Based on LED or legacy sources, a DLP-based light-projection system offers many advantages over mechanical system such as GOBOs, and BRANDON SEISER and ZHONGYAN SHENG discuss all the functional elements that comprise such a system.

The ability to adjust the brightness, color, and light distribution of a lighting device is highly desirable in many applications. It enables new functionalities and adds dynamic effects to scenes based on specific activities. Digital micromirror devices (DMDs), a key component of Digital Light Processing (DLP) chipsets, can easily enable light direction and control in applications such as digital cinema, large venue projection and conference room projectors, as well as in portable and embedded projectors. Such systems can utilize LED or similar sources and usurp legacy systems based on various types of vacuum lamps.

To understand the potential of using LEDs in combination with DLP chipsets, let’s consider an architecture using DMDs for stage lighting. The architecture is based on DLP technology from Texas Instruments (TI) for projection using multiple small-format, narrow-beam light sources. In addition to use with LEDs, the architecture can be adapted to other lighting applications using lasers or laser phosphor. And the concept can scale to lower brightness using a smaller DMD with simpler optics and lower cost.

Introduction to DLP technology

DLP technology is a microelectromechanical system (MEMS) technology that modulates light using a DMD. Each DMD can contain millions of independent mirrors, which correspond to one or more pixels of an image. Each tiny mirror has a diagonal length of only a few microns.

The micromirrors switch very quickly between two states — on and off — to control and redirect incoming light. Due to their size, the switching transition happens in only a few microseconds. Fig. 1 shows a DMD controlling individual mirrors.

FIG. 1. A DMD allows individual control of each micromirror.

The DMD uses micromirrors to control where and when light is directed to a projection target. Many DLP-technology-based systems use a single DMD to control the light. Using a DMD to continually display one color makes system design easier compared to a multicolor system. A single DMD design can also display multicolor images and videos when the system has a color element. This color element can be independent red, green, and blue light sources or a rotating color wheel.

Because of the DMD’s micromirror speed, the DMD displays very small bursts of colored light to independent pixels on a screen or surface. Our eyes integrate these short bursts together and we see them as a brilliantly colorful image or video.

DLP technology has been very successful in cinemas, with over 80% of digital cinemas worldwide using the technology. In addition to cinema, education, and home-projection displays, DLP technology is used in a variety of applications including automotive head-up displays, lithography, spectroscopy, and 3D printing.

Stage lighting systems and DLP’s added value

Stage lighting has long been used to enhance the audience’s visual experience at a live performance or concert. Stage lighting has the ability to highlight a character’s presence in a scene, give the audience a visual representation of a character’s mood, or provide additional visual effects. Current systems can display assorted colors and patterns, but the number of patterns the systems can project relies on the number of GOBOs (“goes before the optics”) that each system can store.

Instead of using GOBO filters to create patterns, a stage lighting system incorporating DLP technology can use a DMD to dynamically create images and patterns. Replacing traditional GOBO filters with a DMD gives producers access to an infinite number of patterns and videos, whether they are a single color or in full color, to create visual effects. Because no additional physical components are required to display the new image, a DLP-based system can display an endless number of images during a performance or show.

An additional benefit of designing a stage lighting system with DLP technology is the removal of mechanical components required to switch GOBOs during the performance. When a traditional system displays a new pattern, a new GOBO must be placed between the illumination source and the projection optics. This action requires a rotation chamber or other mechanical apparatus to switch to the next GOBO, which can take up to multiple seconds to complete.

Due to the fast switching speed and programmability of the DMD, DLP-based stage lighting systems don’t require any mechanical components to display a new image. This characteristic can lead to reduced system size, maintenance, and repair costs.

Although DLP technology provides a lot of advantages in stage lighting systems, GOBO projection still allows for brighter systems. The nearby table lists and compares basic specifications between DLP technology and GOBOprojection.

A system design using DLP technology

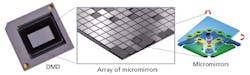

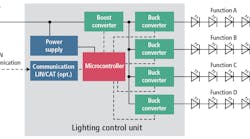

Although DMDs are the essential component of DLP technology, there are system considerations such as the additional electronic components, the optical path from the light source to the DMD and projection lens, the thermal solution, and the illumination source that developers must consider. Fig 2 offers a block diagram of a typical DLP-based system, highlighting the full systemconsideration.

FIG. 2. The block diagram depicts all elements of a DLP-based system.

The electronic solution for a DLP system can be broken into four major components: the front-end processor, the formatter printed-circuit board (PCB), the DMD PCB, and the illumination source driver. Each plays a critical role in the function of the entire system and must be considered when designing the full system.

The front-end processor converts any incoming video or image data into a format that the DLP controller can recognize. You can choose a processor with additional features, such as Bluetooth or Wi-Fi connectivity, to customize and improve the usability of your design. This front-end processor can have application-specific image software for furthercustomization.

The formatter PCB is home to the DLP controller and all required electronics to drive the chip. The DLP controller sends data from the front-end processor to the DMD in a format that the DMD can receive. Each DMD has a designated digital controller, and in some cases a power-management integrated circuit (IC), to optimize itsperformance.

The DMD PCB contains the DMD and all required electronic components to enable its operation. The DMD PCB interfaces with the DLP controller on the formatter PCB to receive data and display the desired image. The DMD PCB is also part of the design’s optical engine.

Driver electronics

The illumination electronics subsystem includes all required components to drive the system’s illumination source. The illumination electronics can interface with the DLP controller and formatter PCB to strategically adjust the light hitting the DMD to improve black levels. In some cases, the illumination driver electronics can also be placed on the formatter PCB to save space.

The thermal solution, while not pictured in Fig. 2, is a critical part of the DLP technology-based system. The function of the thermal solution is to maintain a DMD within the recommended operating temperature range. Having an efficient and effective thermal solution will help increase the lifetime and reliability of the DMD. Some ICs other than the DMD may require a cooling solution as well. Also, light sources such as LEDs usually need efficient thermal management to achieve desirableperformance.

Optical module manufactures (OMMs) in the DLP Products ecosystem currently create a wide variety of optical engines, which come in many different sizes, use many different DMDs, and achieve a large spectrum of brightness levels using different illumination sources. The availability of optical engines allows end-equipment producers to accelerate a product development cycle without requiring specialized expertise andresources.

Optical design considerations

When building the optical system components, it’s important to understand the amount of brightness or lumens needed for the design, the light source, size constraints, and the overall system configuration. A flexible single-chip architecture can be easier to design into a system and allows for both size and cost savings. Because the micromirrors within a DMD have extremely fast on/off transition times, a one-chip DLP implementation can achieve grayscale and color sequential operation with pulsewidth modulation (PWM). To match popular 1-in.-diameter GOBO projectors, developers can turn to a 0.95-in. SXGA+ DLP with a 4:3 aspect ratio. Matching the GOBO characteristics enables the developer to use many available projection optics as is or with smallmodifications.

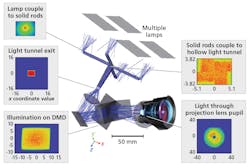

Both lamps and LEDs are typically used in stage lighting applications, though high-lumen-per-square-millimeter LEDs are highly desirable for these systems. Fig. 3 shows an optical design example that uses DLP technology and leverages lamps as the light source; however, it’s possible to use LEDs instead. This would reduce output lumens, which can lower cost in applications demanding lessbrightness.

FIG. 3. A ray-tracing simulation shows the optical path through a DLP system.

The illumination optics system (excluding the projection lens) has only two elements with optical power, which makes it relatively simple and easy to manufacture. Projection lens size depends on the application requirements and can usually be designed and mountedseparately.

Cost-reduction strategies with DLP

This DLP technology-based optical design is easily adjustable to fit smaller, less expensive DMDs. Although this tradeoff will reduce the overall brightness of the design, not all stage lighting applications require a high-lumen brightness specification. If adapting the design to a 0.65-in. DMD, you could still use the same optical architecture but scaled linearly by a factor of 0.707 along each dimension. Shrinking the system saves on the cost of the optical components and light sources, while still achieving half the output lumens.

Using LED illumination sources in a projection system offers a cost advantage over traditional lamps. Using red, green, and blue LEDs instead of a lamp eliminates the need for a rotating color wheel as well as all electronics required to rotate and synchronize the wheel. On top of saving the cost of the color wheel, projection systems using LEDs typically have much more rich colors than systems using lampillumination.

LEDs also have a much longer lifetime than traditional lamps, which allow consumers to save money by not having to replace lamps in their systems. Projection systems with DMDs and LEDs can achieve more than 1500 lm today, which is bright enough to display colorful pictures in bright rooms without sacrificing color. As LEDs become more and more common in lighting applications, their brightness will increase, while their cost will continue to decrease.

Summary

As we have discussed, DLP technology can replace GOBOs in stage lighting to give producers unlimited choices when creating visual effects. Dynamically reprogramming the DMD can create an infinite number of patterns without any mechanical components. Removing motors and mechanical components can potentially reduce the repair and maintenance cost of a stage lighting system.

Using a 0.95-in., SXGA+ DMD in a Type-A package makes it possible to achieve a stage lighting system with a total output brightness of 15,000 lm while using only forced air cooling. You can use smaller DMDs and LEDs for systems requiring less light output and lower cost.

ZHONGYAN SHENG is an optical systems engineer in the TI DLP business. BRANDON SEISER is an engineer in an interdisciplinary rotational program in the TI DLP business.

Zhongyan Sheng got his degree in optics from Zhejiang University, China in 2004. His research interests include different ways of manipulating photons and electrons for conveying information and energy. Sheng has experience in various applications including lighting, optical communication, laser processing, sensing, and displays. In recent years, he has been working on DLP-related solutions for different applications at Texas Instruments, Inc.

Brandon Seiser is currently a product marketing engineer within DLP at Texas Instruments. He holds a BS in electrical engineering from the University of Illinois at Urbana-Champaign and is actively pursuing an MS in electrical engineering from the University of Texas at Dallas. Since joining Texas Instruments, Seiser has focused on new applications of the digital micromirror device (DMD) as well as improving the verification techniques used during the design of device.

Sheng and Seiser have presented their work at Strategies in Light 2018.