Horticultural LED products require careful design to deliver on performance needs. MARKUS BUSZ describes a closed-loop control architecture using spectral sensors to monitor and balance LED shifts, automatically adjust light output, and deliver optimal light recipes for indoor farms.

LEDs are already widely used in households and commercial buildings and now the development of new types of LEDs is spurring penetration into other market segments, including greenhouses and vertical farms. These agricultural or horticultural settings have traditionally used high-pressure sodium (HPS) lamps as an artificial light source, but over time, LED manufacturers have developed new generations with better and richer spectral characteristics that are more efficient and more cost effective than earlier LEDs (see the feature from this issue for details on application-specific packaged LEDs).

These new LEDs offer low power consumption, radiate little heat and operate over a long lifetime, making them superior to traditional HPS lamps. Moreover, these improved characteristics open new possibilities in the horticultural market. For example, farmers can now bring the luminaires closer to the plants, and also control their intensity and their spectral emissivity to optimize the plants’ growth. This has two benefits: it allows growers to increase the plant density in greenhouses through tight vertical stacking of plants (also called vertical farming), and growers can optimize the growth cycle and therefore the greenhouse occupation time. It’s benefits like these that are helping LEDs become the preferred source of illumination in horticultural lightingequipment.

Nevertheless, LEDs exhibit some limitations which need to be carefully handled to achieve stable illumination and optimal plant growth. The use of a spectral sensor-driven closed-loop control architecture can address theselimitations.

The value of grow lamps

Many plants grow only in specific geographic regions and at specific times of the year. This is linked in part to the plant’s temperature and humidity requirements. Another important factor, however, is the source of light to which they are exposed, which has a direct effect on photosynthesis and therefore on the plant’s capacity to generate the energy needed for growth.

Some researchers have found, for example, that the intensity of irradiation with light at a wavelength of 680 nm is critical to the growth rate of tomato plants during the germination phase but has little effect after germination. During the vegetative phase, irradiation with 650-nm light optimizes growth and the concentration of chlorophyll-a pigment. Their research concludes that each phase of the growth period — germination, vegetative, and fruition phase — requires irradiation with differentwavelengths.

The cultivation of tomatoes year-round in the northern hemisphere calls for greenhouses, which shelter the plants from harsh winter weather, equipped with lighting systems which compensate for the lack of natural light during the winter and which produce the optimum spectral characteristics for growth. If the lighting system can also mirror the daily variation of the sun’s spectrum, to align with the plants’ circadian cycle, the optimization of the artificial lighting solution will be complete.

Like tomatoes, other plants require their own specific spectral light profile to grow and to trigger photosynthesis. This profile encompasses both the spectral wavelength range and the circadian rhythm. The spectrum of light used for horticulture is mostly in the visible light spectrum: wavelengths from 400–700 nm. The peaks are in the red and the blue range. Nevertheless, each plant needs the full spectrum for optimal growth. The circadian rhythm depends on lighting conditions in the region from which each plantoriginates.

Because of variations even between plants of the same type, the quality of light can have a large impact on the productivity, growth, and development of specific plants. Monitoring the intensity, spectrum, and circadian rhythm of the light source helps ensure the provision of the optimal grow lightconditions.

Temperature dependence of LED spectral emissivity

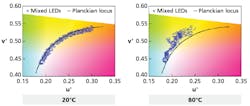

Fig. 1 shows how the spectral emissivity of a light source using a mix of red, green, and blue (RGB) LEDs changes over temperature. The horizontal axis shows the wavelength and the vertical axis thebrightness.

FIG. 1. Dependence of wavelength and brightness relative to the temperature of an RGB LED.

The curves clearly show the emissivity of a red LED is affected by temperature changes much more than that of a blue LED. The brightness decreases by almost 40% over the temperature range from 5°C (41°F) to 70°C (158°F).

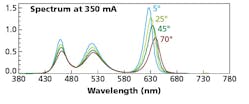

This changes the color of the light output from luminaires — a worrying effect for manufacturers of horticultural lighting systems, which are required to emit light at precisely specified wavelengths. An example is shown in Fig. 2: While the luminaire’s characteristic may be very close to the ideal black body curve or Planckian locus at ambient temperature, its emissivity diverges considerably from the target when the ambient temperature increases to 80°C.1

FIG. 2. Measured color drifts of mixed LEDs.

As previously mentioned, optimizing the growth of plants is less about the color of light as perceived by the human eye that is important, but rather the actual spectral profile of the output. Therefore, controlling the spectral emissivity of a luminaire over temperature calls for knowledge of the spectral profile of the emitted light.

LED ageing effects

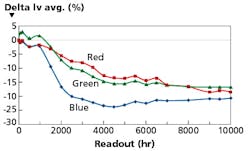

The lifetime of an LED is usually defined as the time it takes for its brightness to drop to 70% of its brightness when new.

Fig. 3 illustrates the change in the brightness characteristics of a high-power RGB LED in its first 10,000 hrs of operation. These characteristics vary from one manufacturer to another. Brightness loss within the first 5000 hrs typically varies between 5% and 15%. Interestingly, Fig. 3 also shows that the variation of brightness is not the same for all LEDs and the brightness attenuation is greater for the blue LEDs than for the green and the red LEDs.1

FIG. 3. The ageing of LEDs over lifetime.

The drop in brightness over time will require the periodic replacement of LEDs in a lighting system — a difficult and expensive maintenance task that increases the cost ofownership.

Optical feedback systems

The proper operation of horticultural lighting systems thus requires adjustment of the output over time and temperature to maintain the specified chromaticity andintensity.

One technique for achieving this is to stabilize the current and voltage of the LEDs. Another is to measure the temperature of the LEDs and report these values to the LED driver to implement a temperature control loop. These solutions perform indirect regulation and rely on predictive ageing models of the phosphorus material in the LED. They also require tight binning of the LEDs used in the production of theluminaires.

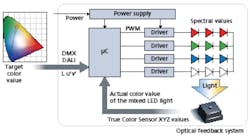

A better technique is the closed-loop regulation method described next. As Fig. 4 shows, this solution differs from the unregulated control solutions in that it uses a spectral sensor, which measures the actual spectral profile of the light in real time and directly controls the LED driver or controller to adjust the output until it matches the specified target values for chromaticity andintensity.

Fig. 4 demonstrates a mixed LED system. The principle works for any LED light source, such as RGB + white, RGB white + amber, or spectral grow light systems with four or more spectral LED channels.1

FIG. 4. Closed-loop optical feedback system.

The collection of light for the sensor can be achieved in various ways. One is to design a light guide into the luminaire that collects light from multiple LEDs and directs the mixed light to the sensor. Another is to design a spectral sensing unit that may be placed outside the luminaire, directly at the level of the plants, and to build a communications interface to the driver. In this case, the sensing unit may also detect and react to daylight.

AS7265x sensor chipset

The closed-loop control architecture requires a small sensor device that is capable of measuring in high resolution the spectral profile of the light emitted from a luminaire’s multiple LEDs.

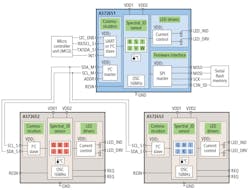

A product introduced by ams provides the required capabilities: The AS7265x is a chipset consisting of three highly-integrated, six-channel spectral sensor devices, each only 4.5×4.4×2.5 mm, in LGA packages with integrated apertures, which control the light entering the sensor array. The device family integrates Gaussian filters into standard CMOS silicon via nano-optic deposited interference filtertechnology.

Thanks to a master-slave-slave architecture, the three sensor ICs are seen by the host as a single logical device, simplifying system integration and decreasing development time. Intelligence integrated in the AS7265x converts the raw light measurements into a calibrated digital output and manages the interface to the host microprocessor via I2C or UARTinterfaces.

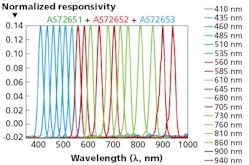

The AS7265x’s 18 channels span wavelengths in the visible and near infrared (NIR) spectrum at 20-nm spacing, with wavelength center-points at 410, 435, 460, 485, 510, 535, 560, 585, 610, 645, 680, 705, 730, 760, 810, 860, 900, and 940 nm. This AS7265x filter characteristic covers exactly the wavelength range needed for optimal grow-light illumination, a spectral profile known as the McCree curve.

The AS7265x’s interference filters offer extremely precise and reproducible characteristics that are stable over both time and temperature. They enable ams to produce spectral sensor ICs that are much smaller and more cost effective than the typical component solutions needed for high-channel-count spectral analysisinstruments.

FIG. 5. Block diagram of AS7265x.

The AS72651/652/653 chipset is calibrated at the factory, delivering a normalized 35 counts/µW/cm2 across the entire sensed spectrum and simplifying algorithm development. Combined with the high filter stability over time and temperature, this allows a “calibrated-for-life” design, which lowers both components and manufacturing costs, and enables new application spaces such as horticultural lighting (Fig. 5).

The small size of the AS7265x chipset, combined with its low power consumption, enables lighting manufacturers to develop new horticultural lighting systems that take advantage of these uniqueattributes.

The system is able to monitor the spectral emission profile and brightness of plant illumination systems in the luminaire or directly at the plants. Thanks to their spectral filter characteristic, the AS7265x sensors can monitor parameters such as PAR (photosynthetically active radiation) between ~400 and ~700 nm, which is the range of light frequencies at which plants perform photosynthesis (Fig. 6). Furthermore, the spectral data of the sensors can be used for monitoring wall-plug efficiency, the ratio of electrical power input and optical power output of LEDs.

FIG. 6. AS7265x filter characteristics.

Initial in-house tests by ams confirm that the accuracy of the AS7265x can be close to that of laboratory-grade spectrometers with suitable calibration of the lighting system.

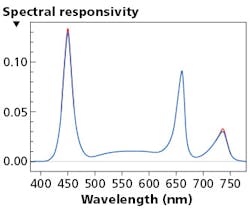

Fig. 7 shows the difference between the measured values provided by a spectrometer (red) and the AS7265x sensor (blue). In this case, ams measured absolute values to enable a benchmark of the AS7265x sensors versus a spectrometer. If the closed-loop control scheme measures only drifts from a standard profile, factory calibration is good enough for measurement of relative values.

In addition to monitoring ageing effects and temperature drifts in spectral LEDs, the AS7265x sensors enable the detection of daylight influences. This information may be used to dim the intensity of those wavelengths emitted by spectral LEDs that are already present in daylight. This provides for additional energy and cost savings, while maintaining optimal illumination of plants.

FIG. 7. Spectral comparison of spectrometer values versus sensor values after calibration (red – spectrometer, blue – sensor).

Overall, the closed-loop control method enabled by the spectral 18-channel AS7265x sensor chipset enables horticultural lighting manufacturers to develop fully automated lighting systems with features such as:

- Automatic compensation for the influence of daylight

- Automatic adjustment to circadian rhythms

- Automatic balancing of LED drifts over lifetime andtemperature

Conclusion

In the future, LEDs will be the light source for most horticultural lighting systems, replacing traditional HPS luminaires. The reason for this migration is the lower cost of ownership of LED light sources, which offer better power efficiency, lower radiated heat, and longer lifetime. These new LED-based lighting systems will be smarter, connected, and sensor-rich, and will bring better control and automation capabilities to greenhouses. Spectral sensors will monitor both the lights and the photosynthetic activities of the plants. These values will be used to optimize the grow lightautomatically.

Using spectral sensors such as the AS7265x devices, horticultural lighting systems can be more efficient and more stable over the long term. The sensors open new capabilities such as automatic light profile balancing and growth monitoring. This reduces the effort required to grow crops, saves energy, and helps optimize crop yield and quality.

Reference

1. wp12362e light color regulation V1_0 – Dr. Fred Grunert, Dr. Wilfried Mahler, MAZeT GmbH.

MARKUS BUSZ is marketing manager for ams’ Color & Spectral Sensors (CSS) business line with a focus on spectral sensing applications. He began his sales career in 1993 when he joined Richter-Leuchten as a sales engineer for lighting systems. In 2005, he worked for Komos, an OEM supplier for the automotive and electric industry, as a sales engineer and project leader in preparation for the mass production of automotive parts. In 2008, Busz began working with MAZeT in the sales group. With ams’ 2016 MAZeT acquisition, he began his current position as a marketing manager at CSS. Busz holds a State-Certified Technician Degree in electronic engineering from Technical College in Hermsdorf. Busz is a German citizen.

Horticultural technology plants seeds of opportunity

The fall season is upon us, bringing with it LEDs Magazine’s third annual Horticultural Lighting Conference, this time landing in Portland, OR on Oct. 9 at the Hilton Portland Downtown.

As evidenced in this issue, strategies for designing solid-state lighting (SSL) systems that can handle the diverse needs of various plant cultivars in relatively harsh indoor conditions continue to advance. As explained here by Markus Busz, the programmability of spectral sensors enables the development of smarter indoor farming systems, which can learn and adapt to the conditions needed to maximize operations for vertical farms and other controlled environment agriculture (CEA) installations.

At the conference, keynoter Dr. Erik Runkle, who leads Michigan State University’s vertical farming research facility known as CELL (Controlled-Environment Lighting Laboratory), will provide an overview of how LED lighting can be used in photoperiodic, supplemental, and sole-source roles for specialty crops. In another design article from this issue, get a closer look at how to design robust SSL systems that operate under these tricky conditions, where water, soil, humidity, power delivery, and more can influence the performance of a poorly-executed product. Littelfuse’s Todd Phillips covers several factors that influence the electronic circuit design and provides engineering tips on how to meet safety standards and achieve consistent performance with optimized SSL designs.

During the full-day conference, industry leaders will also tie the technology potential to business and market growth opportunities that can help next-generation agriculture and the SSL industry to thrive. We’re sure that both LED component and SSL product manufacturers are keen to find out what the latest horticultural lighting forecast holds. Strategies Unlimited research director Philip Smallwood (shown) has said before that revenue from horticultural SSL products will approach $3B by 2022. We’re looking forward to Smallwood’s presentation on this still-emerging market; you can also find in-depth analysis in the 2018 horticultural lighting market research report available from Strategies Unlimited.

We’ll provide more coverage on the conference in an upcoming issue of LEDs Magazine. — Carrie Meadows