The Battery Atlanta, a mixed-use development in Georgia’s capital, reached new heights on Feb. 9 with the opening of TK Elevator’s North American headquarters. The approximately $200 million, three-building, 205,000-ft2 complex includes TKE’s 420-ft-tall Innovation and Qualification Center, which contains no fewer than 18 elevator shafts in addition to research laboratories, training facilities, event and meeting spaces, and an educational digital showroom.

One need not step foot inside the 28-story-tall center to glimpse some of its activities, thanks to the full-height glazed curtain wall façade of the tower's east elevation and, moreover, an 11,000-ft2 LED mesh display that spans from 230 ft to 340 ft above grade. Like the glazed curtain wall, the LED mesh runs the 85-ft width of the east elevation, turns, and wraps 15 ft of the building’s north and south elevations.

To date, display animations include a dynamic TKE wordmark, on-brand messaging, an array of colors and animations, and a salutation to the city: “Hi Atlanta!” Though the design possibilities are vast due to the mesh of 700,000-plus RGB LEDs, TKE and project architect Gensler plan to focus on the former’s branding and products featured inside the facility, including TKE’s Twin elevator system, which allows two elevator cars to operate independently in one shared shaft.

“It began simply as a way to celebrate ‘elevator’ in this space,” said Jerry Alexander, the global leader of Gensler's brand design practice and a Houston-based principal. “As we kept developing that concept further, the idea of a digital canvas came into play that would allow us a more dynamic way of communicating what's going on inside.”

For the LED mesh, the team specified the CLRVU Series by Nanolumens, based in nearby Peachtree Corners, GA. The surface-mounted device LEDs are rated for indoor and outdoor use, assuring the project team that the product would perform under stresses associated with the unique building type, such as the significant airflow generated in the elevator hoistways, Alexander said.

The mesh display had to suit not only passersby looking in but also elevator passengers looking out. TKE configured the elevators running along the east elevation with panoramic glass cabins through which passengers can see the LED mesh along with views out to Truist Stadium, metro Atlanta, and the distant mountains, said TKE vice president of engineering Stephen Allen.

“The net effect is that at a distance, [the LED mesh] reads as a complete continuous screen like your TV, but there’s transparency from the inside,” Alexander said. “When you’re riding up these glass elevators, it’s an unobstructed view out, even through the mesh.”

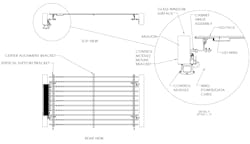

To balance visibility into and out of the tower, Nanolumens and the team created a custom aluminum armature to establish a horizontal pixel pitch of 20 mm and vertical pixel pitch of 75 mm. They also optimized the placement of the LED clusters relative to the curtain wall glazing to minimize reflectivity. “We did quite a few mock-ups,” Alexander said.

The resulting configuration tucks the LED mesh between the curtain wall’s 10-in.-deep mullions — out of the elevators' hoistways — and right against the interior face of the insulated curtain wall glazing. When the LEDs are off, the mesh becomes largely indiscernible, Alexander said: “It doesn't encumber the building and you look at a beautiful curtain wall that extends from ground to sky.” The team positioned the diodes so they wouldn’t appear as millions of hot spots to viewers when the LEDs are on.

The armature was designed as hinged panels, ranging from 3 ft to 4 ft tall and nearly 5 ft wide, to facilitate LED and glass maintenance. The diodes are rated for 100,000 hours, which Alexander estimated translates into 15 or 20 years of operating life. Atlanta Rigging installed the LED mesh over three months, in coordination with other building trades.

Energy efficiency is a priority for the overall complex, which is pursuing LEED Gold certification from the U.S. Green Building Council. The team is monitoring the mesh technology's energy consumption, which will vary based on which graphics and colors are created through additive color mixing. Alexander estimates the diodes will be run at 75% of their maximum output during the day, and between 30% and 40% at night. To reduce the display’s contribution to light pollution, the LEDs are hooded to direct their light downward, where their primary audience is situated.

Apart from the LED mesh display, the full height of the elevator shafts can be flooded with dynamic light from LED light cannons. A third layer of lighting comes from solid-state fixtures installed on the individual cabs traveling within the illuminated hoistways.

To orchestrate this multidimensional, multimedia display, the project team developed a custom, PC-based software with Nanolumens and technology integrator AVI-SPL that can process and translate different data streams into a designated action or visual response. The program also ensures the images displayed on the LED mesh retain continuity across the curtain wall’s horizontal and vertical mullions.

Though other lighting systems in the center are controlled by other platforms, including software by Pharos Architectural Controls, the PC will be the mainframe. “We need the fidelity available to have both of those things tightly coordinated,” Alexander said, “especially when we start to overlay movement of the elevator.”

In the short term, visitors to The Battery Atlanta can expect to see content promoting TKE and elevator technology in the city skyline, on the tower exterior. Future inputs might include the movement of individual elevator cabs, whose locations within the different shafts are tracked. Exploring the potential of LED display is one reason TKE and Gensler are still collaborating after the headquarters’ opening. “We're continually evolving technologies with TKE,” Alexander said, “and it’s going to continue to evolve and change.”

Constructed in two years, with design commencing three years earlier, the TK Elevator headquarters required coordination across multiple building trades. In addition to the companies previously mentioned, Impact Development Management served as the project manager, Brasfield & Gorrie as the general contractor, Walter P. Moore as the structural engineer, Kimley-Horn as the civil engineer, Inglett and Stubbs as the electrical contractor, and Harmon as the curtain wall consultant.

Beyond its technical achievements, the project itself is an innovation — a mixed-use, industrial testing facility situated in an active urban environment. Though TKE has security protocols in place and is showing only mature technologies through the glazed curtain wall, the team expects the liveliness of The Battery Atlanta to contribute to the headquarters’ success. TKE employees and local residents, Alexander said, will both enjoy “the benefit of having [the headquarters] embedded in the community.”

Project details at a glance

Client: TK Elevator

Architect: Gensler

Curtain wall consultant: Harmon

Display technology provider: Nanolumens

Display rigging installer: Atlanta Rigging

Integrator: AVI-SPL

WANDA LAU is editorial director of LEDs Magazine and Smart Buildings Technology. She previously served as executive editor of Architect magazine and worked for a decade in the architecture, engineering, and construction industry.

For up-to-the-minute LED and SSL updates, why not follow us on Twitter? You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn Company Page and our Facebook page.