This article was published in the November/December 2013 issue of LEDs Magazine.

Visit the Table of Contents and view the e-zine version in your browser. You can download a PDF of the magazine from within the browser e-zine.

+++++

Quantum dot (QD) technology has promised to enhance LED usage, making LCD TV images more vivid and improving efficacy in warm-CCT, high-CRI solid-state lighting (SSL). Thus far, however, cost, reliability, and lifetime issues have prevented broad commercial deployment. But the technology has progressed to the point that the TV application, with relatively shorter usage hours compared to general lighting, can adopt the technology.

Due to their high resolution, low cost, and thin form-factors, LED-backlit LCDs have become the standard for mobile devices and TVs, although color performance has lagged. (For more details on how LCDs and backlights work, see sidebar at end.) Displays on popular backlit LCD tablets can only express about 20% of the color a human eye can see, while LCD HDTVs can express only about 35%. To achieve more vivid, realistic color, display manufacturers have developed a variety of new technologies such as discrete RGB LED backlights, yttrium aluminum garnet (YAG) enhanced with red phosphor, and organic LEDs (OLEDs). All are beset with cost, scalability, and durability issues that have hampered widespread deployment.

One of the most promising new color enhancement technologies for backlit LCDs is QDs, a nanocrystal material that can be tuned to emit an optimized narrow spectrum of light. The unique semiconductor and optical properties of quantum dots make them attractive for a broad range of applications, from SSL, silicon photovoltaic cells, and quantum computing to cellular imaging and organic dye replacement. Due to the high production volumes and ease of integration with existing manufacturing processes, LCD suppliers seem to have taken a particular interest in QDs. By augmenting their backlight units (BLUs) with QDs, LCD manufacturers are able to create vivid displays that can exceed 55% of the spectrum a human eye can detect.

Why quantum dots?

Where vivid color and high efficiency are the objectives, the ideal white light is one that can be tuned to generate lots of visible energy narrowly focused on the primary red, green, and blue wavelengths used by the subpixel filters while producing very little light between. QDs do just that. The tiny nanocrystals, smaller than a virus, emit narrowband light when excited by a photon source.

Unlike conventional phosphor technologies like YAG, which emit with a fixed spectrum, QDs can be fabricated to convert light to nearly any color in the visible spectrum by simply varying the size of the dots. Size and bandgap energy are inversely related, so as the size of the QD decreases, emission frequencies increase, resulting in a color shift from red (low energy) to blue (high energy) in the light emitted. Lifetime fluorescence is also determined by the size of the QD, with larger dots showing a longer lifetime.

By carefully controlling the size of the crystals as they are synthesized, the spectral peak output can be set to within 2 nm of nearly any visible wavelength. Such control enables QDs to be tuned so the backlight spectrum matches the color filters, thereby facilitating displays that are brighter and more efficient, and produce truly vibrant colors.

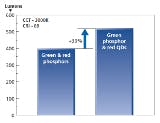

Integrating QDs with the BLU

Quantum dot approaches are similar to phosphor technologies in the way they attempt to engineer the white light spectrum. As with YAG, a blue GaN LED provides the source light. QDs then downconvert a portion of the blue light into narrowband red and green spectrum, thereby achieving a white light that is rich in red, green, and blue and matched to the subpixel filters. QDs can be tuned (by varying the size) to emit at any wavelength longer than the source wavelength with very high efficiency (over 90% quantum yield under ideal conditions) and with very narrow spectral distribution — just 30–40 nm full width at half maximum (FWHM). This high spectral efficiency in turn reduces display power consumption by 20% compared to other high-gamut color-enhancement techniques — a key factor in meeting Energy Star requirements in TVs or extending battery life in portable devices where displays often consume 40% of the power.

As with YAG, QD backlight technology is easy to integrate with existing LCD manufacturing processes. QD upgrades require no line retooling or process changes. So manufacturers who have invested billions in LCD plants and equipment can quickly deploy QD-enhanced LCD panels that offer the color and efficiency of the best OLEDs at a fraction of the cost.

3M, for example, is now using QDs supplied by Nanosys, Inc. to offer a quantum-dot enhancement film (QDEF) a thin, optically-clear sheet with red and green dots that replaces the existing diffuser film in the reflective cavity of an LCD backlight. This packaging, explains 3M marketing development manager Art Lathrop, "not only simplifies integration and protects the dots against flux but boosts efficiency by recycling light emitted in the wrong direction."

3M has initially focused on mobile displays where the industry has put more emphasis on premium quality and displays sell for a relatively high price per square meter. Larger displays are not only more price sensitive, Lathrop added, but also heavier users of QDs in the film implementation. When an application grows linearly (long strips of displays, for example), the QD film and the number of dots used in the film grows linearly as well, so cost is not a problem. However, when the application grows more by area than length — as in a TV display — then the number of QDs required for the film grows exponentially with display size, and the cost of QDs becomes a significant factor. Lathrop expects this issue to abate as the raw QD materials get cheaper and packaging/manufacturing (inexpensive film vs. glass, for instance) becomes the driver of overall QD cost. Until then, 3M will focus on smaller displays with lower raw material costs such as consumer mobile devices.

Drop-in QD technology

QD Vision also provides a drop-in technology called Color IQ, though instead of packaging the QDs as a film, QD Vision employs a glass tube that mounts on the edge of the display (Fig. 1). Unlike the 3M film, which scales geometrically, the rail solution scales linearly, making it more effective for larger displays. "With an edge solution like Color IQ," said QD Vision CTO Seth Coe-Sullivan, "we utilize about one-hundredth of the QD materials relative to a film solution of the same screen area. This is why you see 3M launching in the Kindle with a screen area of one-sixtieth of a square meter, while we are in big-screen Sony TVs."

Nanosys CEO Jason Hartlove concedes that the film solution is a heavier dot user but puts the differential at about 5x. The shorter optical path in the edge solution, he argues, requires a much higher dot density (less opportunity for recycling) and is also susceptible to aggregation and quenching, which reduces the dot's light output and requires additional LEDs to get the same brightness.

Pacific Light Technologies got its start in nanotechnology developing QDs for the solar industry, where the dots are used to convert solar energy into a low-energy format that can be utilized more efficiently by solar panels. From there, the company branched off into SSL, using QDs to create warmer lighting solutions. More recently, the company has attracted interest from display makers. Their key differentiator, according to vice president of marketing Julian Osinski, is the ability to fabricate dots directly onto blue LEDs, eliminating the need for a separate QD subassembly (Fig. 2). "A display requiring coverage over the full surface can be on the order of 10,000x the surface area of the LED chips used to illuminate the display," said Osinski, "and since the amount of QDs required scales with surface area, that means 10,000 times less QD material is required for on-chip use compared to off-chip."

Pacific Light uses the same process for adding dots to LEDs that manufacturers use to add phosphor. The QDs are synthesized in a reactor vessel, separated out, mixed into a silicone, and then applied to the chip. "One nice advantage," noted Osinski, "is that unlike phosphors, there is no settling of QD particles, resulting in more stable color points during manufacturing." Pacific Light Technologies is currently shipping red dots, with plans for green dots in the future.

Quantum dot reliability

The useful life of the QDs is a complex issue heavily dependent on the application and the operating conditions. Fundamentally, what kills dots the fastest is oxidation. Beyond that, assuming that the dots are very well protected from oxygen, they also deteriorate from being used (like most emitters), and that deterioration accelerates with elevated heat and flux, particularly flux. Temperature at the film is about 40°C vs. 90°C at the edge, and 140°C at the LED, said Hartlove of Nanosys. Flux is 25 MW/cm at the film, 1–10W/cm at the edge, and from tens to hundreds of watts per centimeter at the LED — five orders of magnitude from the film to the LED.

3M's testing, said Lathrop, shows that in most consumer applications QDEFs last for 20,000 to 30,000 hours of operation before luminance drops by 15%. A larger drop will start to result in a noticeable color shift (blue is not impacted). 3M's next-generation product is targeting twice that lifetime, not because display makers are looking for 60,000+ hours but because they want to use them in hotter displays (all-in-one PCs or specialty displays, for example).

QD Vision's edge solution, which encapsulates the dots in a glass tube, provides an excellent barrier to oxygen, as well as other advantages such as lower volume utilization, low-tech barrier materials, and excellent color uniformity (no blue light leakage). "Our edge implementation also presents unique challenges," explained Coe-Sullivan. Color IQ sits closer to the LED backlight than a film, so the dots must withstand higher heat (100°C) and flux (100x that of a film). Nonetheless, Coe-Sullivan claims to have overcome those challenges and rates the Color IQ lifetime at between 30,000–50,000 hours, essentially the same as present-day LEDs.

Pacific Light Technologies' approach to mounting dots directly on the LED may offer the most significant potential cost and performance advantages of all (Fig. 3) but also the greatest challenges with regard to reliability. In addition to higher temperatures, flux in particular can be 50x that of an edge solution. "In general," noted Osinski, "white-light LED lifetimes are limited by the silicon-phosphor combination on the chip more than the chip itself, and that remains the same with QDs, where silicone yellowing also contributes to aging blue LEDs." Reliabilities are still being established because they require very long test times, but Pacific Light claims to have already demonstrated operation over thousands of hours.

OLED

One of the chief competitive technologies to QDs where color quality is of primary importance is OLED, which emits light directly and requires no backlight or LCD filter. In addition to excellent color gamut comparable to QDs, OLED displays feature faster response times and refresh rates, improved brightness, a greater contrast ratio (both dynamic range and static, measured in purely dark conditions), a wider viewing angle than LCD implementations (with or without QD augmentation), and the ability to display true blacks.

Perhaps the biggest technical problem for OLEDs is the limited lifetime of the organic materials, primarily for the blue OLEDs. Blue OLEDs historically have had a lifetime of around 14,000 hours to half original brightness (five years at 8 hours a day) when used for flat-panel displays. Red and green OLEDs offer 2–3x that lifetime. The faster degradation of blue OLEDs relative to red and green creates color balance challenges, requiring either additional control circuitry, or optimization of the red, green, and blue subpixel sizes in order to equalize color balance at full luminance over the lifetime of the display. A blue subpixel, for example, may need to be 100% larger than the green subpixel, whereas the red subpixel may need to be 10% smaller than the green.

High cost has also hampered the widespread use of OLEDs in larger mass-market displays. Eliminating the backlight and LCD filter provides significant cost savings and allows for a thinner display, but the fabrication of the OLED substrate is presently more costly than that of a thin-film transistor LCD. Down the road, the ability to fabricate OLEDs on flexible plastic substrates and the utilization of processes like roll-to-roll vapor-deposition and transfer printing will offer potential cost advantages. For now, though, large-screen applications require low-temperature polysilicon backplanes that cannot currently be used on large-area glass substrates. As a result, large OLED displays are limited to relatively high-end applications, with OLED TVs from LG and Samsung selling in the $10,000 range. On the other hand, Sony uses QD Vision's technology, branding it Triluminos, in its 4000-pixel Ultra HD LCD TVs that start at about $3500 (Fig. 4). But Sony has also included Triluminos technology in some higher-end standard HDTV sets such as a 55-in. model that sells for around $2000.

Electroluminescent QDs

Even as OLED strives for economies of scale and process improvements that will bring costs down, QD makers like QD Vision are already working on the next generation of technology — electroluminescent QDs that will combine the customizable, saturated, stable color and low-voltage performance of inorganic LEDs with the solution processability of polymers. The new technology, Coe-Sullivan explains, will provide a reliable, energy-efficient, highly tunable color solution for displays and lighting that is less costly to manufacture and that can employ ultrathin, transparent, or flexible substrates.

Quantum-dot light-emitting diodes (QLEDs) are electroluminescent colloidal quantum dots that generate light when excited electrically. Like OLEDs, QLEDs require no backlight or LCD filter. QD Vision claims that its printable thin-film QLEDs match or exceed NSTC color standards for displays without the need for color filters. The excellent color performance of QLEDs ultimately translates into a 30–40% luminance efficiency advantage over OLEDs (at the same color point), which require lossy color filtering to achieve a similar color performance. QLEDs also feature a lower operating voltage, exhibiting turn-on voltages at the bandgap voltage of the material. This gives QLEDs the potential to be more than twice as power efficient as OLEDs at the same color purity.

To reduce cost for QLED-based, full-color, active-matrix displays and lighting devices, QD Vision is developing large-area quantum-dot printing techniques that utilize ultrathin flexible substrates. Today's LCDs and LED chips are fabricated on glass and crystalline substrates, making them inherently expensive and fragile for mobile and large-area applications. QLEDs, by contrast, are only a couple hundred nanometers thick, making them virtually transparent and flexible, and highly suitable for integration onto plastic or metal foil substrates as well as other surfaces.

QLEDs are still in the early development stages, yielding only 10,000 hours at low brightness, but in theory are a more stable light-emitting material than organic dyes. Meanwhile, the company is already offering high-quality electroluminescent-grade QD materials suitable for certain products that require precise color solutions in an ultraslim form factor. Among these are monochrome visible and infrared displays, and lighting devices for machine and night vision applications.

Nanosys' Hartlove agreed that the QLEDs are the way of the future. "When emissive pixels will overtake LCDs we cannot say. LCDs get better every day." Within ten years, however, he expects the manufacturing and production advantages of QLEDs (solution chemistry and roll-printed emitters) to overtake GaN substrates and wafer-based processing — and not just for displays but also general lighting. Right now, the focus is on the ability of QDs to outperform phosphors in the color arena, but eventually the properties of the raw materials will fade in significance, and it will come down to manufacturing, where the ability to print narrowband emissive pixels on thin films in high volume will produce high-quality color inexpensively — without the need for color management.

++++Backlight enhancement

Liquid-crystal displays (LCDs) combine a light source (the backlight unit, or BLU) with a liquid-crystal module (LCM). The BLU provides a uniform white sheet of light behind the LCM. The LCM contains millions of pixels, each of which is split into red, green, and blue subpixels. By controlling the amount of time each subpixel filter is open (allowing light to pass through it) and making use of the human eye's persistence of vision, the LCD can display any color that can be rendered from a combination of red, green, and blue at each pixel location. The color filter on each subpixel separates its component color from the white light of the BLU. For example, the red color filter on the red subpixels blocks the green and blue light.

The fidelity of each color is a function of the quality of light in the BLU and the color filters. The narrower the filters, the narrower the backlight color spectrum (for the desired peak red, blue, and green colors), and the closer the color spectrum is matched to the filters, the higher the color quality. Because making perfect color filters is impractical from a cost and brightness perspective (narrow filters attenuate out-of-band photons and reduce brightness), display makers have instead focused their efforts on improving the BLU.

The problem with standard BLUs is that the LEDs used to create the backlight produce a broad spectrum of light that cannot be used efficiently by the LCD. Most white LEDs are created by coating blue LEDs made of indium gallium nitride (InGaN) with an yttrium aluminum garnet (YAG) phosphor. These two-color YAG white LEDs produce a spectrum rich in blue wavelengths with a broad yellow component, but the greens vary from cyan through lime, and the reds vary from orange to deep red. Because the filters can't stop these in-between colors, the result is poor color saturation.

Red-emitting phosphor can be added to boost color performance, but red phosphors suffer from poor conversion efficiency, wasting much of their power-generating spectrum like infrared that is not visible to the human eye. Like the yellow phosphors, red phosphors have a relatively wide full width at half maximum (FWHM) — a characterization of the width of the spectrum at which emitted radiometric power has dropped by half — so they cannot be precisely tuned to match either existing color filters or the manufacturers' peak color specifications. So the resulting white light, while offering a richer spectrum, still incurs substantial light and efficiency losses.

++++