This article was published in the September 2011 issue of LEDs Magazine.

View the Table of Contents and download the PDF file of the complete September 2011 issue.

+++++

Much attention in the LED lighting world has focused on two applications that are at polar extremes; low-power incandescent bulb replacement and high-power street lights. While these applications are ubiquitous and iconic, there is also a range of area-lighting applications – such as parking garages, park lighting, stairway lighting – and outdoor commercial lighting – such as wall packs, wall washers, and security, flood, gas-station canopy and pathway lighting – which are hiding in plain sight. These medium- to high-power applications are ideal candidates for solid-state lighting (SSL), and new LEDs that operate at higher drive currents and produce more lumens are a good match. Designing a luminaire with fewer brighter LEDs can also simplify the driver electronics and ease the task of adding adaptive controls.

The applications mentioned above are a good match with LEDs, because they consume large amounts of power, have high hours of annual use, and are used in public spaces that may not be occupied for many hours, thus opening the door for adaptive controls and dimming that can significantly reduce energy consumption. Beyond energy cost, a driving factor of LED lighting is long life and reducing the maintenance cost of bulb replacement.

Traditionally, the aforementioned medium-power applications have used high-pressure-sodium (HPS) and metal-halide (MH) light sources. HPS light sources are actually very efficient but generate a decidedly yellow/orange light that has very poor color rendering since the light source is nearly monochromatic.

MH sources display better optical characteristics but have slightly lower initial lumen output, shorter lifetime, and higher lumen degradation over the useful life. MH lifetime (measured to 50% failure point of the population) is in the 10-20,000 hour range depending on the bulb design and construction, whereas HPS has typical lifetimes of 24,000 hours.

HPS and MH sources are also limited in terms of adaptive controls and dimming. And most of these area-lighting applications require directional light. Although HPS and MH bulbs have high lumen output, 40-60% of the generated light can be lost in the fixture.

LED life and controls

High-brightness white-LED light sources address many of the limitations of the legacy lighting technologies as they are inherently directional in nature, have very long operating lifetimes, provide white light with good color rendering and, given their instant-on characteristics, are easy to dim across a wide range of light levels.When white HB-LEDs came on the market, the most common configuration was called a “1W” LED because when it was driven with 350 mA, it typically dissipated around 1.2W given a nominal forward voltage of 3.3-3.5V. Today, widely-available 1W LEDs can generate more than 100 lumens at an efficacy of over 100 lm/W. To generate 5000 delivered lumens a fixture needs on the order of 50 LEDs whereas 18-24 months ago the same application may have required 80-100 LEDs.

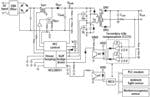

To power such a large number of LEDs from the AC line, drivers have typically used a three-stage power-conversion architecture as illustrated in Fig 1. A two-stage constant-voltage power supply implements power-factor correction (PFC) in the first stage, followed by a high-voltage DC-DC converter that generates a safe isolated voltage rail typically in the range of 28-60 VDC.

The fixed-voltage output rail supplies multiple strings of LEDs. A third-stage, a dedicated buck DC-DC LED driver, provides regulated current to each string. Depending on the output of the second stage and the forward voltage of the LEDs, each string might include 8-12 LEDs.

Brighter LEDs

Some LED manufacturers have developed advanced processes and improved LED chip designs that deliver more lumens at higher drive currents while maintaining the same forward voltage. For example, the Cree XM-L is rated for up to 3A drive current and has a very low typical forward voltage of 3.1V at 1500 mA drive current. At 1500 mA and 85°C junction temperature, in cool white, each LED generates 440-475 lm. A fixture that uses just 12 such LEDs would have an output in the range of 5200-5700 lm with a typical load power of around 53W, delivering over 100 lm/W efficacy.

Going from 50 LEDs in the previous example to 12 simplifies the optics but it has a more sweeping impact on the driver architecture. Now all the LEDs can be safely driven in a single string, eliminating the need for multiple parallel DC-DC LED buck drivers. This also improves light uniformity as all LEDs are driven at the same exact current.

To eliminate the third stage, the two-stage constant-voltage LED power supply is replaced with a constant-current LED driver. This provides two fundamental advantages. The overall system efficiency is improved as one power-conversion stage is completely eliminated, and the cost and design complexity of multiple DC-DC converters is eliminated. It also simplifies adding intelligent control as the dimming function can now be integrated in the current-control loop of the constant-current LED driver.

Adaptive controls have been used in indoor lighting for a number of years and involve combining sensors with networked or autonomous microprocessor-based controls to optimize the lighting level to the needs of the environment. Simple examples include adding an occupancy-sensor lighting control to turn off a light source when there is no activity for a prescribed time.

Control scenarios

In area lighting, controls have been mostly limited to on and off at dusk and dawn. But dimming LED light sources is very straightforward compared to HPS and MH light sources that have long turn-on and restart times. LED light sources can be dimmed across a wide range and can rapidly turn on to 100% brightness based on activity or occupancy. In an outdoor park-lighting scene, for example, this means the light along the running path or walkway can be turned down significantly when no activity is detected and instantaneously turned to full brightness if a jogger runs down the trail in the middle of the night.

Fig. 2 illustrates a possible dimming profile through the course of a typical evening. The gray area represents timer-based control and the blue areas indicate those times that the light source is increased to 100% when activity is detected. The energy savings can be substantial since most of the operating hours are at the reduced energy-consumption levels.

Let’s consider an example of how new high-lumen packaged LEDs can simply the luminaire system architecture and efficiently convert AC power into a regulated current in the 1-3A range (Fig. 3). Such an LED driver design can also incorporate support functions to enable adaptive controls. The addition of a low-cost microcontroller (MCU) opens the door to more-sophisticated control schemes that can monitor ambient light, occupancy/activity sensors, time of day, and day of week to provide appropriate light in a variety of situations while maximizing energy savings.

MCUs and networks add functionality

For centralized control, these smart luminaires can be networked, for example using a power-line-communications (PLC) modem block (Fig. 3). Alternatively, a system can use a wireless interface like Zigbee, a traditional wired interface such as Ethernet, or existing lighting and building controls.

The MCU monitors sensor feedback and network communications to control the light level. Moreover the MCU generates a PWM signal that is used to turn on and off the half-bridge driver, thereby controlling the light level. The PFC block implements a critical conduction mode (CCM) control scheme which achieves high power factor (>0.98 typical) with low harmonic content and is suitable for applications up to 200W.

Efficiency and power factor

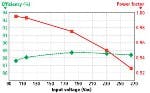

This driver architecture can support a wide range of power levels. Fig. 4 illustrates the typical efficiency and power-factor curve of an example driver design based on the NCL30051 driving 2A with a nominal LED load of 55W. Across the 115-240 VAC line-voltage range, the efficiency exceeds 88% and the power factor is greater than 0.94.

New LEDs that have high source-lumen capability can greatly simplify the LED driver architecture by reducing power-conversion stages and increasing overall power-conversion efficiency. Adding smart controls can yield further energy savings and opens the door to new capabilities such as constant-lumen-output operation modes. Here, the driver can control the LED current to maintain constant lumen output over lifetime to combat lumen depreciation. Smart dimming-control techniques have an additional benefit of extending the operating lifetime of the LEDs as well as the driver electronics by reducing the average operating temperature.