Many lighting manufacturers recognize the key role tertiary optics (e.g., Light Shaping Diffusers®) play in creating more Human Centric Lighting (HCL) conditions, or lighting that takes into account the emotional and biological needs of humans. Batwing diffusers are an example of tertiary optics that, when incorporated in the design phase, can dramatically increase the light distribution and eliminate distracting central hotspots common to linear light fixtures.

Evenly distributed light with proper cutoffs for anti-glare can reap significant benefits in the workplace, including increased productivity and a reduction in errors.

HOW DOES A BATWING DIFFUSER WORK?

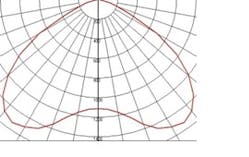

Batwing diffusers use periodic prismatic microstructures that manipulate light with a non-Gaussian profile to achieve different light distributions. When represented on a polar plot, linear prismatic structures are used to create batwing intensity profiles. The center intensity appears to be lower than the side lobes; however, when projected onto a flat surface such as the floor or table, the intensity profile can be considered to be flat. Depending on the apex angle of the prism, the batwing can also provide a cut-off of light outside of a targeted area providing an anti-glare film for luminaires.

Batwing diffuser represented on a polar plot.

Light management films that achieve batwing intensity distributions allow OEMs to design their LED luminaires with flat optics as opposed to bulky reflectors, enabling thinner and sleeker profiles. Recent designs such as Luminit’s Lenticular Batwing use a combination of prismatic and diffuser structures to control the lobe width and angular location, creating high ratios between lit and dark areas while improving the aesthetics of the fixture by providing LED hiding power. Roll-to-roll manufacturing capabilities make lenticular prisms a cost-effective option for linear luminaires because light management is needed along the width of the fixture. An elliptical beam angle such as a 60° x 30° FWHM diffuser is well suited for linear fixtures since the 30° manipulates the lobe distribution along the width of the fixture while the large Gaussian profile with a 60° diffuser homogenizes the LEDs along the length of the fixture. Because the 60° diffuser does not interfere with the lenticular prisms, it fully utilizes the optical stack.

LUMINIT’S SINGLE FILM BATWING SOLUTION

Luminit’s Lenticular Batwing Diffuser (LBD) is a single, double-sided film with lenticular prisms on the front side and a diffuser on the opposing side. The single-film design is not only more efficient than two separate films stacked on top of each other, the combination enables larger spacing ratios for fixtures and allows designers and engineers to adjust hiding power without sacrificing lobe distribution. This is achievable due to Luminit’s advanced seamless double-sided roll-to-roll manufacturing capabilities.

Many OEMs have a fixed extruded aluminum width for the fixture housing with a variety of lengths that are offered as different products under the same luminaire line. Having a seamless roll allows the OEM to maximize yield utilizing the same roll for all of the fixture lengths with little to no waste.

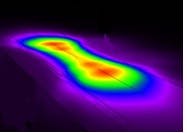

False color image to show intensity of a batwing diffuser.

FUTURE BATWING FORMATS

Luminit is also working on a double-sided, semi-rigid batwing format that will eliminate the need for the outer protected lens of a light fixture, saving manufacturing cost, assembly time and increasing transmission efficiency. Tests show that a semi-rigid material ~0.030” thick is acceptable for linear fixtures because the width of the luminaire is typically under 6 inches, and the material would be rigid enough to prevent sagging.

Replacing the outer lens with a single, double-sided batwing diffuser, however, will require OEM design considerations to achieve optimal performance. The correct orientation of the prism and diffuser is crucial or results will not be accurate. The diffuser needs to face the incident light, with the prism exposed to the environment. This orientation would put batwing prism on the room side because the microstructure is susceptible to scratches. To prevent damage to the prism, Luminit suggests proper equipment be used while handling the material such as gloves and an assembly process that places the protective film over the lens.

CONCLUSION

Optical film manufacturers are making great strides in providing new and innovative products to OEMs striving to create more optically efficient and human-centric fixtures. Luminit’s Lenticular Batwing Diffuser takes this a step further by providing a single-piece solution that reduces cost and assembly time, offers excellent hiding power without sacrificing lobe distribution and the high transmission efficiency for which Luminit is known.

For more information our Lenticular Batwing Diffuser, contact [email protected]. To learn more about Human Centric Lighting, visit http://humancentriclighting.org