Osram Opto Semiconductors used LightFair International (LFI) to debut the Osconiq S 3030 QD mid-power LEDs with the QD suffix referring to the fact that the LEDs rely on quantum dots to deliver a narrow energy peak in the red spectral region. The quantum dot technology enables the LEDs to deliver 173-lm/W efficacy in warm-white CCT with 90-CRI color rendering, whereas typical warm-white LEDs in the same class might deliver efficacy in the 140–150 lm/W range. Osram said at LFI that the new LEDs are available now.

Quantum dots have long promised improved light quality relative to energy efficiency, especially at warm CCTs. But the material scientists working on the technology have struggled to deliver the requisite reliability and lifetime for general lighting applications. Osram said the new Osconiq LEDs use an encapsulation process for the quantum dots that enables LED lifetime on par with phosphor-based LEDs, and we will discuss that process in more detail shortly.

The advantage of quantum dots comes via the fact that the material offers a much more narrow emission band than does phosphor. For warm-white, high-CRI output, LED makers must use a phosphor formulation rich with red phosphor. That formulation results in substantial long-wavelength red energy produced beyond the human visual range. Using red quantum dots allows Osram to minimize the wasted energy.

The quantum dot technology used by Osram comes via Pacific Light Technologies (PLT), a company Osram acquired in March 2018. PLT was a startup focused on quantum dots for both display backlighting and general illumination. The company began to find success in backlighting back in 2013 as we covered in a feature article. But the backlighting application was simpler in that the quantum dot material is sealed between film layers of the display unit that provided protection of the materials, enabling long lifetime.

The promise of quantum dot technology for general illumination goes all the way back to 2005. We first covered Osram’s interest in the technology in 2015.

Clearly, it was not an easy task to deliver on the long lifetime. At LFI, Osram showed a simplified graphic that summarized the encapsulation process involving nanometer-scale particles that Osram characterized as 10,000 times smaller than the diameter of a human hair. Despite having the word “dot” in the name of the particles, each quantum dot is composed of many smaller particles. Ultimately, the Osram quantum-dot structure has a sphere of the red-emitting particles at the core of each quantum dot with a protective layer of particles surrounding the core, forming a larger sphere.

Successfully manufacturing that structure is difficult for many reasons. Light from a blue-pump LED must pass through the outer layer and be efficiently retransmitted back through the outer layer as red energy. Moreover, the material scheme had to be developed in a way that none of the particles absorbed the photons. Efficient light extraction is a requisite for the technology to work.

Creating the encapsulation layer at the quantum dot level is ultimately the enabler for cost-effective manufacturing of LEDs. With the core protected, the dots can be mixed with phosphor and the LEDs can be manufactured using the same equipment and systems in place for making other phosphor-converted LEDs.

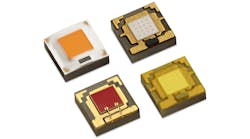

Ultimately, the 30×30-mm LEDs deliver the aforementioned 173 lm/W at a 3000K CCT. The LEDs are being sold with a minimum CRI of 90. Applications that don’t need color rendering at that level would likely be better served from a cost perspective by other LED models. Osram will offer the LEDs across a range of CCTs from 2700–6500K.

It’s also clear from the LFI demonstration that there is considerable upside in efficacy remaining as quantum dot technology matures. When we saw the spectral power distribution (SPD) graph of the new LEDs, we noted that there was still considerable energy outside the human visual range. When asked why that was the case, Osram said that they are limited in terms of how much of the quantum dot material can be used in an LED. The limit is due to the fact that the dots are cadmium-based and global RoHS (Restriction of Hazardous Substances) guidelines regulate the amount of cadmium that can be utilized.

For now, Osram is mixing some red phosphor along with the quantum dots into the composite phosphor formulation. But there is considerable work being done on cadmium-free quantum dots that would eventually eliminate the red phosphor and further extend efficacy.