It’s long been known that lighting control systems are sad underachievers. Some people even fear that absent energy code requirements (and utility subsidies), few buildings would even install the advanced lighting controls coming to market today. Nevertheless, advanced, that is, connected or networked, controls represent a crucial — if unfinished — set of tools in our fight to reduce energy use and improve the responsiveness of lighting to building occupants.

Where’s the problem? Do we need advanced technologies or simply better techniques for using what we have? Of course, this is a false dichotomy; we need to improve both technology and technique, and — equally important — we need a holistic approach to getting it done. The Next Generation Lighting Systems (NGLS program) is trying to do just that.

The NGLS Program

NGLS is a program of the US Department of Energy (DOE), co-sponsored by the Illuminating Engineering Society (IES) and the International Association of Lighting Designers (IALD) and managed by Pacific Northwest National Laboratory (PNNL). NGLS is part of a broad DOE/PNNL effort to advance the effectiveness of lighting controls. The NGLS program primarily focuses on configuration complexity and uses observational research in “living lab” environments.

“Living lab” is a catchy phrase, but what does it really mean? At NGLS, we see our living labs (we have two currently in operation) bringing together several key parameters. Not only do the labs focus on the intersection of technology and its implementation, but they maintain ongoing, dynamic installations. These are upgraded, renewed, and expanded over several years. The labs engage multiple constituents, including manufacturers, owners, users, and design and construction participants, who follow rigorous installation, configuration, operation, and evaluation protocols. The installations at living labs provide both quantitative and observational research results, while operating with the guidance of diverse teams of designers, engineers, utility consultants, and others drawn from the lighting profession.

At the living labs, the teams aim to provide robust input to those who make the products and those who use them, with the goal of improving the human and energy performance of the next generation of lighting systems. This is achieved via in-depth observational research.

Observational research witnesses the interaction of products and people and of technology and technique. Using detailed protocols to collect and assess feedback, we observe, document, and measure how systems are installed and configured, how well they perform, and how users operate them. Our goal is to remove barriers to the configuration complexity challenges faced by most lighting projects in the field.

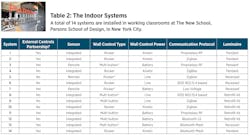

The NGLS evaluation teams consist of experienced industry professionals drawn from a wide range of practice. We currently have two living labs in place — an interior lab at Parsons, The New School, in New York City and an exterior lab at Virginia Polytechnic University, in Blacksburg, VA.

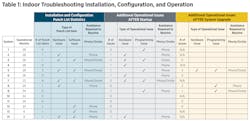

Lessons learned — Inside

As our first phase of research, we selected 14 different systems marketed as “easy to install and configure,” and installed each one in its own classroom at Parsons. The systems consist of luminaires (troffers, linear pendants, retrofit kits) and connected (i.e., networked) wireless controls (mostly with sensors integrated in each luminaire). We now have a rich base of observational and measured data gathered over the last three years. Here we will focus on four of our most important findings.

“Easy ain’t that easy.” That’s the headline, but the more nuanced finding is that for the small-to-mid size market, especially retrofit applications, “simplicity

works.” To a remarkable degree, the simplest systems installed more easily, configured more reliably, and operated more intuitively than those with more functionality and complexity.

Communication matters! Success in installation, configuration, and operation benefits critically from good communication. This is all-encompassing and includes complete specifications, clear installation and configuration instructions, coordinated job-site teamwork, readily available tech support, and intuitive labeling. If there is one area with the opportunity for rapid improvement, it’s communication.

Diversity is a challenge. We have yet to see products coalesce around common forms, configuration methods, or even wall controls. The lack of commonality slows learning, adoption, and — presumably — economy.

Do the systems really work and perform to specification? Light levels and manual dimming are easy to measure (and most systems succeeded in those regards). Verifying vacancy operation and daylight harvesting takes more and careful evaluation, and the results have been so-so. This is more than a question of return on investment and code compliance; our nation needs the energy-saving technology to provide low-cost, resilient energy reductions.

Importantly, the living lab lives. We have additional indoor systems planned for installation and evaluation in classrooms, similar to our initial efforts. Following the single-room evaluations, we will expand evaluations to include current successful systems, each in a larger and more diverse footprint, testing their ability to perform in more-demanding applications.

Lessons Learned — Outside

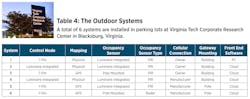

For the exterior lab, we are focusing on connected systems with presence (motion) detection (both luminaire-integrated and remote sensors). Unlike our indoor sensor evaluation, the outdoor test requires that lights return from dimmed to full output when motion is detected. Six different systems are installed on existing 30-ft poles in parking lots around Virginia Tech research facilities. Four important takeaways are somewhat similar to what we’ve found with the interior systems at Parsons.

Connectivity works...but it takes a lot of effort! Five of the systems now enjoy wireless control, including dimming, scheduling, and reporting. However, the labor hours expended, and the number of days required to reach this point, can best be described as “appalling.”

Connected lighting in outdoor applications is no place for non-specialists. Every system required onsite support from factory personnel.

Presence detection in the retrofitted parking lots hasn’t worked so far. The passive infrared (PIR) sensors used in the outdoor installations consistently failed to raise dimmed light levels in the presence of moving vehicles and pedestrians. This may be caused by inadequate sensor sensitivity, or latency of response, or a combination of both. The failure to detect moving vehicles until well past the sensor raises questions of safety. And the failure to detect pedestrians leaving the buildings or entering the drive lanes challenges both the reality and the perception of personal security. Lacking reliable sensor performance, there may well be anxiety about using deeply dimmed lighting when activity, though intermittent, is still present. What seems clear is the need for improved technology.

As we found in interior application, there is no consistency among these outside systems. The lack of consistency goes well beyond the technology and, importantly, includes the front-end interface for property managers and installation and configuration instructions for installers.

How should we use this data?

Of course, recommendations from these living labs depend to an important degree on whether you are buying or selling, using or providing the requisite lighting hardware and controls. There are a few distinctions between the approaches.

For owners and their consultants, we recommend defining system objectives and priorities, then stick to the “gotta haves” and dismiss the “nice to haves.” Reliable partners, such as manufacturers, responsive sales and service channels, and installers, are necessary. And recognize the value of their time and expertise; pay what is required to get it right. Otherwise, your investment may sit idle.

For manufacturers and their sales and distribution channels, we advise marketing products candidly and clearly in terms of their capabilities. Ensure that you can provide rapid and reliable troubleshooting support (which is also good marketing), and work with installers and users upfront to improve product design and communication.

Get to know our experts

RUTH TAYLOR is project manager on the Advanced Lighting Team at Pacific Northwest National Laboratory (PNNL), where she manages the Next Generation Lighting Systems evaluations and contributes to several other projects focused on the application and development of solid-state lighting. DAN BLITZER is principal at The Practical Lighting Workshop, a consultancy for marketing, education, and the broad dissemination of lighting and technology. He serves on the Steering Committee for the Next Generation Lighting Systems evaluations, as well as on the boards of The Designers Lighting Forum of New York and the Nuckolls Fund for Lighting Education.

*This article has been expanded from its original publication in the June 2020 issue of LEDs Magazine.

For up-to-the-minute LED and SSL updates, why not follow us on Twitter? You’ll find curated content and commentary, as well as information on industry events, webcasts, and surveys on our LinkedIn Company Page and our Facebook page.

![An installer uses a cell phone to configure a connected lighting system in a Next Generation Lighting Systems (NGLS) living lab. [Photo credit: Image courtesy of Pacific Northwest National Laboratory (PNNL) and NGLS.] An installer uses a cell phone to configure a connected lighting system in a Next Generation Lighting Systems (NGLS) living lab. [Photo credit: Image courtesy of Pacific Northwest National Laboratory (PNNL) and NGLS.]](https://img.ledsmagazine.com/files/base/ebm/leds/image/2020/06/NGLS_Photo_2.5ed693de53fa2.png?auto=format,compress&fit=max&q=45&w=250&width=250)