SSL PROJECTS

Zumtobel illuminates new Leica facility with energy-efficient lighting

Zumtobel has announced a major solid-state lighting (SSL) project in a new headquarters facility for Leica Camera that's located in Wetzlar, Germany where the camera maker was founded. The varied lighting scheme was intended to blend seamlessly into the building while providing an optimum workspace and to highlight areas such as the art gallery and museum areas that are open to the public to serve as a monument of the company's history. The project involved Zumtobel Claris II and Linaria fluorescent products and Panos Infinity fixtures, among other products.

Perhaps the most intriguing elements of the design center around the Panos Infinity LED luminaires that were used in a variety of spaces including customer-meeting areas, public areas, corridors, and in the on-site coffeehouse. The design teams from hpi Himmen and Lichtvision deployed the recessed luminaires as downlights for general illumination and as wall washers in many areas.The fixtures deliver on the goal of blending into the interior design while delivering light on target in areas such as the museum and gallery. Moreover, the designers said the LED choice delivered 40% energy savings relative to fluorescent options.

The design relies on an innovative mix of color temperatures to ensure a comfortable visual experience. The downlights are 3000K CCT products. But the building is designed to allow a significant amount of natural light into most areas. So the designers chose to use 4000K-CCT wall washers to more precisely match the natural light.

The Leica facility lighting uses DALI (digital addressable lighting interface) fixtures to enable the control requirements. In turn, the DALI interconnects are bridged to the KNX building management system. The system is used to dim the lighting when feasible to save energy and to extinguish lighting in areas that are unoccupied.

RETROFIT LAMPS

Cree develops next-gen LED retrofit lamps with legacy looks

Cree has revealed its second-generation commercial LED bulb/lamp design with products designed to replace 40W and 60W incandescent bulbs. The new design is lower in cost with 40W-equivalent products selling for $7.97 at Home Depot, and the cost reductions are derived from an airflow-based thermal design that enables the use of fewer LEDs driven at higher current and lower-cost thermal elements. The result is a replacement LED A-lamp that is mostly indistinguishable from an incandescent bulb.

Cree has consistently been among the technology and market leaders since it entered the market with 40W- and 60W-equivalent LED lamps back in March 2013 (http://bit.ly/1u6A1XA). The company followed those products with both 75W- and 100W-equivalent A-lamps, A-lamps with high CRI, and BR30 lamps (http://bit.ly/1p2BMlK). All shared a similar internal design based on what Cree called a filament tower.

Cree has said the new design looks more conventional, but the real reason for the design is lower cost and perhaps even better optical performance, although the prior lamps have remained among the most highly rated on the market.

The original design had a notable metal heat sink painted white. That feature certainly provided a different look from incandescent bulbs, but it was not nearly as obtrusive as the silver metal heat sinks with fins used on many low-cost LED bulbs.

The mainstream media has reported that the new Cree design has no heat sink. We haven't had the chance to get a hands-on look at the product just yet, but we suspect that the new design has thermal elements and likely uses thermoplastics to minimize the look of the elements and reduce weight as well. Based on the specs, the new lamps come close to the weight of an incandescent bulb at around 2 oz.

Based on the cutaway photo that Cree supplied, the new design uses far fewer LEDs than did the filament tower. The LED lamp appears to be segmented into four sections, with the sectors being pie-like if viewed from the top of the bulb. Note that Philips and Best Buy have previously used segmented approaches, although quite different from Cree. But Philips has notably retreated from that approach in its mainstream lamps (http://bit.ly/1GxxfA2).

The new lamps offer 460- and 815-lm output in the 40W and 60W equivalents, respectively. As in the past, Cree will offer the lamps in a warm 2700K CCT and in a daylight version at 5000K. The brighter version uses 11W. CRI is 80 or better. The product is slightly larger than an A-19 bulb but would fit in most applications.

HISTORICAL BUILDINGS

Osram completes SSL retrofit of the Vatican's Sistine Chapel

Osram has announced the completion of a major SSL project, retrofitting the Sistine Chapel in Rome, Italy with LED-based fixtures. The new lighting uses 90% less energy than the prior installation and the project was backed by the European Union under the Digital Agenda for Europe initiative.

We first covered the Sistine Chapel story back about one year ago (http://bit.ly/1xpJNTW). At that time, the story was primarily focused on lighting Michelangelo's works of art. And indeed the project delivered on those goals while also providing improved ambience in the chapel. Moreover, the project far exceeded the original goal of 60% energy savings.

LED-based lighting is proving especially viable in such settings. For example, Philips lit all of the precious works in the Rijksmuseum in Amsterdam, Netherlands with LED-based fixtures (http://bit.ly/Ls8HzB). We also recently covered an application where LEDs were used in an iconic religious facility, lighting the St. Mary and Bartholomew Church in Harsefeld, Germany (http://bit.ly/1tQsfkJ).

The Sistine Chapel lighting project consumed more than 7000 LEDs from Osram Opto Semiconductors installed in custom fixtures designed for the high-profile project. Light levels are higher but controlled, and visitors will enjoy the experience with enhanced viewing of the famed frescoes.

Osram believes that the work breaks new ground. "Osram has developed an LED lighting solution that sets standards in terms of technological strength, quality, and innovation," said Klaus Patzak, Osram's CFO and the executive in charge of luminaires at the company. "It's the first such solution in the world and paves the way for completely new possibilities for our clients. We will now rapidly turn this potential into reality."

But the curators of the property are perhaps even more enamored with the results. "The Sistine Chapel contains the most extraordinary works ever conceived by the human mind and is Michelangelo's masterpiece," said Antonio Paolucci, director of the Vatican Museums. "We want to honor the 450th anniversary of Michelangelo's death by providing new lighting for his work."

AUTOMOTIVE

TI enables adaptive LED headlamp designs with matrix manager IC

Texas Instruments (TI) has announced the TPS92661-Qi LED Matrix Manager for automotive headlamp systems. The IC integrates 12 MOSFET switches that are used to steer current through or around multiple LED strings to vary beam patterns and intensity in intelligent and adaptive headlamp systems.

The most widely known implementation of an intelligent and adaptive headlamp system is the Audi Matrix unit announced last year (http://bit.ly/1qtZK7k). The system can steer a beam to match corners in the roadway and create notches in the beam to ensure that the beams don't blind drivers of oncoming vehicles. Effectively the technology eliminates the need for a low beam. The system is on production cars in Europe, although for now US standards prohibit such implementations (http://bit.ly/1xpXhyV).

Coincidentally or not, TI chose to use the word "matrix" in the branding of its new IC. The switch array is designed to drive a matrix of LEDs, both switching strings on and off and dimming strings to deliver the adaptive headlamp features. The company said the IC would reduce the printed-circuit board (PCB) size by 73% in an adaptive headlamp controller.

The IC can drive as many as 96 individual LEDs broken into 12 strings. Each string can be individually controlled including pulse-width modulation (PWM) dimming with 10-bit precision. It meets the AEC-Q100 Grade 1 specification for automotive-qualified components and is designed to work with a master microcontroller (MCU) to enable the matrix headlamp functionality.

Osram Opto demonstrates single-LED low-beam headlamp in lab

Osram Opto Semiconductors has revealed a laboratory development of a single LED that delivers 1400 lm and that, combined with a reflector, can implement an automotive low-beam headlamp function that meets relevant global standards. The company believes that in the next two years a module smaller than a box of matches will be all that is required for a capable low-beam implementation.

The laboratory work combines a number of technologies in the LED manufacturing process ranging from epitaxy to phosphor conversion to perhaps most significantly packaging. The new LEDs are based on Osram's UX:3 chip technology. UX:3 is a thin-film flip-chip process that results in the contacts being on the bottom of the die (http://bit.ly/1u77S2A). After epitaxy, the die is flipped with the light emerging from what was the gallium-nitride (GaN) layer that was originally adjacent to the substrate.

The company also uses a ceramic-based phosphor for the headlamp LEDs, and that phosphor is more capable of delivering consistent lumen output over long life, especially in adverse thermal environments. To help mitigate thermal issues, Osram adapted some packaging technology originally developed for the high-output Osram Ostar LEDs used in projector applications (http://bit.ly/1snA799). With the contacts on the bottom of the LED, the component can be soldered directly to copper in the package.

The result is an LED that outputs 200 Mcd/m2 (mega candela per square meter). The company said the LED offers triple the luminance of existing LEDs targeting the auto application. Moreover, the company has tested the LEDs at an elevated 85°C operating temperature where lumen depreciation is less than 10%. The result is potentially a low-beam module measuring only 30×50 mm.

LIGHT ENGINES/MODULES

LG Innotek develops AC-LED light engines for downlights

LG Innotek has announced plans to enter the market for direct-AC-driven LED technology. The company said it will deliver five new packaged LED products that are optimized for use in AC-driven systems. Moreover, the company is planning three families of modular light engines that combine the LED with AC-driver technology on a circuit board.

The area of AC-driver technology is a popular one at the moment because the technology can eliminate the bulky and expensive AC-DC driver module used in most LED luminaires. The downside to AC-LED technology has been lower efficacy, flicker, and less-effective dimming control. The latest products are attacking those areas of weakness, such as the third-generation Acrich3 driver IC announced recently by Seoul Semiconductor (http://bit.ly/1mkOBIi). Moreover, even driver IC specialists such as TI are offering ICs for AC-driver topologies (http://bit.ly/XEhdlI).

Apparently, LG Innotek has developed its own AC-drive technology, although the company did not provide details of the implementation in its recent announcement. The company simply said it had developed a way to control LED drive current directly from the AC line and that the implementation would deliver a 30% cost reduction relative to similar DC-driven light engines.

LG said it is offering the 5250HV (High Voltage), 3030HV, and 5630HV products for use in AC applications. The company targets the larger packages at luminaires and the 3030HV at retrofit lamps. LG claims that the 5630HV offers an industry-leading 136-lm/W efficacy in terms of LEDs designed for AC applications.

All of the new module offerings, both modules for SSL retrofit lamps and luminaires, are designed to predominantly deliver light in one direction for applications such as downlighting. The pictured light engine would most likely be deployed in a directional retrofit lamp.

Philips Lumileds announces board-level modular LED light engines

Philips Lumileds has announced the Matrix Platform including the Luxeon XR and XF family of modular LED light engines that consist of LEDs mounted on rigid or flexible printed-circuit boards (PCBs) as a building-block product for SSL developers. Lumileds, and others in the SSL industry, refer to such PCB-based products as Level 2 products differentiating the customer engagement from Level 1 products or individual packaged LEDs. The initial Luxeon Matrix products target troffers and other linear applications.

Packaged LEDs are increasingly difficult for some lighting manufacturers to work with at the component level. Both mid-power LEDs and high-power devices in flip-chip or chip-scale packages (CSPs) require automated assembly on high-end surface-mount device (SMD) production lines. Indeed, when Lumileds first pioneered the CSP LED last year (http://bit.ly/1foX4lz), the company said many customers would buy products that use the LED in a Level 2 engagement with the LEDs already mounted on a PCB, thereby simplifying both the product development and manufacturing processes.

The initial Matrix press release covered specifically the off-the-shelf XR flexible strip and XF rigid board families that use Lumileds mid-power Luxeon 3535 LEDs (http://bit.ly/1xhEk3h). In the long term, it may be flexibility in configurations of the modules that will be most valuable to lighting product developers. Lumileds has emphasized that it will offer custom options in terms of LED types and form factor.

SSL PROJECTS

Insta Elektro announces LED-based arcade lighting project

In Kiel, Germany Insta Elektro has supplied LED-based fixtures for the lighting of the Arkaden-Die Holtenauer shopping area along both sides of Holtenauer Strasse.

The Kiel project was driven by the Die Holtenauer advertising association to relight Holtenauer Strasse with special attention paid to the many shops lining both sides of the street. Moreover, the project required that the lighting be integral with the residential units behind the shops on each side. The concept sought to make the shops, and their glass roofs, a seamless part of the neighborhood architecture.

Architectural firm Kersig von Hanneken Architekten, designer Studio DL, and contractor Elektro Lübke partnered on the project. Ultimately, the plan centered on using the recessed windows along the top of the residential building to conceal RGB (red, green, blue) color SSL fixtures that could directionally project light onto the arcade and the glass roofs. Additionally, the group installed 200m of linear white LED lighting to highlight the striking white glass roof on the west side of the street.

The products installed include Ledlux luminaires, Instalight lighting control systems, and Ledtrix DMX-based interconnect products. Indeed, the installation allows for dynamic light scenes tuned to events, the calendar, or the whims of the arcade.

Insta continues to be involved in innovative LED lighting projects. For example, last year the company supported a project at the Wanne-Eickel, Germany bus station and town square in which the luminaires were installed in the pavement (http://bit.ly/1tQIhuZ). More recently, the company supplied an energy and ecology exhibition with customized RGB luminaires (http://bit.ly/1xdpQAp).

Race engine manufacturer installs LED lighting in California shop

LEDtronics has announced an LED-based high-bay lighting project at the Ed Pink Racing Engines shop in Van Nuys, CA. RTM Lighting & Electronics handled the installation that is generating brighter light levels for employees while reducing energy usage by 70%.

The race shop is renowned in US motorsports having built engines that won races in top series including NASCAR, IndyCar, and top-level dragsters. The engine shop has worked with racing teams from Ford, Pontiac, and Toyota and supported superstar drivers including Tony Stewart and Don Prudhomme. But the shop's former lighting was hampering the precise work of the staff and wasting significant energy, leading to a major retrofit. "The lighting is much better for our unique work environment," says general manager Frank Honsowetz, former director of racing for Nissan North America who joined Ed Pink in 2001, about the upgrade.

The facility consists of two buildings totaling 12,000 ft2. Previously, a mix of T8 and T12 fluorescent fixtures lit the facility where engines are rebuilt, built, tested, and designed for an international customer base. The upgrade allowed the shop to use fewer HBL003-200W-XPW-101WD LED high-bay luminaires from LEDtronics. "Using a total of only 2600W, the LED lights saved the company 5730W," said Mark Jarel, LEDtronics street & outdoor lighting product sales manager.

"We are saving about $900 a month from the conversion to LED lighting," said Pink Racing's Honsowetz. "At this rate, we will pay for the conversion in about 13 months."

Still, Honsowetz noted other benefits of the upgrade beyond the energy savings and lighting quality. "With LED lighting, the interior temperature on hot days is easier to control."

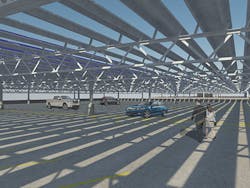

MSP airport to combine LED lighting and solar generation on garages

The Metropolitan Airports Commission operates seven airports in the Minnesota Twin Cities area of Minneapolis-St. Paul, and has begun a massive energy-efficiency project including LED lighting at the flagship Minneapolis St. Paul International Airport (MSP). Construction was begun in early fall on what the agency said is Minnesota's largest solar generation project - a 3-MW plant located atop two parking structures (see rendering of the solar array atop Terminal 1's parking ramp here). Moreover, the project will include retrofit of more than 7700 metal-halide fixtures to SSL products.

"The Metropolitan Airports Commission has worked for decades to operate Minneapolis-St. Paul International Airport as sustainably as possible, investing millions in infrastructure to reduce impacts to soil, water, and air quality, and spending nearly a half-billion dollars on noise mitigation around MSP," said Jeff Hamiel, the Commission's executive director and CEO. "This ambitious new solar energy project will create jobs, reduce the airport's carbon footprint, and save the Airports Commission hundreds of thousands of dollars a year. I want to thank all the public and private entities who have worked with us to make this project possible."

We've seen an uptick in projects that combine LED and solar technology. Indeed, we covered a presentation at the February Strategies in Light conference that made the point that energy-efficient LED lighting was making solar generation more viable despite the inherently low efficiency in solar panels (http://bit.ly/1kXzh1e).

The project addresses many angles in energy efficiency. For example, the airport will add 18 charging stations for electric vehicles. Moreover, the airport expects the solar plant to deliver 20% of the airport's energy needs.

The energy services company Ameresco has been selected to lead the $25.4 million project. A number of Minnesota-based organizations will participate including tenKsolar, Thrivent Financial, and Hunt Electric. Apparently Cooper Lighting will supply the SSL fixtures as they were the only lighting company listed as a participant. Utility Xcel Energy is contributing a $2 million grant to the project from its Renewable Development Fund.