Jianzhong Jiao: In general, there are differences between OEMs across the world. My observation is that for Japanese manufacturers, the emphasis is on potential savings in power consumption, which translates into lower fuel consumption. These have been calculated by studies at government level and are significant enough for companies to pay higher initial costs for LEDs, with the goal of longer-term savings.

What about US manufacturers?

JJ: I think that in the US the driving force has been styling. Studies have shown that if all bulbs on all vehicles in the US were converted to LEDs using today's technology, this would save roughly one billion gallons of gasoline per year, equivalent to the amount imported by the US every five days. This may be significant but very often, even if power is saved on lighting, the vehicle manufacturer will use that power somewhere else on the vehicle.

What aspects of styling benefit from the use of LEDs?

JJ: There are certain configurations of lamps that cannot be achieved easily using conventional bulbs. LEDs proved to be ideal for center high-mounted stop lamps (CHMSLs), which are often designed to be very thin. As the performance capabilities of LEDs improved, more options opened up for designers to introduce different shapes and lit appearances and to create attractive and differentiating features on the vehicle. The latest approach is to use signature lighting, meaning that lamps with a specific shape and appearance are used to distinguish the brand of the vehicle.

JJ: Essentially, the reason is cost, even though there may be advantages in terms of power consumption or size. LEDs may help to some degree to promote vehicles, but do people really buy vehicles because they have LED rear lamps? I don't know if the car makers really believe that. For the last few years, LED technology has been capable of providing stop-turn-tail lamps, but only a very few vehicles have implemented such lamps. These tend to be high end vehicles such as Cadillacs. By contrast, my company's experience is that most new vehicles tend to use LEDs for CHMSLs. Again, the only reason not to use LEDs in CHMSLs is cost.

What else do LED suppliers need to improve, in addition to reducing cost?

JJ: Vehicle OEMs have concerns, which I think are valid, about LED lamp lifetimes. Although LED makers can claim super-long lifetimes for individual components, for vehicle lighting you have to integrate the LEDs with circuit boards and other control devices so that the whole electronic system will have a long life.

It's possible to see older cars with CHMSLs containing lots of LEDs and several circuit boards in which some of the LEDs do not light up. The LED chip may still be OK, but the lamp does not work. The vehicle OEMs strongly urge that LED makers work with lighting manufacturers and sub-system integrators such as circuit board people, to ensure the lamp as a whole has long life.

JJ: If it is possible to increase the luminous flux of a single LED chip to a level close to that of an incandescent source, we feel there will be a huge cost reduction compared with using multiple LEDs, which tend to require complex and specialized circuit boards. But of course single-LED solutions don't necessarily provide the same flexibility of styling; for example, they are not ideal for CHMSLs, or a rear lamp that has a high irregular, non-symmetrical shape ? very narrow, wrap-around the vehicle body, etc.

What are the challenges to be faced before LED headlamps are introduced?

JJ: Although white LEDs are likely to reach the required performance levels, integration of these LEDs is still a very complicated process, including optical, mechanical and electrical aspects. For early-stage adoption, perhaps in 2007, the projected cost will still be very high.

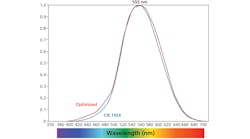

The performance is almost at the required levels. There are two main factors, one is the light output, meaning total lumens and luminance (brightness) per LED, the other is the size of the lamp. If you can accept a larger lamp size then the brightness per LED requirement can be lower. Traditionally, lamp size is dominated by styling. The result is that car makers are pushing for higher performance from smaller LED lamps. Beam shaping is not an issue provided you can get the desired performance from the LEDs.

What about competition from other technologies?

JJ: For red lamps, LED technology is state-of-the-art and only really competes with incandescents. LEDs are always more efficient, so the competition comes down to cost.

White LEDs in headlamps face a very strong competitor, namely high-intensity discharge (HID) lamps. HID lamps not only have very high performance but also have much lower power consumption, typically only 42 W per lamp. For LEDs to achieve this level of power consumption will require considerable improvements in system efficacy.

The good news is that, in the longer term, LEDs are expected to have much higher efficacy than at present. If LEDs can't match the efficiency and cost of HID at the lamp level, then the implementation of LEDs in headlamps will be very limited. In this case, only certain niche applications and special models will take advantage of the styling and other benefits.