The 1980s inventions enabling the synthesis of high-quality gallium-nitride (GaN) on a common substrate material (sapphire) provided an unprecedented platform for the development of visible-spectrum LEDs: a fully optically transparent and robust compound semiconductor material system specifically suited for the efficient generation of blue light, the primary light source necessary to enable full color solid-state lighting (SSL). This Nobel Prize winning work sparked decades of global investment and massive research and development that would completely revolutionize lighting and displays.

Even in the early days of developing this material system, it was understood that aluminum/gallium (Al/Ga) substitution could generate AlGaN materials, providing a platform for wider-bandgap (shorter-wavelength) emitters. In particular, the importance of ultraviolet germicidal irradiation (UVGI) for surface, air, water, and food disinfection was already well known at the time (primarily using mercury, Hg, lamps) and not lost on LED researchers who immediately recognized the potential benefits of a compact, high-intensity, solid-state, Hg-free source of radiation. Yet the performance of these AlGaN-based LEDs, emitting in the ultraviolet C-band (UV-C), has lagged dramatically behind that of their blue brethren in terms of efficiency and cost. Why? Many assume this is due to low market pull and associated low investment (compared to the situation for displays and illumination, for example), but a more fundamental aspect is technical: GaN, the backbone semiconductor for SSL, is not transparent to UV-C radiation. This aspect is devastating to the performance of any optoelectronic device, and solutions to this problem have been incredibly elusive, until now.

Photon extraction efficiency cannot be ignored

Photons emitted within an optically dense material (such as GaN or AlGaN) must exit that material at fairly low angles of incidence in order to match necessary electromagnetic boundary conditions and radiate outside. For example, blue light in GaN experiences a refractive index of ~2.4, resulting in an escape probability into air of approximately 5%, which means light may bounce around up to 20 times inside a GaN-based LED chip before it finally escapes. If such a device included no optical loss mechanisms, this wouldn’t matter, but that’s not the case. Even a 10% loss per pass can be catastrophic to overall performance, and the situation is similar for UV-C radiation in AlGaN when compared to blue light in GaN.

Now, imagine embedding an opaque (~100% absorbing) layer inside such a chip. In that case, generated photons have just one chance to escape, or they are lost, putting a ceiling on photon extraction efficiency at ~5%. Even using an encapsulating medium (to increase the ambient refractive index) will, at most, double the escape probability to ~10%. This is the situation for all UV-C LED structures that include GaN layers: The photon extraction efficiency is limited to a paltry ~5‒10%, putting a very low ceiling on the entitled power-conversion efficiency (PCE) of the LED.

UV-C-transparent p-type layers

Why does one use GaN in UV-C LEDs? The reason is the fundamental need to have good p-type behavior for a functioning diode. For GaN, the ionization energy for magnesium (Mg, the acceptor impurity) is quite high, yet it is manageable and allows producing approximately one positive charge carrier (hole) for every ten or so Mg impurity atoms. For AlGaN, the situation is worse, and becomes dramatically so by the point at which the Al/Ga ratio reaches what is necessary for UV-C transparency, generally resulting in highly resistive p-type material that does not easily pass electrical current and to which it is difficult to make ohmic contact, resulting in unworkably high forward voltages. To avoid this problem, the UV-C LED industry has for years tried to make do with GaN:Mg p-contact layers, in spite of the very high price to be paid on photon extraction efficiency. The result has been devices with reasonable forward voltages but with paltry single-digit PCEs, relegating UV-C LEDs to niche applications, as for blue LEDs in the 1990s.

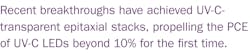

Thankfully, recent breakthroughs have achieved UV-C-transparent epitaxial stacks, propelling the PCE of UV-C LEDs beyond 10% for the first time. Last February, at SPIE Photonics West in San Francisco, RIKEN/Panasonic announced they were able to successfully incorporate a p-type AlGaN:Mg stack and, while the resistivity of the layers resulted in an admittedly high forward voltage (~9V versus a bandgap voltage of 4.5V at 275 nm), they achieved an external quantum efficiency above 20% (a lower limit to the extraction efficiency, and a testament to the improvement made possible with the fully transparent epitaxial stack).

Tunnel junctions are another active area of research, in which p-type layers can be “replaced” by n-type layers and offer improved transparency. Meanwhile, Bolb, Inc., from Livermore, CA, recently developed a field-assisted tunneling contact, based on AlN and exploiting built-in polarization fields of the Wurtzite AlGaN crystal structure, to form an all-transparent UV-C LED with low forward voltage. Following up from earlier work, the company’s best reported devices now exhibit a 6.0V forward voltage and a PCE of 10.6% at 271 nm, and it is shipping UV-C LED products today, including high-power modules and arrays. Perhaps even more remarkable, Bolb’s LED design has yet to include many of the sophisticated photon extraction techniques that it is entitled to, such as those used in blue LEDs.

Roadmap for UV-C LEDs

Indeed, these breakthroughs in UV-C-transparent epitaxial stacks entitle, for the first time, the UV-C LED sector to the technology improvement roadmap that performed so well for blue LEDs and transformed the lighting industry. The best reported GaN-based visible-spectrum LEDs exhibit PCEs above 80%. These devices have estimated photon extraction efficiencies approaching 90%, compared to 5‒10% for conventional UV-C LEDs using absorbing p-GaN contact layers (which cannot make use of the “tricks” that worked for blue LEDs). Transparent UV-C LED structures, as demonstrated by Bolb, Inc. and RIKEN/Panasonic, can absolutely make use of such tricks, such as reflective p-contact metallization, patterned substrates, textured surfaces, microcavity effects, and volumetric shaping. The wide range of techniques for improving blue-LED photon extraction efficiency (many based on patents that have — or are nearly — expired) provide a blueprint for how they can be exploited and employed for UV-C-transparent LED structures, potentially leading to a dramatic acceleration in improved performance (and reduced cost/W) in the coming decade, ushering in game-changing applications for health and safety, much as GaN-based blue LEDs did for mobile, displays, and illumination.

Market analysts, even prior to COVID-19, predicted a UV LED market exceeding $1 billion in a few years, to be compared with the lighting LED market, which was $5.8 billion in 2019, after growing for many years now. In addition, large LED players, including Nichia and San’an, are notably investing in the UV-C LED market, no doubt in expectation of healthier profit margins compared to today’s general lighting LEDs. This sets up an interesting dynamic, since these large companies have capital and established sales channels, but do not necessarily have access to the technology or intellectual property that pure-play UV-C LED startup companies have, similar to the situation that red LED companies experienced when GaN-based blue LEDs came on the scene in 1990s. However, there remain peculiar challenges for UV-C LEDs compared to their blue LED counterparts.

Figure 1 illustrates some of these comparative challenges, for the case of blue and UV-C LED structures grown on sapphire and incorporated into a flip-chip design (suitable for high-power operation). On the epitaxial side, low adatom mobility means AlGaN deposition tends to be more “sticky” than GaN deposition, thwarting lateral growth and making dislocation reduction more challenging. Indeed, most UV-C LED structures have dislocation densities ~10× higher than blue LEDs, which reduces internal quantum efficiency. This same sticky behavior also makes growth on patterned sapphire substrates (PSS) challenging, meaning that UV-C LEDs cannot as easily make use of enhanced extraction efficiency using this technique common for blue LEDs.

In addition to the aforementioned p-contact layer challenge (GaN:Mg is transparent in the blue, but opaque in the UV-C), there is also the issue of the p-side ohmic contact reflectivity. For blue LEDs, silver (Ag) is both a good ohmic contact and very high optical-quality mirror. Unfortunately, due to plasmon resonance, Ag does not maintain those reflective properties in the UV-C (its reflectivity drops below 20%); therefore, alternative metallizations are required. One such metallization working reasonably well today for UV-C LEDs is rhodium (Rh), which makes a decent ohmic contact to AlGaN but has a reflectivity in the UV-C of ~70%, compared to ~90% for Ag reflectivity in the blue. Finally, blue LEDs benefit from InGaN/GaN quantum wells (QWs), which exhibit only transverse electric (TE) dipole radiation. This means that more light is radiated upwards, out of the primary surface of the LED chip, than sideways, which further helps extraction efficiency. For AlGaN/AlGaN QW structures, as Al/Ga ratio is increased (e.g., to achieve shorter wavelength emission), transverse magnetic (TM) dipole radiation emerges, increasing the relative amount of lateral radiation, which can be trapped within the epitaxial layers and is more susceptible to loss within the LED chip.

While there appear to be many disadvantages to overcome, they are no more daunting than the original challenges that GaN-based LED researchers encountered in comparison to more traditional infrared and red LED material systems, i.e., aluminum-gallium arsenide (AlGaAs)/GaAs and aluminum-gallium-indium phosphide (AlGaInP)/GaAs. Besides, there may be some advantages. For example, the crystalline lattice mismatch between AlN versus GaN is much smaller than InN versus GaN, meaning the AlGaN system provides a wider range of flexibility regarding bandgap and layer structure engineering. This could mean that Auger recombination, the cause of “LED droop” for GaN-based blue LEDs, may be a smaller problem for AlGaN-based UV-C LEDs. Armed with such advantages, the availability of UV-C-transparent epitaxial structures, and over twenty years of lessons learned (including what did not work so well) regarding blue LED development, UV-C LED researchers are now well positioned to execute a rapid performance improvement roadmap similar to that for blue LEDs in the 2000s.

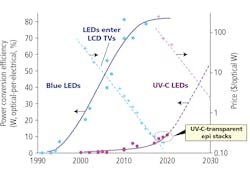

Indeed, if UV-C LEDs begin to match the rate of progress for blue LED performance and cost as demonstrated in the preceding decade (which in fact exceeded the well-known Haitz’s Law), by 2030 they will have marched past 50% PCE and be available at price points approaching $1 per optical watt. This projection is substantiated by the best reported performance in literature, as well as quotations on price from leading UV-C LED manufacturers (Fig. 2). As a comparative reference point, at $10 per optical watt, blue LEDs already began to enter the TV market. Within two years after early penetration of that market, they became the dominant backlighting technology for LCD TVs, and within two years after that, completely wiped out the incumbent light source: cold-cathode fluorescent lamps (CCFLs). The analogy between blue LEDs and CCFLs, and UV-C LEDs and Hg lamps, is clear. In addition to a fundamentally higher entitlement on performance, LEDs — compared to discharge lamps — are sources of directed radiation that can be much more efficiently controlled and utilized compared to low-radiance emission from an omnidirectional, bulky tube. Once a solid-state technology can compete with tube-based lamps on a cost-of-ownership basis, the preferred solution is undeniable, and the story of how blue LEDs replaced CCFLs will play out again as UV-C LEDs replace Hg lamps in myriad applications, and enable new applications that Hg lamps never could have fulfilled.

UVGI and outlook toward ‘far UV’

As mentioned earlier, UVGI employing UV-C radiation is a well-known technology for eradicating pathogens. The UV-C band around 260‒280 nm, near the peak of RNA/DNA absorption, appears today to be the sweet spot for UVGI using LEDs (even more effective than the 254-nm Hg line). UV-C was very recently shown to be extremely fast in inactivating the SARS-CoV-2 virus, the one responsible for COVID-19. More thorough studies are anticipated, but based on these results and even accounting for optical losses in fabrics and general guard-banding, we can expect high levels of inactivation within seconds to minutes in practical use of UV-C LEDs, opening up a new set of product concepts around healthcare worker safety, just at a time when novel solutions are desperately needed. Far from being “security theater,” UV-C LEDs are high-radiance, compact, solid-state emitters that offer all the controls necessary to provide a unique toolkit for developing safe and effective solutions not only for hospital, air, water, and food safety but also for protection of office workers, shoppers, and commuters in a post-COVID-19 world.

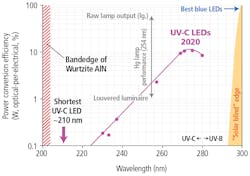

While research on UV-C LEDs is primarily focused at ~260‒280 nm, other wavelengths are also interesting, in particular what has been called the “far UV” band near 220‒230 nm, which is demonstrated to have germicidal efficacy while expected to be less harmful to exposed human skin (due to higher absorptivity and thus lower radiation-penetration depth). The PCE of best reported UV-C LEDs, as a function of wavelength, is shown in Fig. 3. Performance falls off fast as emission wavelength decreases (or Al/Ga ratio increases). Broadly, this happens because all the concerns illustrated in Fig. 1 become relatively more challenging as Al/Ga ratio increases. So far, the shortest emission demonstrated is at 210 nm, from an AlN p-i-n diode structure.

It is notable that some of the best-reported shorter-wavelength UV-C LEDs are ones developed on bulk AlN substrates, not sapphire. One possible reason is the lower dislocation density, which is more than 1000× lower in the case of epitaxial growth on AlN versus sapphire. However, bulk AlN crystals (grown by sublimation) today have a relatively high concentration of impurities and are not fully transparent, having an absorption coefficient in the UV-C that translates into ~90% loss per millimeter of travel. AlN and AlGaN quasi-substrates based on hydride-vapor-phase-epitaxy (HVPE) have been demonstrated, and may provide an alternative path, albeit likely at a higher price point than sapphire-based UV-C LEDs.

Finally, other techniques to provide very low dislocation densities for AlGaN on sapphire will likely be developed. With all the creativity behind III-nitride device research and engineering, and more than two decades of proven ideas to draw upon, it is certain that, backed by suitable investment, we can expect performance of AlGaN-based LEDs to dramatically improve across the entire UV-C wavelength regime.

Conclusion

The COVID-19 pandemic caused by SARS-CoV-2 has raised awareness regarding the significant potential of UV-C LEDs and sparked strong interest in innovation around this new technology for developing new tools and capabilities for inactivating bacterial and viral pathogens, over and above chemical treatments and/or reliance on Hg-containing tube lamps. This awareness, and the associated pent-up demand, coupled with the recent technical breakthroughs in UV-C-transparent epitaxial structures and the roadmap opportunity it affords, will usher in an unprecedented era of UV-C LED and application development now and in the coming years, opening up an untapped (and likely, underestimated) billion-dollar market for LEDs while having a profound impact on making our world cleaner and safer.

Links for more information

LEDs Magazine considers ultraviolet (UV) LEDs an emerging market with multiple application sectors that will mature as product developers and manufacturers address challenges such as those outlined here to achieve volume production and increase uptake. You’ll find several articles on related UV LED topics below.

Emerging applications for UV LEDs drive broad interest

Reconsider UV-C LED lifetime for disinfection based on development decisions

Research realizes innovation in fabricating reflective coatings for high-power UV optics

Expert webcast speaker sets expectations with regard to UV-C

REFERENCES

Zhang et al., Jpn. J. Appl. Phys., 58, SC (2019).

Zhang et al., Proc. SPIE, 1094002 (2019).

Narukawa et al., J. Phys. D: Appl. Phys., 43, 35 (2010).

Krames et al., IEEE J. Disp. Technol., 3, 2, 160‒175 (2007).

Allied Market Research, “UV LED Market by Type (UV A, UV B, and UV C): Global Opportunity Analysis and Industry Forecast, 2018‒2026”.

Wright, LEDs Magazine, 17, 3 (April 2020).

Chen, LEDinside.com, Feb. 11, 2019.

Kneissl et al., Nat. Photon., 13, 233–244 (2019).

NPD DisplaySearch press release, Digital TV News (Oct. 24, 2012).

Halper, “Boston University validates Signify UV-C for coronavirus deactivation,” LEDs Magazine (June 16, 2020).

Taniyasu et al., Nature, 441, 325–328 (2006).

Yoshikawa et al., Appl. Phys. Exp., 13, 2 (2020.)

Kuittinen et al., Phys. Status Solidi C, 11, 3-4, 405‒407 (2014).

*The following references were used to create the data points referenced in Figures 2 and 3 in this article.

Adivarahan, Appl. Phys. Lett., 84, 4762 (2004).

Cich et al., Appl. Phys. Lett., 101, 223509 (2012).

Fujioka, Appl. Phys. Exp., 3, 4, 1001 (2010).

Grandusky, Appl. Phys. Exp., 6, 3, 2101 (2013).

Hurni et al., Appl. Phys. Lett., 106, 3, 1101 (2015).

Hirayama, Phys. Status Solidi A, 206, 6 (2009).

Jo et al., RIKEN, SPIE Proc., 11302‒46 (2020).

Kneissl et al., to be published in APL.

Krames et al., IEEE J. Disp. Technol., 3, 2 (June 2007).

Narukawa et al., Jpn. J. Appl. Phys., 45, L1084–L1086 (2006).

Narukawa et al., J. Phys. D Appl. Phys., 43, 35 (2010).

Pernot, Appl. Phys. Exp., 3, 6, 1004 (2010).

Shatalov et al., Appl. Phys. Exp., 5, 8, 2101 (2012).

Takano et al., Appl. Phys. Exp., 10, 3, 1002 (2017).

Wierer et al., Appl. Phys. Lett., 78, 3379 (2001).

Yamada et al., Jpn. J. Appl. Phys., 41, L1431 (2002).

Yoshikawa et al., Appl. Phys. Exp., 13, 2, 2001 (2020).

Zhang et al., SPIE Proc., 10940, 1094002 (2019).

Zhang et al., Semicond. Sci. Technol., 33, 07LT01 (2018).

Zhang, Appl. Phys. Lett., 81, 4910.

Zhang et al., Appl. Phys. Lett., 85, 23, 6 (2004).

Zhang, Jpn. J. Appl. Phys., 44, 10 (2005).

Zhou, Appl. Phys. Lett., 89, 241113 (2006).

Milonova et al., Lighting Res. Technol., 49, 6 (2017).

Get to know our expert

MIKE KRAMES, PhD, is president of Arkesso, LLC, a consulting firm based in Palo Alto, California, specializing in wide bandgap semiconductors and applications. Disclosure: Client companies of Arkesso include those active in the UV-C LED space.

For up-to-the-minute LED and SSL updates, why not follow us on Twitter? You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn Company Page and our Facebook page.