This article was published in the November/December 2011 issue of LEDs Magazine.

View the Table of Contents and download the PDF file of the complete November/December 2011 issue.

+++++

The Strategies in Light (SIL) Europe conference and exposition was held in Milan, Italy on October 4-6 and featured two days of discussion regarding the technological developments that go into solid-state lighting (SSL) products. A key message of these presentations rings true: LED lighting has matured to the point where luminaire design, whether it is for street lights, recessed downlights or integral replacement lamps, must bring together optimized drivers, optics and thermal design to best take advantage of all that LED technology has to offer. SIL Europe also featured parallel sessions in the Market Transformation track (page 21).

Luminaire design

Hans Laschefski, a consultant with Alanod Aluminium-Veredlung GmbH in Ennepetal, Germany, discussed a trend toward multiple reflectors as a means to control glare with high-power arrays of packaged LEDs. As the industry moves to smaller, denser arrays, glare increases and must be managed to provide an acceptable user experience. “When evaluating glare, people often talk about the average luminance, but since LEDs are spot-light sources, we should evaluate the spot illuminance, which is unfortunately difficult since the necessary measurement equipment is not typically available,” he explained.

Laschefski showed several advanced reflector designs, all of which do not use lenses directly on the packaged LEDs but rather have the LEDs facing angled mirrors and reflectors. This helps to improve the light distribution, achieve better color mixing, and reduce glare. One of the advantages to having very-high reflectivity from aluminum-based alloys (95-98% reflectance with Alanod's Miro and Miro Silver reflectors) is that multiple reflections can eliminate the observation of a point-light-source by a person looking directly at the luminaire. For instance, in the Deflecto luminaire street light by AriannaLED of Padova, Italy (Fig. 1), the multiple reflections sufficiently scatter the light. “In these designs, you cannot even tell the light source is an LED,” Laschefski said.

The importance of visual comfort with LED luminaires was also emphasized by Giorgia Tordini, an optical designer with Philips Professional Lighting Solutions, who presented “The visual barrier: Designing the night appearance of an LED product.” She defined night appearance as a person's visual perception when a light is first switched on in its application. Very high luminance from LED light (10⁸ cd/m²) can cause glare, which is an uncomfortable reaction to brightness. Tordini noted that glare is different from photo-biological damage, which is caused mainly by light in the UV realm.

Tordini described the optical system of Philips’ DayZone luminaire for office lighting, which has a task light in the middle and a separately-controlled outer ring-light for ambient lighting. The luminance of the outer ring is 3x smaller than that of the inner portion. The luminance limit for work spaces, according to British Standard EN-12464, is 1000 cd/m2 at a 90-degree to 65-degree angle from the vertical axis.

Tordini explained that the optical design uses primary optics at the LED level (which is a multi-LED package) to convert the light distribution into a controlled beam. The plastic optics consists of a microlens array fabricated from polymethylmethacrylate (PMMA). This serves to minimize chromatic aberration due to first-order interference, while enhancing scattering to allow a uniform visual appearance of light. Transmittance through the PMMA film is 92%.This patterned film is available in roll-to-roll sheets and therefore is flexible to apply in different shapes and sizes. Beyond this primary optic, a secondary optic, consisting of a hollow prism ring, modifies the light distribution and controls the light level transmitted to the target surface.

Achieving omni-directionality

Markus Hofmann, a senior development engineer with Osram GmbH of Munich, Germany, presented the pros and cons of four different approaches to achieving omni-directionality with integral lamps for residential applications. He said that omni-directionality can be achieved using light guides, reflectors, a remote phosphor or a three-dimensional (3D) arrangement of LEDs.

The key advantage of using light guides is that an incandescent-like bulb in appearance can be achieved. However, there is great light loss and low efficiency associated with this approach, and meeting Energy Star specifications (Fig. 2) is very difficult. As a result, light-guide approaches are currently limited to low-lumen-output, design-driven applications.

When it comes to achieving high lumen output, the remote phosphor approach is suitable because light losses are low and the phosphor is compatible with external aluminum fins that function as the heat sink. The downside, particularly in today’s market according to Hofmann, is the high cost of remote phosphors that contain rare-earth materials. Assembly of the bulbs is also a more complex process, he said, but Energy Star requirements can be met.

Alternatively, a 3D arrangement of the LEDs can meet high-lumen-output needs and also meet Energy Star requirements. Hofmann stated that 60W-equivalent (850 lm) and 75W-equivalent (1060 lm) lamps that meet Energy Star requirements with good CRI, CCT and lifetime have been fabricated using 3D approaches. “Realization of 100W-equivalent lamps with 3D LED arrangements will be coming soon,” he added.

Another presentation in the same session revealed a less-traditional approach to fabricating and marketing retrofit lamps. Martijn Dekker, CTO of Lemnis Lighting, an LED lamp maker based in the Netherlands, announced that Lemnis has entered into a multiyear commitment with a large retailer to develop and market cost-effective LED lamps. The first products are 400-lm and 200-lm lamps, which will be introduced in European stores soon. Although not confirmed by Dekker, the retailer is thought to be Sweden-based Ikea. While Dekker noted that the lamps do not meet Energy Star requirements and have a shorter lifetime rating (20,000 hours) than most replacement lamps, the overriding goal in development was achieving acceptable consumer price points while delivering quality lamps.

“The price target for these lamps was less than €9.99 ($13.77) for the 45W-replacement lamp and €6.99 ($9.64) for the 25W-replacement,” explained Dekker. The 400 lm lamp offers a CCT of 2700K and a CRI above 85. The LED design combines two red LEDs with four phosphor-converted blue LEDs, but the company plans to move to a phosphor-only array in 2012 products.

Dekker referred to the novel business agreement with Lemnis’ partners as a virtual vertically-integrated company involving the retailer, the lighting manufacturer, an LED fabrication partner in India and other supply partners. These companies are sharing the project risk to achieve long-term volume sales of LED lamps priced at $8/klm at the lamp level. “A non-integrated supply chain leads to a stacking of profit margins through the supply chain,” he said, which limits the industry’s ability to hit low commercial price points.

Optimizing optics

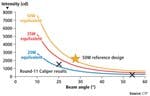

Among all retrofit lamps, perhaps the LED-based MR16, because of its small size, is one of the more difficult to design. Mike Bean, head of design and development at Carclo Technical Plastics (CTP), a designer and manufacturer of optical components based in London, UK, described the MR16 halogen lamp as a tough act to follow. “MR16 design using LEDs is quite a challenge…despite the fact that there are several commercially-available replacement lamps, most do not come close to the 50W halogen in performance,” said Bean. According to the US Department of Energy’s (DOE’s) Caliper testing of LED-based MR16 lamps, while 50W-equivalent performance is the goal, typical measurements are closer to those of 25W- or 35W-equivalent lamps (Fig. 3).

To achieve the required center-beam intensity and a narrow overall beam angle, one key to the lamp design is to combine smaller LEDs with focusing optics. Smaller LEDs and total internal reflection (TIR) optics allow the beam angle to be reduced from 40 to 27°, while still delivering 2250 cd at 27°. In this design, the 30-mm-diameter optic was optimally placed 15 mm above the multi-chip LED source, allowing the reflector to fit within the specified geometry of the MR16 lamp (per ANSI C78.24 specification).

SIL presentations also addressed luminaire design elements related to product life. Klaus Reinartz, director of the global LED program at Bayer MaterialScience LLC (BMS) in Leverkusen, Germany, explained how advanced polycarbonate materials can offer increased transparency in a thinner optical lens with a much smaller yellowness index than previous-generation materials. The company’s Makrolon products are stable against 90-degree LED light with an intensity of 46 lm/cm2, and the company is currently performing trials at higher temperatures and light intensities.

Advanced polycarbonate materials can be injection-molded into a wide variety of shapes and sizes to meet LED light transmission, shaping and diffusing needs. One of the newer developments that Reinartz described is thermally conductive grades of polycarbonate (up to 40W/m∙K), which can be custom-molded to act as a lighter, more flexible heat sink than aluminum options.

Driver and dimmer design

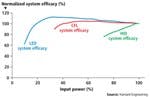

Rasib Khan, an engineering manager with Harvard Engineering plc, based in Wakefield, UK, presented a comparison of dimming system efficacy among LED, CFL and high-pressure sodium (HPS) light sources. The greatest energy savings are associated with using LEDs and appropriate dimming levels. As a comparison, HPS sources can only be dimmed to approximately 40% of their maximum lumen output and system efficacy is compromised with all levels of dimming (Fig. 4). In other words, higher input power is required to produce the same lumen output. For example, a 60W Cosmo luminaire with Harvard DALI ballast at a 50% light-output level requires approximately 67% of input power.

System efficacy is better with CFLs, where high efficacy is maintained down to about 40% lumen output levels. For a typical fixture, 30% lumen output requires approximately 35% input power. However, below a 40% dimming level, CFLs suffers from cathode and driver inefficiencies.

According to Khan, simple analog switch dimming (0-10V) works well on a small scale, but requires too much cable for large-scale implementations. More expensive control options such as DALI can provide greatwer flexibility for projects of all sizes and are re-configurable. However, DALI and other approaches require further work to fully maximize control efficiency and power factor over the control range. Ultimately, Khan expects the industry to move to wireless intelligent control systems capable of plug-and-play operation.

Also in the drivers session, Steve Roberts, technical manager at Recom, Austria, discussed the significant impact that high temperature can have on luminaire reliability. He made several design recommendations for minimizing temperature increases in LED luminaires including mounting the LEDs so that they have low thermal impedance to the heat sink and mounting the driver away from the LEDs and heat sink. The heat sink should be designed for the most efficient size/efficiency ratio. Thermal derating can be used to reduce the LED current if the junction temperature approaches specification limits. Roberts further recommends limiting thermal cycling and allowing for a single LED failure in multiple LED installations. Input-output voltage transients can be managed by using spike protection as well as short input cables with relatively-longer output cables.

Regarding triac dimmers, Roberts recommends that engineers consider the timing of triggers and the effect on the driver electronics. Rather than separate AC/DC ballasts, a centralized DC-power-distribution approach should be used with a large AC/DC power supply feeding multiple DC/DC LED drivers. Finally, Roberts recommends consideration of the reliability of every component in the luminaire system.

Designing power-distribution networks

A presentation by Marc Ottolini of iSotera Ltd of Hoddesdon, UK, considered the utility of DC-power-distribution networks for SSL. Ottolini compared four scenarios – the legacy architecture, a centralized DC Star approach where one AC/DC supply feeds DC/DC drivers, a DC grid where low-voltage DC leaves the AC/DC supply, or a centralized high-frequency AC (HFAC) bus approach. For each approach, he looked at simplicity of installation, cost, safety, reliability and controllability.

He concluded that there is no compelling benefit to implementing a full-DC-power-distribution system for LED lighting. However, a centralized (bulk) power processing approach can be advantageous if up and down (2-stage) conversion can be made efficient enough, which depends on the diversity of the LED load. He finalized with the statement that energy-efficiency benefits alone (2-5%) do not provide enough impetus to begin setting new standards.