INDUSTRY INSIGHTS | Responsive LEDs join forces with daylight to lower energy costs

Energy efficiency is driving growth in the LED lighting market, whether through private enterprises reducing costs or public entities imposing regulations intended to scale back energy consumption and lower the burden on existing resources. The lighting market’s residential and commercial sectors are expanding rapidly as LED lighting surpasses older technologies in energy and cost efficiency.

LED luminaires made up about 19% of total installed lighting units in the U.S. in 2017, but that number could jump to 84% by 2035, according to the U.S. Department of Energy (DOE). The DOE expects nearly 80% of the total LED lighting stock in 2035 to be in the residential sector, and 17% to be in the commercial sector. However, the DOE expects the commercial sector to yield far more significant energy savings — 39% of total savings, in fact.

This article will explore how responsive LED lighting and control systems can capitalize on daylight harvesting for energy savings beyond LED luminaires alone. In conjunction with other building technologies, such systems not only offset the amount of electric illumination required, but they can also reduce the amount of energy consumed by heating and cooling systems — an additional energy burden on commercial facilities.

What makes a lighting system responsive?

The major components of a responsive lighting system include LED light sources, power control devices, and sensors and microcontrollers to provide distributed intelligence required for lighting control and communication with the system’s secondary devices.

Daylight harvesting is one way companies can save energy and reduce ongoing costs in commercial buildings. It uses natural light and heat to illuminate and/or warm a building when possible. For instance, a lighting control system may dim the lights on the east side of a building in the morning as sunlight enters and may slowly bring light levels up throughout the day as the sun makes its way to the west. Potential energy savings depend on how windows are situated relative to the location of the sun and geography. There is more daylight to be harvested in northern California than in Seattle, for instance.

Natural light levels can also be adjusted with tinted or shaded windows to meet the needs of a given workplace scenario. For example, a conference room presentation might not require as much light as employees working at their desks.

Occupancy sensors are key to lighting adjustments. Motion sensors in a particular room or on a specific building floor will automatically request that the lighting control system dim the lights if they sense the area has been unoccupied for a predetermined period. Occupancy sensors may be used in conjunction with a timer function that dims every light in a building after occupants have left for the day, and then increases light levels in the morning when employees typically arrive.

Some lighting and HVAC systems utilize Bluetooth-enabled devices to identify when individuals enter or leave a space. Perhaps an executive on the fourth floor would prefer their office temperature a few degrees higher or lower than the rest of the building. In that case, the internal lighting/heating system can begin making that adjustment when they get out of the elevator or even when they are located pulling into the parking lot in the morning.

Due to variables such as building size, operating hours, and types of LED technologies installed, calculating how much energy a business might save by using lighting control systems equipped for daylight harvesting with sensors and timers can be difficult. However, if the rate of LED penetration continues at its current pace, the DOE projects energy savings nationwide will amount to 4.8 quadrillion BTUs annually by 2035 — approximately half of the total U.S. energy consumption from lighting in 2017.

Window coatings for enhanced lighting/heating efficiency

A lighting control system is only one part of an extensive building management system that includes environmental controls such as heating, air conditioning, air circulation, and air quality, as well as building security and safety. Because of the close relationship between lighting and heating, the building control system should consider environmental comfort and illumination needs together to optimize building comfort and energy efficiency.

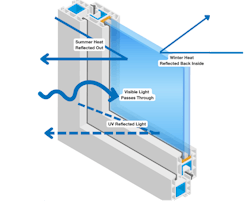

Letting sunlight in through the windows can help illuminate the building’s interior, but it might also raise the internal temperature. Many modern office buildings implement low-emissivity (low-E) glass coatings, a thin transparent layer laid over the glass to reflect infrared energy, which creates heat. Low-E coatings work like the silver lining on the inside of a thermos. During cooler months, the coating seals the warmer air inside the building, preventing it from escaping to the colder exterior. Conversely, when it’s warmer outdoors, materials such as silver in low-E coatings can keep the cool air inside (see illustration). Double-paned windows have a gap between the two glass layers to create a naturally insulating air pocket, similar to that between the inner and outer shells of the thermos.

Passive low-E coatings are designed to absorb sunlight and reduce electric heating costs. In contrast, solar control low-E coatings are designed to reflect sunlight and keep the internal temperature (and air conditioning costs) down. Passive Low-E coatings are most effective when applied to the interior surface of windows (number 4 surface), as far away from direct sunlight as possible. In contrast, solar control coatings are best applied on exterior panes (number 1 surface). There are different standards for measuring the effectiveness of low-E coated glass. U-value measures how much heat dissipates through a window, while visible light transmittance is the amount of light the glass lets in. The solar heat gain coefficient measures how much solar radiation a window absorbs, both directly from sunlight and the reflection of that radiation to the interior glass. The lower a window’s solar heat gain coefficient, the less heat it transmits.

If cooling the building is the goal — and the energy it takes to regulate the interior temperature exceeds the energy the LED lighting requires — a better balance might be struck by using LED illumination while minimizing external sunlight. Air circulation and air quality requirements may also need to be balanced with ambient lighting. In some cases, small temperature differences between areas of the building could create convection currents that naturally help with air circulation, cutting the need for energy-consuming fans to circulate air.

Finding ways to balance these competing needs and requirements might seem complex, but a software-equipped control system can use the building’s activity history to simplify the process. Occupant behavior with regard to temperature and lighting preferences can be evaluated for operational context. Previous settings and results can be stored in the cloud and analyzed to see the most cost- and energy-efficient combinations.

Conclusion

Reducing energy consumption is one of the few areas where public and private sectors seem aligned — businesses and governments are investing more in LED lighting and other energy-efficient technologies. In the commercial sector, the adoption of LED lighting and control systems could reduce the amount of energy consumed by lighting in the U.S. by as much as half in the next 15 years, according to the DOE. Eventually, we may see responsive systems catch up in the residential market as well, as technologies that are scaled to consumer needs and economies.

Consider color temperature for optimal occupant flexibility

With conventional light sources, maintenance crews might have had to change out lamps in ceiling fixtures for particular tasks or employee preferences. For instance, a graphic designer or facilities engineer might prefer a brighter light with a cooler correlated color temperature (CCT) to see their work product more clearly than someone performing administrative or human resources duties. Commercial LED lighting with adjustable CCT and intensity can be modified onsite or remotely with just a few keystrokes, reducing maintenance costs by comparison with, for example, fluorescent technologies.

ALEX PLUEMER is a senior technical writer for Wavefront Marketing, which represents distributor Mouser Electronics (Mansfield, Texas). Pluemer specializes in advanced electronics, emerging technologies, and responsible technology development.

For up-to-the-minute LED and SSL updates, follow us on Twitter. You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn page and our Facebook page.

Alex Pluemer | Technical Writer

ALEX PLUEMER is a senior technical writer for Wavefront Marketing, which represents distributor Mouser Electronics (Mansfield, Texas). Pluemer specializes in advanced electronics, emerging technologies, and responsible technology development.