1 Dishonest exaggeration in the parameters

With LED marketing flourishing, the LED manufacturers’ profit is decreasing. The fierce competition has also led many factories to use inferior material and cut the producing process, and print the exaggerated parameters on the lamps’ surface or the retail package.

The demand for low price also is the linked with such practices. Therefore,we strongly recommend that to buy the relative test equipment to check it

2 Counterfeit chips

All LED businessman know that the chip is the core of the lamps, which directly determine the performance of the lamps! Some unscrupulous merchants, based on the cost, cheat the unprofessional customers with the poor quality lamps with low-cost and low- quality chips. Finally the buyers will have a loss.

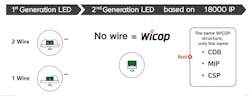

3 Alloy wire VS Gold wire

Many LED manufacturers have tried to develop copper alloys, gold-clad silver alloy wires, and silver alloy wires instead of expensive gold wires. Although these alternatives are superior to gold wires in certain characteristics, they are far less stable in terms of chemical stability. For example, silver and gold-clad silver alloy wires are susceptible to sulfur/chlorine/brominated corrosion, and copper wires are susceptible to oxidation and sulfuration. For packaged silica gel, similar to absorbent breathable sponges, these alternatives make the bond wire more susceptible to chemical attack, lower reliability of the light source, and after some time ,the LED lamp bead is more likely to break and die.

4 The light distribution system design is not reasonable

In terms of optical design, if the design of the street light distribution system is unreasonable, the lighting effect is poor Problems such as "light under the lamp", "black under the lamp", "zebra crossing", and "illuminance unevenness" will appear in the test.

5 Poor Design in Heat dissipation

Regarding the heat dissipation design, If LED chip’s PN junction temperature increase by every 10 degree, then the lifetime of a semiconductor device will decrease multiple. Because of the high brightness requirement of LED street lights, and the tough using environment, If the heat dissipation solution is not perfect,the LED will Ageing age quickly and reduce stability.

So If possible,you can with the help from the 3rd party purchase service to avoid such trips before you purchase or in your purchasing.