Power supplies

A linear-style regulator could be used to provide a constant-current source for the LED. However, due to the nature of linear regulators, there is still a sizeable inefficiency as they use a series pass device (i.e. transistor/power FET) to perform regulation. This means that excess power is dissipated as heat in the device.

Using microcontrollers

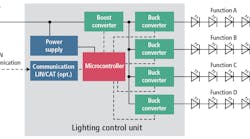

Inexpensive and versatile microcontrollers are increasingly being used to add an element of sophistication to power LED applications. Contemporary microcontrollers include integrated internal clocking, reset controllers, analogue-to-digital converters and pulse-width modulation (PWM) modules, among other elements.

Microcontrollers are available in small packages (for example 8-pin surface mount devices), including on-chip flash memory from less than US$1 (depending on volume).

PWM dimming

Very fine control of power LED brightness can be performed using PWM and again, various solutions are available from suppliers to achieve very effective control solutions. Due to the ability to achieve a very wide dynamic range in terms of dimming (>1,000:1), it is now possible to provide effective RGB colour-mixing solutions.

A number of companies have developed driver solutions that can be used as the basis for effective colour mixing/dimming products. A number of these solutions are available in modular form allowing for easy integration by the user with very little design time.

(An excellent application note describes the use of a Microchip PIC in a typical PWM dimming and control application.)

Automotive applications

One of the biggest success stories for both conventional high-brightness LEDs (such as Lumileds SnapLED and SuperFlux) and high-power LEDs (such as Lumileds Luxeon) is automotive.

High-power LEDs, however, feature the light output required to replace traditional bulbs on a one-for-one (rather than one-for-cluster) basis in exterior lighting applications including brake, fog and headlamps. Requiring less space, less energy, and improved system life and reliability, high-power LEDs can now be designed into these applications and system cost parity can be achieved.

2004 saw the first front lighting application in a production car with the unveiling of Audi's 12-cylinder, 6-litre A8 model. This uses a cloverleaf-shaped arrangement of five Luxeon LEDs for the daytime running lamp (DRL) as part of the main headlamp module (figure 3). This function is becoming increasingly important as more countries mandate the use of DRLs to reduce the number of collisions (see Audi specifies white LEDs for daytime running light).

Because of the flexibility and benefits of high-power LED technology, however, the design options don't end there. A new era of "intelligent" lighting is starting which will see "adaptive" beam patterns automatically triggered by varying conditions such as highway, in-town or curve driving. This will be possible because a light beam created by multiple LEDs can be programmed to angle, dim or brighten individual emitters to "adapt" the beam.

The use of Luxeon LEDs in the daytime running lamp of the Audi A8 6.0L indicates an approaching transition of solid-state technology for all headlamp components, including low and high beams, fog lamps and newer adaptive front lighting systems that contribute additional light while turning. The first high-power LED-based adaptive lighting systems are expected by 2007 and have already begun to appear on concept cars from Ford, Audi and Renault (see Conceptual LED headlamps see around corners).

Furthermore, Toyota has also already started shipping its Estima model in Japan which uses a single Luxeon LED to replace the conventional brake lamp bulb. (It is worth noting that no other commercially available single, solid-state light source has yet proven powerful or reliable enough to meet stop lamp specifications with just one LED).

Mobile camera phone flashes

The Luxeon Flash LXCL-PWF1 (see figure 4) provides an output of 40 lm at 1 A, and an LXCL-PWF2 LED delivers 80 lm at 1 A. By contrast, conventional LEDs produce just 6 to 7 lm. The Luxeon Flash products are also rated for 100,000 flashes at 1 A and 168 hours of DC (flashlight/torch mode) at 350 mA. (see White LEDs from Lumileds improve functionality of phone flashes).

High-power LEDs are the future

It is not an exaggeration to say that power LEDs are set to revolutionise an entire new generation of automotive, industrial, medical, domestic and leisure lighting applications. Indeed the list seems to grow daily. In medical, for example, high-power LED technology is already being used in hand-held dental curing devices, as well as state-of-the-art skin cancer therapy systems, due to the highly controllable LED emissions wavelengths.

Although high-power LED technology works and is here today, its biggest challenge is that it is still regarded as "next generation" in many quarters. Many applications that would benefit massively - if only in the product differentiation stakes alone - have yet to recognise the underlying potential of power LEDs.

This, however, is nothing new for transformational technologies such as power LEDs. Whether they become an overnight success or not in certain applications, one thing is absolutely certain: power LEDs are here to stay.