LED device manufacturers have to be commended for their persistence in improving white LED performance over the last decade. The year 2007 may be when LEDs began to seriously take on traditional light sources in general lighting applications. Downlighting and street/parking lot lighting are two applications for which several manufacturers have released LED products to compete with traditional lighting.

However, as with many traditional luminaires, not all LED-based luminaires provide reliable performance. While the LED itself may have good quality and performance as a bare device, its integration into a luminaire and that luminaire’s installation environment are key to the final product performance and whether it will stand up to customer expectations. Luminaires that do not meet customer expectations can turn off users from promising LED technology.

So, the questions become:

- How do we differentiate product performance in terms of life and light output?

- How can we keep the market transformation of LED technology from facing early setbacks?

The answers to these questions may rest upon changing the tradition of photometry as we know it today.

Traditional testing

Those knowledgeable in lighting use photometric data to select and use suitable luminaires. Traditionally, photometric testing of light sources and luminaires is performed at an ambient temperature of 25°C. This temperature typically is measured at a position up to 1 meter away from the light source or luminaire and at the same height as the midpoint of the light source or luminaire (e.g. IESNA LM-9-99; "IESNA Approved Method for the Electrical and Photometric Measurements of Fluorescent Lamps" published 1999 by the Illuminating Engineering Society of North America).

Photometric data collected according to such testing standards have been useful for selecting and specifying technologies, such as incandescent, whose performances are not affected by the ambient temperature surrounding the light source. However, such data are not very useful for LED technologies, which can show radically different photometric performance and life when used in different application environments. Selecting LED downlights for an application on the basis of published photometric data could result in considerably lower light levels in the space than designed, leading to disappointment.

Temperature affects LEDs

In an LED, the temperature of the junction between the semiconductor’s light-producing layers (p and n materials) is known to be good predictor of performance. The junction temperature depends on the drive current supplied to the LED and the application environment where the light source or luminaire is installed.

Usually, a lighting system can experience different thermal environments depending on where it is installed in the application. To obtain realistic performance data for a lighting system, the test environment must mimic the actual environment where the luminaire would be used. To address this concern, in 2006 researchers at Rensselaer Polytechnic Institute’s Lighting Research Center (LRC), together with sponsors of the Alliance for Solid-State Illumination Systems and Technologies (ASSIST), recommended the creation of three environmental conditions to test the performance of directional lighting systems (e.g., downlights and track heads) that are applicable to any light source and address the specific concerns of LED systems.

These recommended testing conditions were based on the typical operating environments of indoor lighting systems. These testing conditions were described and published in ASSIST recommends. . . Recommendations for testing and evaluating luminaires used in directional lighting, which is available on the LRC website.

Test environments

The test environments proposed by the LRC and ASSIST are open air, semi-ventilated, and enclosed. In the case of open air, the light source and the current driver have plenty of ventilation around them for convection heat transfer. Convection heat transfer is important for LEDs because they do not radiate heat out from the source like incandescent lamps do. The open-air testing condition is most similar to the traditional photometric testing environment.

In the next environment, semi-ventilated, the light source and the driver have limited ventilation around them for convection heat transfer. In enclosed environments, the light source and the driver have almost no ventilation around them for convection heat transfer. As an example, in practice these three environments can be thought of as luminaires operating in a suspended track lighting system, as recessed downlights in non-insulated ceilings, and as recessed downlights in insulated ceilings, respectively. (See endnote 1 - "Recommended luminaire testing environments" for more information.)

In general, the three testing environments and recommended test methods published in "ASSIST recommends" were designed to:

-- Provide more useful information for selecting and using LED directional lighting

-- Help differentiate between good and poor performing LED luminaires in terms of light output and life

-- Simplifiy and improve photometric data accuracy by controlling the board temperature of LED luminaires with a smaller volume test chamber instead of controlling the ambient temperature of the room while gathering data.

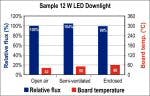

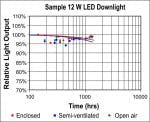

To understand more clearly how LED luminaire performance varies under the three environmental conditions, the LRC began testing commercial LED downlight luminaires according to ASSIST’s recommendations. The LED downlights selected for testing were IC-rated. These luminaires were mounted and operated in the three different testing environments (open air, semi-ventilated, and enclosed) per ASSIST recommends.

Testing methodology

A temperature sensor was attached to the LED circuit board of each downlight to measure the board temperature of the luminaires while operating in the testing environments. After an initial 100-hour seasoning period, the LED downlights were turned on and allowed to stabilize for 24 hours. The board temperature values for the three testing environments were then measured to obtain baseline temperature data for the luminaires. From the board temperature, the LED junction temperature could be estimated.

Next, the LED downlights were mounted inside a specially designed heated chamber that maintained the same board temperatures found previously. The board temperatures were monitored and maintained throughout the test period via a feedback control circuit that provided a signal to a supplemental heater built inside the chamber. This procedure ensured that the LED junction temperature remained equal to what it would be if the LED downlights were mounted in an actual application.

An integrating sphere with an optical spectrometer attached to one of the ports was placed below the LED system, as shown in the photo of the downlight test rack (Figure 1). Light output from the LED downlights entered the integrating sphere through an entrance port large enough to accept most of the flux. At regular intervals, the integrating sphere was positioned under each of the LED downlights and measurements were taken for light output and spectrum.

The use of the integrating sphere ensured good mixing of light output to obtain average values for flux and color. Generally, the spatial distribution of light level and color of an LED luminaire beam is non-uniform and therefore can lead to large measurement errors if the detector sees only a portion of the beam.

Test results

Lifetime results

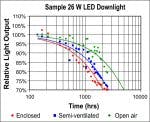

ASSIST defines LED life by the time, in hours, that it takes for a light source or system to reach 70% of its initial light output (L70). (For more information about ASSIST’s definition of LED life, see http://www.lrc.rpi.edu/programs/solidstate/assist/ledlife.asp.)

In terms of expected life for the 26-watt LED downlight (figure 3a), even though the number of hours for data collection is still very low, extrapolated data indicate that this downlight will reach its end of life, L70, within 2100 hours for an enclosed application, 2650 hours for a semi-ventilated application, and 5000 hours if placed in open air with plenty of ventilation.

Outcomes

To illustrate the point, if one were looking for a 600-lumen downlight luminaire for a residential application with insulated ceilings, both luminaires considered here would have qualified based on their published photometric data, measured according to traditional practice. However, the 26-watt downlight product would have led to disappointment on two fronts, initially with a 30% lower light level in the space and in the longer term with frequent replacement due to a much shorter life than advertised.

The testing data reported here illustrate why photometric data produced according to traditional testing standards are not very useful for LED luminaires. LEDs have great potential to provide customized, dynamic, and energy-saving illumination—if the technology can be presented using relevant and meaningful photometric data and installed in optimal applications.

Changing traditions by testing and reporting data per ASSIST recommends will assist end-users in selecting appropriate LED luminaires by providing more useful information. In turn, this can help set the right expectations and ultimately lead LED technology to widespread acceptance and use.

Endnote 1 - Recommended luminaire testing environments

The three recommended testing environments described cover the typical indoor applications of directional lighting. These conditions provide a range that allows users to estimate the performance of a downlight in any application condition if the specific operating board temperature is known. If a particular application falls outside of the temperature range of the three recommended environments, the same principle for testing can be applied:

1) Install the luminaire in a way that is representative of the actual application

2) Allow the light source to stabilize and measure the board temperature (for LEDs) or other point known to have a direct relationship with the performance of the light source (e.g. the cold spot for fluorescent lamps)

3) Test the luminaire photometrically and electrically at the same board temperature found in the previous step

One of the advantages of the three testing environments as described by ASSIST recommends is the use of small testing chambers to control more precisely the temperature, as opposed to controlling the room’s ambient temperature as is typically done with traditional photometry. Additionally, the point where the temperature is monitored is defined unequivocally because of its location within the luminaire rather than in the ambient environment.

Endnote 2 - Alliance for Solid-State Illumination Systems and Technologies (ASSIST)

ASSIST was established in 2002 by the Lighting Research Center (LRC) at Rensselaer Polytechnic Institute, Troy, NY as a collaboration between academic researchers, manufacturers, and government organizations, ASSIST’s goal is to facilitate the broad adoption and effective use of reliable, energy-efficient solid-state lighting and to speed its market acceptance. ASSIST is active in a number of research projects and other activities to advance and promote LED technology. Research, education, and industry collaboration have been the key activities of the program, which seeks to reduce many of the technical hurdles standing between LEDs and their market acceptance.

As part of these activities, ASSIST has developed a publication program called ASSIST recommends to provide a set of formal recommendations to the LED and lighting communities about issues important for the reliable performance of LED lighting and its comparison to other light source technologies. The publications include recommendations for LED life definition, testing and measurement, best practice guides for different lighting applications, and recommendations for selecting LED lighting. These publications are developed under the guidance of ASSIST sponsors using research conducted by the LRC.

Each ASSIST recommends publication undergoes internal review, first by LRC researchers and then by ASSIST sponsors. Industry input also is gathered during the writing process through one or more roundtable sessions hosted by ASSIST and the LRC. Based upon this industry input, the publications are revised and then published electronically for free download (ASSIST recommends). As warranted, the publications are updated from time to time to reflect new research, technologies, methods, and equipment.

ASSIST recommends is sponsored by Cree; Federal Aviation Administration (FAA); Lite-On; GE Lumination (formerly GELcore); New York State Energy Research and Development Authority (NYSERDA); Northwest Energy Efficiency Alliance; Osram Sylvania; Philips Lighting/Color Kinetics, now Philips Solid-State Lighting Solutions; Photonics Cluster (UK)/The Lighting Association; Seoul Semiconductor; and the U.S. Environmental Protection Agency (EPA).