One such technology is the Light Shaping Diffuser™ (LSD), developed and manufactured by Physical Optics Corporation. Existing LSD applications already include LCD backlights, LED displays and machine vision, as well as automotive and aerospace lighting. The technology is now finding volume applications within architectural and signage lighting.

Developed in the late 1980s and available in production since the early 1990s, LSDs have enabled lighting designers to solve problems of controlled light delivery in ways that had previously been impossible, or at least extremely expensive.

LSD technology

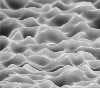

LSDs work as diffusers for any kind of light, independent of its wavelength or source. They also eliminate Moiré patterns and color diffraction, and provide dramatic results in terms of high transmission efficiency, virtually unlimited beam-shaping capability and the total homogenization of light.

When used as a diffuser, transmission efficiencies of up to 92% can be achieved, with excellent light uniformity. This compares with around 65% efficiency for ground glass or plastic diffusers. Under certain conditions LSD structures transmit more light than the original material from which they're made; for example, polycarbonate only transmits a maximum of 89% of light. This is because the holographically generated surface possesses special anti-reflective properties. As LSDs provide greater photon density, compared to other diffusers, they are highly suitable for high ambient light conditions.

Homogenisation

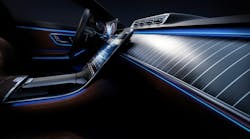

LSD films with wider diffusion angles make outstanding conventional diffusers and are already used extensively to disperse light evenly across the screens of lap-top computers, instrument panels and mobile phones.

With LEDs, the diffusing material can be placed almost on top of the LED - despite the LEDs' brightness and intense directionality, a totally uniform effect is achieved over the entire area, with no imaging (see Homogenisation photo).

Importantly, the diffusion effect of LSDs is based on diffraction, rather than refraction. Also, LSDs do not converge light, they control the light distribution by divergence, emulating a negative lens. Therefore they cannot make a spot of light smaller.

Shaping the beam

For example the "circle-to-rectangle" version of the film can re-shape an ordinary circular beam of light into a perfect rectangular distribution, which could have great potential for certain lighting applications using LEDs (provided that the source is highly collimated).

Another version, a "line generator" film, can take the same circular beam and stretch it in one direction only, throwing a long line of light on a wall or along the floor, much more effectively than the large pressed glass elongation lenses currently in use. Other applications could include using special elliptical LSDs in front of the lamp, so that circular beams always appear perfectly circular, even when projected onto walls at different angles.

The technology has great potential for lighting designers; for example, the film could be used to shape the distribution of road lanterns, to prevent unwanted back spill and "light trespass". LSDs can be effectively combined with other optical components such as lenses, Fresnels, and prismatic material - and in future luminaire design, the holographic structure could be replicated directly onto glass or injection-moulded into plastic parts.

In addition to its usual forms, namely as a thin web film and sheets in polycarbonate, polyester and acrylic, LSDs are available as cut-to-print parts, colour-tinted, as a double-sided diffuser, as UV-transmitting acrylic and in the form of a glass substrate for high temperature or high energy (laser) light sources.

About the author

Lis Eastham is a Sales Engineer and Product Specialist with BFi Optilas Ltd. Telephone: +44 (0)1908 326326.

BFi Optilas Ltd is the UK and European distributor for Physical Optics Corporation (POC), Torrance, California, which manufactures Light Shaping Diffusers.

BFi Optilas Ltd is a member of the Photonics Cluster (UK).