What comes to mind when someone mentions connected LED lighting system for the industrial & commercial (C&I) application? Is it energy saving, networking, remote control, or data collection? How about interoperability?

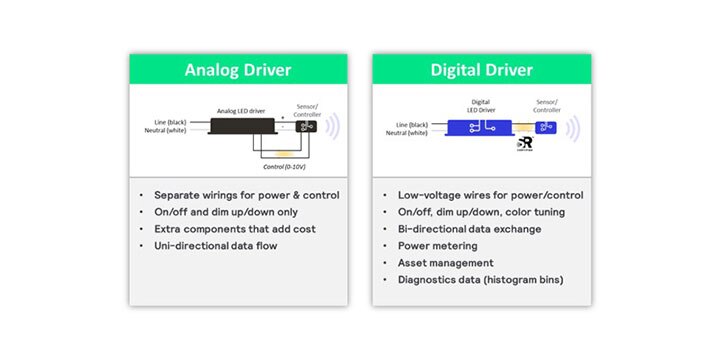

Your answer to that question may depend on the level of connectivity you design into the lighting system. The following diagrams illustrate the different level of connectivity.

Group A: This is the simplest setup. The luminaires might be standalone and not connected to anything other than the wall switch. They use the analog LED driver.

Group B: The luminaires and are part of a lighting control system. They too use the analog LED driver.

Group C: The luminaires not only utilize the latest digital lighting control system, but are also equipped with the digital LED driver.

The last category represents a growing segment of the luminaires that are being installed today. The reason they are becoming more popular is that they support all the characteristics listed above—energy saving, networking, remote control, data collection, and interoperability—from day one.

Shown on the left is a “traditional” LED luminaire that utilizes the analog LED driver. This configuration probably represents a vast majority of the LED luminaires that have been installed today. To control these luminaires, for example, with a DLC-qualified network lighting control (NLC) solution, additional control interface device are typically required to connect to the analog driver(s) inside the luminaire. You can turn the luminaire on and off and you can also dim down the light output—either locally or remotely—but that is about it. This is because the analog LED drivers can only “execute” commands that are sent by the lighting sensor or controller. The other downside is the extra cost introduced by the additional control interface device.

In contrast, the digital LED drivers, such as Philips Xitanium SR LED drivers, open a new paradigm that is well-suited for the internet of things (IoT) world. First, Philips Xitanium SR LED drivers not only eliminates the extra control interface device, but also supports a standard-compliant intra-luminaire digital interface, or Sensor Ready (SR) interface. Think of this as the information superhighway inside the luminaire that connects the digital LED driver to the outside world. This connectivity enables you to design connected lighting system with a growing list of SR-compatible NLC solutions from companies such as Lutron and Enlighted, just to name a few.