Driverless AC-LED light engines are a convenient, economical replacement for the traditional driver plus LED configuration, and PETER SHACKLE explores a new topology that delivers significantly better flicker performance.

The solid-state lighting (SSL) community has continued to explore the possibilities of so-called AC-LED technology because such a driver circuit for an LED light engine is much simpler than the standard AC/DC driver. However, up until the present time, many specifiers have been reluctant to use AC or driverless light engines because the light was characterized by a flicker index around 0.32. In this article, we will present a new approach to AC-LED light engines that use higher frequencies to deliver a flicker index of 0.15 simultaneously combined with a power factor of 0.9.

Interested in more articles & announcements on LED light engines?

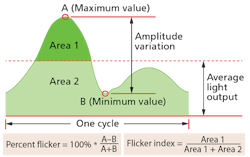

Flicker index is a concept that has been around since 1952, and its companion concept percentage flicker was first defined in the year 2000. The IES (Illuminating Engineering Society) handbook published the graph shown in Fig. 1, which defines both of these concepts. Flicker first came to public attention in the 1970s when a correlation was found between the flicker present in magnetic ballasted fluorescent lights and the headaches and eye strain suffered by a small percentage of mostly office workers who worked in the presence of these lights. Following this recognition, magnetic ballasted fluorescent lights were gradually replaced by high-frequency electronic ballasted fluorescent lights throughout the 1990s and the complaints of headache and eye strain ceased.

FIG. 1. The IES defined flicker index and percentage flicker metrics based on this graph.

Flicker challenge

Fast-forward now to 2015, and LED lamps and luminaires are finding widespread use. There have been flicker issues across a broad range of SSL products for general illumination, including poorly designed products that use AC/DC drivers. Still, the AC-LED technology is our focus here because flicker is one of a few issues that are gating more widespread adoption of the technology, which otherwise may prove more cost effective and reliable compared to AC/DC designs.

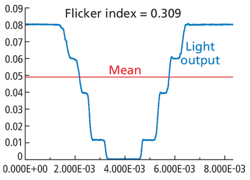

Fig. 2 shows the light output profile of a conventional 2015 driverless AC light engine. The flicker index is 0.309 and the percent flicker is 100%, which simply reflects the fact that at certain points during the line power cycle the instantaneous light output goes through zero. For comparison, the light output profile of a typical halogen replacement lamp using LEDs has a flicker index of 0.105.

Michael Poplawski and Naomi Miller of the US Department of Energy (DOE) Pacific Northwest National Laboratory (PNNL) documented the light output profiles for a number of light sources in a 2011 presentation at an IES conference. These waveforms give a feel for what typical instantaneous light waveforms look like, and their associated flicker index numbers.

Acknowledging frequency

Both of the standard measures of flicker index and percentage flicker have a weakness in that they do not take into account the frequency sensitivity of the human eye. In 1988, Sam Berman and others had some heroic volunteers have electrodes attached to their eyes in order to pick up the electrical impulses resulting from high-frequency light pulses as they went to the brain through the optic nerve. The results showed that the sensitivity decreases rapidly with increasing frequency, being down by roughly 1000× by a frequency of 200 Hz and not being recorded for higher frequencies. For this reason, suggestions have sometimes been made that to represent what the eye perceives, all frequencies above 200 Hz should be filtered out.

FIG. 2. Typical AC-LED light engines have had a relatively high flicker index.

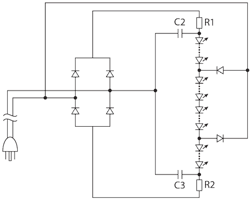

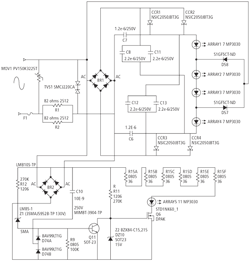

FIG. 3. The circuit represents a fourth-generation AC-LED light engine.Source: Segue Electronics.

In 2015, the Lighting Research Center (LRC) at Rensselaer Polytechnic Institute described a flicker metric that reflects the sensitivity of the human eye, based on the frequencies that 50% of subjects could perceive. However, prior research by E.M. Jaen in 2011 had shown that human visual performance is degraded by the presence of high-frequency flicker even when the subjects involved were not capable of perceiving the flicker directly.

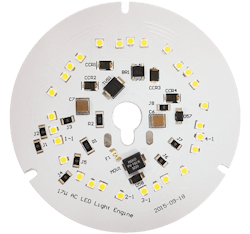

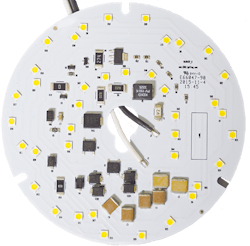

FIG. 4. The circuit from Fig. 3 was implemented in this modular product by Segue Electronics.

A consistent picture emerges here. Half of human beings cannot perceive flicker above 60 Hz as documented by the LRC, yet the work of Berman shows that frequencies up to 200 Hz are indeed being transmitted to the brain, and Jaen confirms that visual performance is degraded even when subjects cannot perceive the flicker. The 200-Hz limit corresponds to a frequency having a time period of 5 msec (milliseconds), which makes the point that a gap in a waveform on the order of, say, 2 msec or less will be imperceptible because the human eye cannot detect and signal the existence of such fast events. This knowledge can serve as the basis of a circuit that achieves simultaneously low flicker index and high power factor.

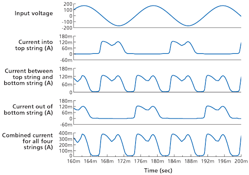

FIG. 5. A graph of current through the LED strings relative to line voltage shows short gaps in light output.

New driverless topology

Last year, we had described what we considered to be a fourth generation of driverless AC-LED light engines. That circuit is shown in Fig. 3. The circuit achieves a power factor greater than 0.7 - suitable for Energy Star consumer applications - and a flicker index of 0.28, which was at the time better than any AC-LED light engine available. Fig. 4 shows an example of a light engine made using this circuit. The resistors shown in the theoretical circuit of Fig. 3 have been replaced by current controlled resistors (CCRs) to get better voltage regulation of the light, and conventional voltage surge-protection components have been added.

This simple-looking circuit contains four identical strings of LEDs, all connected together in series. In the design simulation its electrical efficiency is 87%, although this drops slightly in real life when surge protection circuitry is added. One aspect of these light engines is that the innermost two LED strings produce light every half cycle, whereas the two outer LED strings produce light on every other half cycle.

The light output from the two outer strings comes from the top string on one half cycle and from the bottom string on the next half cycle. In order to get the light output to be blended uniformly, each LED from the topmost string is placed as close as possible to a corresponding LED from the bottommost string. This arrangement can be seen in the actual circuit shown in Fig. 4. In order to minimize the number of components, integrated LED pairs are used for each LED component instead of using discrete LEDs. Fig. 5 shows the computed current through each of the four strings plotted over time, compared to the power line voltage. It can be seen that the combined current is relatively flat, except for a 2-msec gap every half cycle.

What is intriguing about Fig. 5 is that the 2-msec gap does not happen at the line voltage zero crossing but instead just past the peak of the line voltage waveform. The 0.73 power factor comes about because there is little current drain just after the peak of the power line voltage. The flicker index is as high as 0.28 because there is no light output in this same time period just after each peak of the power line voltage. If we contrive to draw some current from the power line and pass it through LEDs during this time interval, then the power factor can be improved and the flicker index can be decreased. This concept gives birth to the commercial and industrial circuit shown in Fig. 6 - the Photalume light engine.

High PF and low flicker

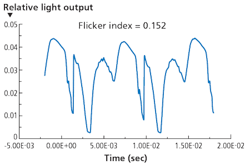

The circuit in Fig. 6 contains the consumer circuit previously described but now with the addition of a fifth string of LEDs, which comes on during the gap in the light output of the original circuit. A control circuit turns it on only when the line voltage is below a certain level and declining. The instantaneous value of the measured light output over time is shown in Fig. 7. There are two dips in light output per half cycle, one approximately for 1 msec and one with duration of less than a msec. These brief dips are imperceptible to the human eye and hence the perceived light quality is better than would be expected from the 0.152 flicker index.

FIG. 6. A newer AC-LED topology adds a fifth string of LEDs to enable more uniform light output.

A common question is how does this performance relate to the requirements of IEEE 1789-2015, a standard that makes recommendations about light flicker content? That standard is limited to sinusoidal light output fluctuations, which this waveform is very clearly not; hence IEEE 1789 does not apply to this waveform. Since the fifth string only operates for a small fraction of each cycle, it is acceptable to simply limit the LED current with resistors, which has only a minor impact on the overall efficiency.

FIG. 7. The graph of light output from the circuit in Fig. 6 shows a much lower flicker index.

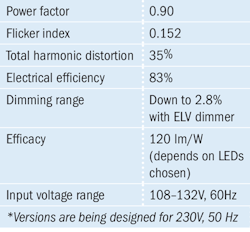

Fig. 8 shows an example of a light engine made using the commercial/industrial circuit of Fig. 6. This circuit has surge protection circuitry consisting of a metal oxide varistor (MOV), voltage dropping resistors, and a transient voltage suppressor (TVS), enabling it to withstand conventional voltage surge tests. The power lost in the voltage dropping resistors lowers the efficiency to 83%. The table shows a summary of the performance data. When running on a bench in open air, a 10W version of the light engine runs at a temperature of 60°C, reflecting its level of efficiency.

Light engine performance

An interesting property of the light output waveform of this light engine is that the modulation is at frequencies that are too high for the human eye to perceive. As previously described, a good approximation to what the human eye can perceive can be achieved by simply putting the light output through a 200-Hz low-pass filter. In this case, a 4th order Butterworth filter was used, and the percentage flicker that was nearly 100% was reduced to only 22% when the light output waveform was filtered in the way that corresponds to human eye capability.

The light output of the light engine increases with the input line voltage. A 10% increase in line voltage gives 6.4% increase in light output.

The dimming performance of the light engine is of particular interest. Since the circuit contains capacitors, albeit small ones, a so-called capacitive dimmer (otherwise known as a trailing edge dimmer, an electronic low-voltage [ELV] dimmer, or reverse phase control dimmer) must be used. In this way the product can be dimmed down to 2.8% without any instability. The flicker index increases as the dimming progresses, similar to what is observed with any AC-LED driverless light engine.

In the previously mentioned 2011 work conducted by Poplawski and Miller at PNNL, a number of AC-LED light engines were tested and it was reported that all had a flicker index of 0.42. In 2015, the best AC-LED light engines available had a flicker index of 0.32. Now, in 2016, the Photalume light engine is performing with a flicker index of 0.15. This is being achieved by storing up minute amounts of energy on chip capacitors and releasing it at just the right moment. The result of this is a driverless light engine that is flat and efficient, and combines a power factor of 0.90 with a flicker index of 0.15.

Performance data for the Photalume light engine.

For basic lighting applications, it is a good prediction that separate LED drivers are becoming increasingly unnecessary as the old-fashioned concept of LED driver plus LEDs is replaced by the driverless AC light engine. In particular, one may predict a future in which luminaires using these thin, efficient light engines might simply be placed flat on ceilings with only small wire holes, a useful convenience and cost reduction. Large-scale versions of these circuits have been designed that are suitable for high-bay lights, street lights, and other powerful applications.

FIG. 8. The circuit from Fig. 6 is captured in this modular LED light engine manufactured by ERG Lighting.

The circuits described in this article are patent pending. Licenses may be obtained from Photalume.

PETER W. SHACKLE([email protected]) is an inventor and patent consultant who works on driverless LED light engines under the business name Photalume.