ALEXANDER WILM explains how the packaged LED industry could deliver improved color consistency in SSL products by changing the component binning methodology.

LEDs have become firmly established as relevant light sources for general illumination. Their costs are now at such a low level that they can be used in any application without any problems. In terms of efficiency they already outperform all previous light sources. There is still potential for improvement, however, in the quality of light produced by LEDs. One area ripe for improvement is color rendering and above all color consistency. One way to address color consistency would be to change the LED binning methodology to use the International Commission on Illumination (CIE) 2015 10° color space. The CIE recently developed the 10° binning to guarantee hitherto unprecedented color consistency for white LEDs.

Interested in articles & announcements on packaged LEDs & solid-state lighting design?

Up to now, the standard international color space for general lighting and other applications has been CIE 1931 2°. It was published by the CIE way back in 1931 - as the name indicates. It's fair to say that the lighting industry has seen some changes since then. At the time, the incandescent lamp was the only electric light source, and that was joined later by the halogen lamp, the compact fluorescent lamp (CFL), and the high-intensity discharge (HID) lamp. Then came LEDs and LED retrofits - and finally the incandescent lamp was withdrawn for reasons of energy efficiency. Yet despite all these changes in the past 85 years, have there really been no adjustments in color metrics?

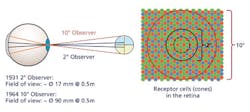

FIG. 1. White LEDs binned using existing industry practices can result in humans perceiving color discrepancy in general lighting applications. (Image by Osram.)

Well, yes, there have in fact been changes. In 1964 the CIE defined and published a new 10° Standard Observer color space. It has not been used in the lighting industry to this day. In 2015 the CIE made a fresh attempt and presented the CIE 2015 10° u´v´ color space - the second 10° color space after the 1964 one. So are the stars more favorably aligned for adoption by the lighting industry in this millennium than in the last? Osram Opto Semiconductors is convinced they are.

Same color location, different color perception

What makes this 10° binning for LEDs in general lighting so interesting? In the usual CIE 1931 2° color space, two LEDs can exhibit noticeably different white tones despite the exact same color coordinates (Fig. 1). In white chip-on-board (COB) LEDs, which are used as single light sources in wallwashers, spotlights, and downlights, these differences in color can be particularly unpleasant. The rising demands placed on the quality of light produced by LEDs has led in recent years to more and more discussions regarding color consistency. To tackle this problem, Osram has adopted white-LED binning for some COB LEDs based on the CIE 2015 10° u´v´ color space.

The greatest benefit of the 10° color space is that it provides for the correct and more realistic rendering of color perception. The cause of a lack of color consistency among white LEDs is the discrepancy between the color location determined in the CIE 1931 2° color space and the actual color perception by the human visual system.

In the CIE 1931 2° color space it is assumed that the blue, green, and red cones that are responsible for color perception in our eyes are evenly distributed. That does not match reality, however, as the density of the pigments varies greatly across the field of view. For example, there is a small area in the center where there are no blue cones at all. At a distance of 0.5m, the 2° color space only comprises a field of view with a diameter of 17 mm (Fig. 2). Most applications in general illumination are rated at a field of view of 10° (about a diameter of 90 mm at 0.5m distance) and larger. The different cone ratios at 2° and 10° therefore lead to distortions in color perception.

Spectral composition of light

But why are these distortions so pronounced with white LEDs? It has all to do with the spectral composition of the light - a problem that Bartenbach, the lighting design company, has recognized: The design firm did research that revealed some cases in which photometric evaluation of the light spectrum did not correspond to the actual visual appearance. Moreover, the difference was visible in some lighting design projects in which quality of light was highly valued. According to the effect known as metamerism, white light with different spectral compositions but with the same color location should actually be perceived as identical (LEDs Magazine published a four-part series of articles on color science covering metamerism and other concepts related to color perception).

FIG. 2. A 2° field of view, such as is used in LED binning today, can result in varying color perception because there are no blue cones in the center of the eye, and a 10° field of view is much more representative of how humans perceive light in general illumination applications.

To understand this subject properly, we need first to take a step back and remember that the light from white LEDs is produced by conversion from a blue chip. The wavelength of this blue chip may vary, but this is compensated by adjusting the phosphor or converter mix to achieve exactly the same color location for different LEDs. Even so, the spectral composition of LEDs differs in the blue range - and it is precisely here that the differences in color perception in the 2° field and the 10° field are particularly great. If an LED is optimized to exactly the same color location as part of extremely narrow 1-SDCM (standard deviation of color matching and often referred to as a MacAdam ellipse) binning for a 2° observer and if at the same time no differences are measured, then precisely these spectral differences can lead to perceivable color discrepancies in a typical general lighting application that corresponds more to a 10° observation field.

Matching human perception

Osram is convinced that white binning with a 10° viewing angle corresponds much more closely to human color perception in general-lighting applications. When it comes to 10° binning, major color differences can be avoided through different spectral shapes. The company combined the latest scientific findings on cones with fundamental knowledge about the chromaticity chart with its important axes in terms of physics and is applying the results to some LEDs used in general illumination.

FIG. 3. The Osram Opto Semiconductors Soleriq S 13 is the first LED to be binned based on the CIE 2015 10° u'v' color space.

The technology that Osram calls TEN° is available initially in a series of COB products, namely the third generation of the Soleriq S 13 (Fig. 3), which has been on the market since March 2016. The new binning methodology means that these LEDs will guarantee unprecedented color consistency. Meanwhile, the new Soleriq LEDs continue to be compliant with current industry standards, and continue to be compatible with existing white groupings. The 10° binning will by no means replace existing standards, but only add to them for now. This still enables customers to implement their specific products and applications without any problems.

FIG. 4. Hospitality applications are one of several project types in which uniform white perception is considered a critical element of lighting design.

Future of binning

Whether the Soleriq S 13 remains the only LED series binned to the 10° color space depends on market acceptance by the international lighting industry. Osram believes that the technology delivers a reliable, cost-effective, and intelligent approach to resolve the problem in LED general lighting between high quality requirements on the one hand and cost pressures on the other. The binning scheme will enable lighting designers and specifiers to deliver projects with uniform whites in residential and commercial applications where light quality is important, such as in hospitality (Fig. 4).

Already some noted lighting practitioners share our opinion. "Osram's new white binning is the right way to improve the quality of an LED-based lighting system," was the comment from Bartenbach. And a representative of NEL Neontechnik Elektroanlagen Leipzig GmbH said, "I can only agree with what the Bartenbach Institute has said - it's the right step in the right direction. As a scientist I could possibly add that it's been a long time coming, and it's necessary. I just hope that the market will now do it justice."

ALEXANDER WILMis an application engineer and key expert in SSL solutions at Osram Opto Semiconductors in Regensburg, Germany (osram-os.com).