High-performing, longer lasting mAgic® Sinter Paste to be showcased Heraeus Electronics at Strategies in Light Conference February 13-15

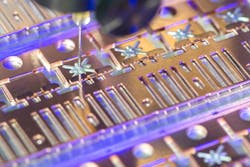

Innovative sinter pastes optimized for high-power LEDs, including vertical chips, flip chips and CSPs.

LONG BEACH, California- February 14, 2018- Heraeus Electronics, a leading provider of materials solutions for the semiconductor and electronic packaging industries, announced it will showcase its high-performance mAgic® Sinter Paste at the 2018 Strategies in Light/LED Show February 13-15 in Long Beach, California. Optimized for high power LEDs, mAgic® Sinter Paste is specifically designed to meet the needs of next-generation LED applications, including vertical chips, flip chips and chip scale packages (CSPs). The paste is also available in rheologies suited for dispensing and pin-transfer processes.

As high power LED continues to advance toward higher luminance, longer lifetime and smaller packages, sinter pastes must be able to provide robust performance to meet these demanding requirements. With junction temperature typically able to reach or exceed 150°C, the challenge is for interconnect material between die and substrate to effectively manage the higher power dissipation. Heraeus Electronics mAgic® Sinter Paste, developed as a lead-free, Halogen Zero formulation, is an effective die-attach solution for segments such as power discrete, HP LED and RF power devices. It enables higher operating temperature and increases efficacy through superior thermal conductivity (greater than 100W/mK), and electrical conductivity (less than 10MS/S). Another key attribute is its No Self-Aligning feature, which is especially beneficial for miniaturization applications requiring high precision.

Some of its essential benefits include:

- Low sintering temperature at 200 ºC

- Sintering enables a second and third reflow without weakening the die attach, ensuring high placement accuracy

- Improved thermal conductivity (greater than 100W/mK) compared to solder paste for applications requiring higher thermal dissipation; excellent electrical conductivity (greater than 10SM/m)

- Reliable and robust performance that can increase the lifetime of a device up to 10 times

- Reduced processing costs, as no flux cleaning after processing is required due to its compatibility with high-volume manufacturing processes

Dr. Michael Joerger, Global Head of Innovation for Heraeus Electronics, said, “At this conference and across the LED industry, manufacturers face a common challenge in their innovation efforts: unlocking greater performance capabilities of die attach materials.” Joerger believes Heraeus mAgic® Sinter Paste “can be a solution to eliminate those speed bumps and bottlenecks. It performs flawlessly and delivers superior results in the most demanding processes and applications.”

Heraeus Electronics will be exhibiting at the 2018 Strategies in Light Conference in Long Beach, California from February 13-15 at booth 336.