Optisolis SPD to that of the standard illuminant that is the basis of CRI and other metrics. Fig. 3 depicts the Optisolis SPD relative to the standard illuminant; you can see that Nichia minimized the blue peak and also the dip in energy that often occurs just after the blue peak in phosphor-converted white LEDs. We’d expect to see Optisolis-based products on the market soon. Also on a related subject, Nichia and Future Electronics presented a very compelling webcast recently on LED and SSL system reliability and lifetime.

FIG. 3. The Optisolis LED family from Nichia has an SPD that mimics that of the standard illuminant that is the basis of popular color metrics.

Osram Opto Semiconductors also demonstrated its new Pure LED family at LFI that’s intended for premium lighting applications such as in high-end retail. The Pure architecture emits only from the flat top surface of the LED and therefore offers extremely uniform beams and great color over angle. Those benefits are achieved via Osram’s UX:3 technology where the LED chip is lifted off the sapphire growth substrate at the backend of the production process and then is flipped and mounted to an opaque silicon substrate. You can get more detail in a video interview that we shot in the Osram Opto booth.

Moving along, Cree continues to offer what is probably the broadest packaged LED portfolio for lighting while developing parts for specific applications. At LFI, for example, the company demonstrated the XLamp XP-G3 S line that is a specialized version of the standard XP-G3 LED, with the “S” indicating improved sulfur resistance that would deliver better lifetime in outdoor and other harsh environments. The company also added LEDs to its High Current CMT chip-on-board (COB) LED family with the newest products matching the form factor of Citizen Electronics’ COB line.

Modular light engines

The enabling technology help for luminaire makers today goes far beyond LEDs. For several years, we have covered the development of modular light engines or printed-circuit boards (PCBs) that integrate LEDs in form factors that match the needs of popular luminaire form factors. That modular business has been called a Level 2 engagement. Modular products have always been available from third-party OEM suppliers and contract manufacturers, but Lumileds was one of the first LED manufacturers to embrace the concept back in 2014.

The Level 2 approach has increased in popularity as LED manufacturing has become more complex with mid-power and chip-scale package (CSP) components requiring automated surface-mount-capable assembly lines. And the modular approach significantly shortens market windows. Now manufacturers are adding features such as drivers and control circuits on board.

Still, the Level 2 engagements were generally limited to high-volume commodity luminaire types such as troffers and round downlights — but that’s changing as well. At LFI, for instance, Lumileds showed its modular light-guide line that the company added to its Matrix portfolio just before the exhibition, which is based on planar lightguides and enables elegant, sleek surface-mount fixtures in many shapes.

Lumileds refers to the Matrix additions as Integrated Light Guides. The planar technology has largely been used by large lighting companies including Eaton; Current, powered by GE; and Cree. For example, Cree entered the market back at LFI 2015 with the WaveMax family.

For the Matrix planar products, Lumileds sources the light guide that ensures uniform diffuse light and handles the mechanical design to couple the LED edge lighting to the optic. The company builds the modules to specification in terms of size and shape. A typical ceiling-mount round product tells a compelling story at only 4 mm thick while delivering 1500 lm (Fig. 4). The driver would be mounted in the ceiling with such a thin product.

FIG. 4. The newest modular light engine products in the Lumileds Matrix family include integrated edge-lit light guides and, as the side view of the product shows (left), an incredibly sleek form.

Level 2 products further afford manufacturers many options in driver circuitry today. For example, Seoul Semiconductor demonstrated AC-LED modules in square, circular, and linear form factors that integrate the Acrich AC driver technology. The company even has a version that has passed 4-kV surge testing, enabling usage in luminaires for 277V commercial applications, whereas most AC-LED technologies have targeted residentialapplications.

Enabling connected lighting

There were also quite a few modular or subsystem-level products demonstrated at LFI that can simplify the task of luminaire manufacturers developing smart lighting products. Consider TE Connectivity, a company that had such modular products for both outdoor and indoor SSL applications. The company has long supported smart functionality in street lights with its NEMA-compatible receptacle that would allow a luminaire maker to design the internal sensor, control, or connectivitycircuitry.

TE’s latest NEMA product further integrates a power supply and AC-power-switching relay, leaving less development work for the luminaire manufacturer. Development engineers would simply design a secondary PCB that mounts on the three posts that TE designed into its base (Fig. 5).

FIG. 5. TE Connectivity offers a NEMA module for street lights that can jumpstart smart-city developments and a sensor module for indoor-targeted luminaires.

For indoor, connected-SSL applications, TE offers the AmbiMateMS4 sensor module in PCB form. The PCB can easily be integrated into a luminaire and includes motion, temperature, humidity, and light sensors. The company further plans to add sound and gas (CO and CO2) sensing in future models.

Wireless sensors

Osram Digital Systems also demonstrated some interesting sensor technology in the SensiLUM product that is packaged in plastic and small enough to hold in your hand. The design includes some outward-facing sensors such as a PIR (passive infrared) sensor for occupancy in a space and a photo sensor for measuring ambient light. Those elements of the integrated multisensor product would be mounted on the luminaire in a way that the optic dome is exposed to the space. You can get a look at the sensor in a video interview we conducted at LFI.

The SensiLUM product can further communicate with a compatible driver via either a 0–10V connection or the Osram DEXAL (data exchange for advance lighting) interface — a non-proprietary bidirectional interface for intra-luminaire communications. The former would simply enable control of driver output, while the latter allows SensiLUM to report driver performance data such as power consumption, operating time, and thermal data.

To connect to a wireless central management system (CMS) such as the Osram Encelium IoT platform, the SensiLUM further integrates a ZigBee radio with a 150-ft range in line-of-sight conditions or 50-ft range through walls. Such a wireless link would allow the CMS to capture data such as occupancy, track energy usage, and control the luminaires remotely.

The Signify (formerly Philips Lighting) OEM business unit offers a similar architecture for smart luminaire designs. We covered the company’s SR (Sensor Ready) LED driver platform after demonstrations at LuxLive. Those drivers include a DALI-based intra-luminaire interface that can connect to sensor, connectivity, and control modules. At LFI, Signify demonstrated the Philips EasySense family of intelligent wireless sensors. Moreover, the company presented a recent webcast explaining its vision for enabling manufacturers to easily develop connected products.

Signify supports three scenarios for smart lighting: standalone fixtures with autonomous occupancy and daylighting controls, connected fixtures with no gateways or connection to a building management system (BMS), and connected fixtures with gateways and a BMS link. Furthermore, Signify demonstrated three EasySense products. The SNS200 integrates ZigBee support along with ambient light and occupancy sensors and could be used with or without a gateway. The SNS300 adds support for scheduling and demand response and generally would be used with a gateway and perhaps a BMS. The SNH200 matches the features of the SNS200 but has sensors designed for high-bay lighting, whereas the other two products are targeted at commercial office spaces (Fig. 6).

FIG. 6. Signify’s OEM unit exhibited Philips EasySense wireless sensors that communicate with the company’s SR (Sensor Ready) LED drivers for various connected lighting configurations.

The Signify sensors have one other interesting feature. The NFC (near-field communication) capability in smartphones can be used to configure or commission the sensors before luminaires are installed in the ceiling. Or once installed, the IR feature in smartphones can handle that task. For more information on the wireless commissioning problem being experienced across the industry, see our feature article from this issue on the topic.

Disinfection through SSL

At its roots, the smart lighting trend is about using the infrastructure being installed for necessary artificial light to accomplish other applications or services that may have little to do with our ability to see. And LEDs with easily tunable spectra can enable an ever-broadening set of new applications. One such application that was front and center at LFI was continuous disinfection through light in the violet and ultraviolet (UV) spectral ranges, with Hubbell Lighting and Current, powered by GE announcing such technology for the first time.

The concept of continuous disinfection is a compelling one, with pathogens lurking in spaces ranging from athletic locker rooms to food and beverage operations to healthcare-centric facilities — and more. Of course, you can use UV-C (ultraviolet C-band) energy to kill most any pathogen almost instantly. But that spectrum ranging from 100–280 nm will kill healthy cells as well and is dangerous to the human eye and other organs. Light at longer wavelengths takes much longer to kill bacteria but can be used with people present.

Vital Vio is one of the pioneers of the continuous disinfection application. That company uses violet energy that it says will kill 90% of the pathogens within a room over the course of one day. The violet energy targets specific molecules in bacterial cells and delivers an overload of oxygen that explodes the cells over time. The violet emission is mixed in with the broader-spectrum light that humans need to see, although some luminaires can power off the white light when no one is present in a space, leaving only the violet light to work its magic.

Vital Vio did not have an LFI exhibit, but the company has licensed its technology to other lighting manufacturers in addition to making some of its own products. Visa Lighting and Acuity Brands are two prominent licensees that were at LFI.

Still, it was the newcomers that made the application stand out. Hubbell Lighting announced that it signed a licensing agreement with the University of Strathclyde for access to the Glasgow, Scotland school’s continuous disinfection technology; the company demonstrated an early-stage prototype of a light engine at LFI. The violet technology being used by Hubbell is from the same intellectual property source that underlies products from Kenall Manufacturing. Kenall was the first to market with continuous-disinfection technology

and earlier this year won its second LEDs Magazine Sapphire Award for the Indigo-Clean ambient lighting product family.

John DiNardi, general manager and vice president of the Hubbell Lighting Components Business, said the two companies have licenses to service different markets. The Kenall license covers products sold into the healthcare market, according to DiNardi. Hubbell’s license states that it can supply the markets for “areas of congregation and the food and beverage industry.” DiNardi said areas of congregation would include places like locker rooms where bacteria is a dangerous problem in settings from youth to professional sports. Hubbell refers to the technology as High-Intensity Narrow-Spectrum (HINS) lighting.

Having licensed the technology, the Hubbell Lighting Components team will develop the light engines and technologies based on the intellectual property, such as the linear light engine demonstrated at LFI. Initially, the technology will come to market across the Hubbell Lighting brands in various luminaire form factors. There is also the possibility that Hubbell Lighting Components could eventually supply the enabling technology to other luminairemanufacturers.

Current, meanwhile, is the first company we have seen that plans to use UV energy for continuous disinfection. The company said the approach relies on UV-A emission. Generally, UV-A implies wavelengths ranging from 315–400 nm as we covered in an article on Strategies in Light presentations a few years back. The top of the UV-A range is just below the violet 405-nm area used in visible-light products. Current said its products will emit in the 300–380-nm range, and that it developed the intellectual property in house.

Current appears focused on healthcare-centric applications for the UV-A technology. The company said hospital readmissions due to healthcare-associated infections account for 28% of all readmissions. And the company expects the continuous-disinfection technology to positively impact that trend. The company could apply the technology in a variety of form factors.

Lighting products of note

Of course, we would be remiss if we failed to discuss any lighting products in an LFI exhibits story. And yes, there was plenty to see, although there seemed to be less in new luminaires that really wowed — or maybe we have just become jaded.

The LEDvance booth brought surprises. After stressing its presence in luminaires at Light+Building, the company offered a strong lamps message at LFI while still demonstrating numerous luminaires. The company especially highlighted the lamps being made in its St. Mary’s, PA and Versailles, KY factories (Fig. 7). The US-made products include A-line, globe, BR, and PAR lamps, and the company said its investment in automation has made manufacturing in the US economically attractive. LEDvance also gets high marks for the most creative party at LFI in Chicago with a Speakeasy venue to which a secret phrase was required for entry.

FIG. 7. LEDvance has German origins, Chinese ownership, and two US factories producing LED lamps on automated manufacturing lines.

We continue to struggle to understand the long-term plans for cousins LEDvance and Forest Lighting to operate as separate entities when both are essentially owned by Chinese conglomerate MLS. MLS had launched Forest into the US before acquiring a stake in LEDvance, and recently MLS assumed 100% ownership of LEDvance.

LEDvance remains a far larger and global company, but Forest is following a similar path in moving from being a lamps supplier to a company delivering luminaires and some more advanced technologies. At LFI, Forest demonstrated 2×2- and 2×4-ft troffer-style fixtures with flat-panel optics that also delivered tunable-white capability, and they can be controlled by a smartphone. In the lamps area, Forest demonstrated LED-based T8 retrofit lamps made from glass and said those products can be manufactured more economically than the more common plastic tubes.

New ideas in luminaires

New ideas in luminaires at LFI ranged from functional to elegant. In the functional category, consider the EZ Exit Lighting Kit from Fulham (Fig. 8). The unobtrusive fixtures hide in the seams of T-grid suspended ceilings with only an integrated test switch overtly evident. But the 24-in. model can deliver 1480 lm and the 48-in. model can deliver 2485 lm for 90 minutes after a power failure with Fulham’s HotSpot driver hiding in the ceiling.

FIG. 8. Fulham hides emergency lighting in the seams of T-grid ceilings, but the fixtures can deliver significant light output for 90 minutes after a power failure.

Moving to the elegant, Focal Point demonstrated its Skydome Edge product line. The round pendant luminaires utilize LED edge lighting for a uniform diverse beam. Moreover, different models can yield both direct and indirect lighting. Direct output ranges to 14,000 lm with diameters as large as 4 ft.

Now the most compelling demonstrations at a major event such as LFI are inevitably products that are in the concept stage. For example, we have been following QuarkStar for several years — a startup company focused on optics technology that can direct photons to where they are needed or desired while also reducing the size of luminaires and enabling new form factors.

QuarkStar had several demonstrations within the Avnet exhibit area including what it is calling the Edge-X technology. In one demo, a clear cylindrical optic descended from the ceiling and is virtually invisible in the off state. When powered on, the optic only produces light from the circular bottom surface. QuarkStar also showed a linear optic measuring 2 cm thick that emits a selection of beam patterns from the bottom edge. The company is licensing the technology to luminairemanufacturers.

Cree also got into the conceptual area in its booth this year with a cordoned-off demonstration room showcasing a technology the company called Arcadia. In the demonstration room, there were several square recessed panels in the ceiling that looked very much like skylights. The system appeared to generate lighting effects from behind the panels at the top of the recessed area through a planar optic. But the four sides of the recessed area also delivered light in some manner.

The effect of Arcadia was mimicking the experience of the sun in terms of intensity and CCT or SPD over a chronological period. The demonstration included a sense of compass direction in terms of the sun movement over the course of a day. The static photo does not quite do justice as a representation of the concept (Fig. 9). We have seen similar products before, including the CoeLux luminaires that were designed in Italy and have been deployed in a few instances such as in a Copenhagen restaurant that wants to project a California feel. But the technology has been veryexpensive.

FIG. 9. Cree’s dynamic, recessed Arcadia fixture represents a new era in indoor lighting that mimics the changing qualities of natural daylight while looking very much like a skylight in the ceiling.

Clearly, the technology involved in dynamically mimicking the sun has been very complex. But LFI would indicate that it may be realizable in more mainstream applications soon. Indeed, Cree doesn’t typically experiment with low-volume product concepts. In any case, it would be quite pleasant to live or work under Arcadia.