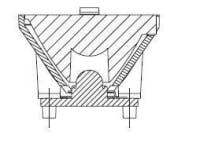

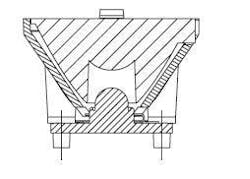

Date Announced: 10 Feb 2010 -- New material created in collaboration with Carclo Technical PlasticsSanta Clara, Calif., -– Manufacturers of LED (light emitting diode) optics understand that the larger the optic, the greater the material light loss. Bayer MaterialScience LLC has developed a grade of polycarbonate resin that allows for up to 92.3 percent efficiency in a 30mm diameter optic lens – an industry feat. The new Makrolon® LED2643 polycarbonate is also expected to soon meet the latest UL 8750 standards for LED lighting, (UL-94 V-2 rating).This material will be featured at Bayer MaterialScience’s booth (#201) at the Strategies in Light conference Feb. 10-12 in Santa Clara, Calif.Bayer MaterialScience collaborated with a team at Carclo Technical Plastics, an optics design and manufacturing firm located in Latrobe, Pa., to develop a grade of polycarbonate resin that would meet the requirements of a new Carclo 30mm diameter optic. The optic’s large size – larger than the typical lenses Carclo manufactures, which have diameters of 20mm or 26.5mm – is necessary in order to efficiently collimate all the light from large diameter LED light sources. With this in mind, Bayer MaterialScience LLC formulated a very low-loss material because all optics, and especially optics this large, naturally absorb some light due to their mass. “When we tested 30mm optics made from the new Bayer material with a Seoul Semiconductor P7 LED, we were just overwhelmed with the results,” said Jim O’Connor, business development manager, Carclo Technical Plastics. “A standard optical grade of polycarbonate achieves about 87 percent efficiency, so we are thrilled with the performance results – 92.3 percent efficiency – achieved with the new Makrolon® LED2643 polycarbonate.”“As an expert in developing materials for the LED market, we were pleased to be able to develop a resin that Carclo found met all of its requirements,” said Gerald DiBattista, market segment leader, IT, Electrical/Electronics Polycarbonates, Bayer MaterialScience LLC. Makrolon LED2643, a robust, molder-friendly material, is the latest addition to Bayer MaterialScience’s extensive portfolio of polycarbonate resins for the burgeoning LED market. The polycarbonate is Underwriters Laboratories Inc. (UL) listed, as well as achieving an f1 rating, making it suitable for many wet outdoor applications. This tough, impact resistant material exhibits excellent weatherability, elevated heat resistance and high light transmittance. Makrolon LED2643 also has a high molecular weight, which translates into improved productivity for molders.The material’s higher viscosity enables faster part solidification, which can help molders produce parts faster and with fewer defects. This is especially ideal for optics manufacturers such as Carclo when producing large lenses for lighting products that are used in various markets, like architectural lighting, where efficiency is a highly desirable attribute.“Our experience with Bayer MaterialScience LLC has been nothing but positive, as they always take the time to understand our needs and have delivered an excellent new optical polycarbonate material,” said O’Connor. “Working together, we have achieved ground-breaking results that truly combine Carclo’s world-class optical designs with the latest in high performance polycarbonate materials.”Bayer MaterialScience LLC is one of the leading producers of polymers and high-performance plastics in North America and is part of the global Bayer MaterialScience business with nearly 15,100 employees at 30 sites around the world and 2008 sales of 9.7 billion euros. Business activities are focused on the manufacture of high-tech polymer materials and the development of innovative solutions for products used in many areas of daily life. The main segments served are the automotive, electrical and electronics, construction, medical, and sports and leisure industries. This news release may contain forward-looking statements based on current assumptions and forecasts made by Bayer Group or subgroup management. Various known and unknown risks, uncertainties and other factors could lead to material differences between the actual future results, financial situation, development or performance of the company and the estimates given here. These factors include those discussed in Bayer’s public reports which are available on the Bayer website at www.bayer.com. The company assumes no liability whatsoever to update these forward-looking statements or to conform them to future events or developments.

Contact

Contact: Bill Allan, Phone: 412-777-5200 E-mail: [email protected] For more information about Bayer MaterialScience’s Makrolon polycarbonate resin, call 1-800-662-2927, e-mail [email protected] or [email protected] or visit www.bayermaterialsciencenafta.com. For more information about Carclo Technical Plastics, Inc., call 724-539-1833 or visit www.carclo-plc.com.

E-mail:[email protected]

Web Site:www.bayermaterialsciencenafta.com