SCOTT ZIMMERMAN, WILLIAM LIVESAY, and WILLIAM EVANS describe the advantages of combining a modular approach to LED lighting with DC power distribution to simplify installation, increase efficiency, and deliver a custom look in the built environment.

While traditional LED-based products using AC/DC drivers are proving successful in the lighting market, a more efficient lighting method using DC modular lighting can prove more advantageous in many applications. This article will describe one approach to DC modular solid-state lighting (SSL) and demonstrate its advantage in efficiency along with ease of installation and integration directly into the built environment. Moreover, the concept could fundamentally change the perception of finished luminaires as the building block of commercial indoor lighting and deliver unprecedented advantages for the environment.

Interested in articles & announcements on DC power approaches to LED lighting?

DC modular lighting consists of multiple low-voltage DC zones, each containing multiple, modular, and movable SSL elements instead of singular large dedicated fixtures. By eliminating single-purpose fixtures and using low-voltage DC modules, the end user no longer needs to fear lighting and can more easily participate in its design, installation, and adaptation. There is a cascading set of benefits derived from eliminating dedicated fixtures and high-voltage AC for lighting.

LED efficiencies and technology have increased to the point that large AC-powered fixtures are no longer the best and most efficient lighting solution. Here we will consider a different kind of SSL source that combines the LEDs, interconnect, diffuser, light-emitting surface (LES), and heat sink into a single ceramic element. With the LES as the primary and only heat sink, the light source can be fixture free. Details of this Goldeneye Airelight module design were presented at LightFair International and covered in a recent article on the LEDs Magazine website.

This article will consider some case studies based on the aforementioned module and a DC modular lighting approach. Such modules are efficient both in terms of energy and materials. For example, the Airelight module can deliver over 1800 lm using less than 60g of material (30 lm/g). These light sources are only 1/4-in. thick, 1-in. wide and typically 2-ft long. Moreover, they can be safely embedded into any building material including ceilings and wood (Fig. 1).

FIG. 1. DC modular lighting can be surface mounted or recessed when used with most any common building material.

Modular advantages

A lighting system based on modules offers numerous advantages starting with flexibility. The lighting system can be easily repurposed or rearranged based on changing needs of the end user. This fixture-free lighting gives the end user the ability to customize and create lighting for their own needs, without the constraints of dedicated fixtures or common building materials. The flexibility applies both at initial installation and in so-called day-two changes to a lighting system.

The modules also offer logistics advantages. A 12,000-lm lighting system might weigh a total of less than two pounds and ship anywhere in the US via two-day air for under $14.00. Customers can buy modules in volume, taking advantage of standardization, yet utilize the modules in creative ways in different spaces within a facility - including in installations that mimic traditional fixtures where required. DC modular lighting components are ultimately less costly to manufacture, distribute, purchase, install, recycle, and adapt into different lighting applications.

Electrical and mechanical advantages

In addition, the DC modular approach provides benefits in terms of the electrical installation and power grid and the mechanical installation. Ultimately, worker safety is improved because Class 2, 24VDC power distribution is inherently safer than 120V or 277VAC power distribution. Moreover, modules that weight less than 10 lb in aggregate to illuminate a 7500-ft2 space are much easier to handle and install relative to SSL fixtures that might weight 500 lb in aggregate.

To summarize, consider these advantages of DC modular lighting:

• Flexibility to work with Class 2 DC wiring

• Ability to work either within or without the lighting fixture paradigm

• Ability to install in places that would be difficult for typical, higher-voltage AC-powered systems to be installed

• Potential to increase the level of standardization between differing applications due to the modular components

• Potential to simplify the installation of a lighting system

• Potential to reduce the AC-to-DC power losses attributable to conversion in each fixture of a lighting system

• Simplified dimming on the DC side of the power supply

• A natural fit for SSL since the majority of LED light engines available on the market today are natively powered by DC power

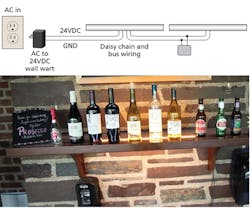

FIG. 2. Shelf-based or under-cabinet lighting is an example of DC-powered lighting that can be daisy chained or connected via a DC bus.

The DC modular approach can also be easily accomplished today. Moreover, the scheme can help bridge the gap between where we are today and where it would appear many believe we should move - to a complete DC power distribution throughout a building. Indeed, centralized conversion for efficiency, compatibility with renewable sources such as solar, and DC synergy with devices such as computers and servers would argue for a DC grid in buildings. LEDs Magazine has run several articles on DC grids, including a feature in 2014 that described a bank that used solar power and DC to power all office systems.

Contrasting legacy fixtures

Considering this discussion, how do legacy fixtures, including LED-based luminaires, compare? Historically, fixtures have been large, heavy, and designed for high lumen output with three major functions: protecting the user from AC voltages; protecting the building materials from the high-temperature light source or the power supply; and creating a particular light distribution. With low-voltage DC modular lighting, the first two of these functions are no longer relevant as we have discussed previously.

We will get to light distribution momentarily, but first understand why larger high-output fixtures have been a popular basis of lighting systems. In the past, concentrating lighting into fewer large fixtures made sense because of the cost of installation and the distribution channel to market. The cost of a typical installation was two to three times the cost of the fixture. Fewer fixtures meant fewer installations and lower costs.

Unfortunately, large fixtures are inherently inefficient when you want to distribute light evenly throughout a room. A downside with this approach is that it creates large variations in illumination levels throughout a room. DC modular lighting allows lighting designers/specifiers the ability to distribute sources uniformly in a space with inherently more uniform light levels.

Market obstacles

Unfortunately, it is quite difficult to change a major infrastructure that has been around as long as fixture-based lighting. The US Department of Energy (DOE) and market-transformation programs such as Energy Star, recognizing that it would be difficult to completely change this infrastructure, pushed SSL programs that emulated the look and feel of traditional fixture lighting or were plug-and-play compatible with traditional lighting. The problem with taking that approach is that it handicaps truly innovative approaches that would offer even more efficiency and flexibility.

Consider a case in point being California's rebate program, which rewards $100 per fixture to customers and/or companies that replace fluorescent troffers with lookalike SSL troffers. But since DC modular lighting does not look like a fluorescent troffer, it is not eligible for the $100 rebate. More innovative approaches therefore are penalized when regulations or bureaucrats attempt to pick winners.

FIG. 3. A multizone system driven from a single power supply can have multiple dimmers that control the individual zones or different layers of lighting.

The underlying flaw in the government's replacement programs is that it is based on the false assumption that existing lighting designs are optimum when in fact more energy can be saved using distributed DC modular lighting than is saved in just converting to LEDs. These programs also fail to account for all the hidden costs and environmental impact associated with extra raw materials needed to make large, heavy fixtures, and their distribution, shipping, packaging, and safety costs.

The DC/LED marriage

Still, DC modular lighting is too significant to fail regardless of obstacles. It addresses the main tenets of sustainability: reduce, recycle, and reuse through designing lighting around the unique properties of LEDs. Consider some main attributes of LEDs and the disconnect with traditional lighting fixtures. LED lifetimes exceed remodel or repurposing times, but LED-based fixtures can't easily be reused whereas modules can. Absent AC power, LEDs require very little material per lumen - output can be greater than 20 lm/g. As mentioned earlier, LEDs are inherently low-voltage DC devices as are most other electrical devices today, even including consumer devices such as cell phones, TVs, and household appliances.

Indeed, we are surrounded by devices that prefer to run off of DC, not AC. The problem is almost all buildings, homes, etc. are wired for AC. But now, what if all the lighting were DC? Would we adapt in other areas? Lighting is required in every occupied space, even your attic. Could lighting facilitate a migration from AC to DC? Historically, AC and all its associated costs and safety issues were required in lighting because each fixture consumed 100-1000W of power. Now most fixtures consume 10-50W of power. This is a classic disruptive event in which the previous technology and market drivers are no longer valid.

DC modular case studies

Now let's move to the case studies. The simplest DC modular lighting system has been around for years in kitchens - low-voltage, under-cabinet countertop lighting. These systems tended to be based on puck lights, which created a series of hot spots where they were mounted. These early DC sources suffered in efficiency, size, and lumen output. In contrast, the linear SSL modules discussed earlier output at least 500-1500 lm from a single element in a uniform manner and from a very thin design.

Fig. 2 depicts how DC-powered linear modules might be deployed in an under-counter or shelf application. A DC power supply or wall wart supplies a constant voltage output. The example includes two linear modules that are daisy chained to the supply, although the implementation actually connects the modules in parallel in most cases - the daisy chain passes through the DC input.

The modules are designed such that the 24V output of the power supply is just sufficient to match the forward voltage of the series string of LEDs in the module. The low voltage makes sure that the LEDs operate very low on the LED device IV (current/voltage) curve for optimum efficiency. The diagram also shows that a DC bus could connect multiple sets of modules. A pulsewidth modulation (PWM) dimmer placed between the supply and the modules would enable dimming functionality.

The higher lumen output available in linear modules transforms traditional under-cabinet task lighting. For example, in the Airelight case, two 24-in. strips can deliver 750 lm/ft and at 1/4-in. thick could be surface mounted or recessed into wood. The Princeton University wood shop created an inlaid installation to prove the concept. And the ability of the scheme to use locally-sourced mounts enables both a higher degree of customization and freedom from shipping materials for mounting.

Multizone systems

Now let's consider a more complex SSL system. Princeton University used modules to create a custom lighting system in an office that included ceiling-mounted wall wash lighting, indirect ceiling lighting, inlaid task lighting mounted on shelves, and pendant lighting. The entire system is powered via a single 24VDC supply or constant-voltage LED driver.

Fig. 3 shows schematically how the system was connected. An LED driver essentially connects all of the linear modules in parallel. But the system breaks the modules into zones with an Illumra dimmer dedicated to each zone. The Illumra dimmer switches use energy-harvesting technology rather than batteries such that a person depressing the switch generates sufficient energy for the switch to send a wireless command to the dimmer. The products are based on the EnOcean Alliance wireless standard. Although the diagram shows two zones, the actual Princeton case study includes four zones.

In a new installation, you could install low-cost wiring to carry the DC power. In the Princeton case, the existing AC wiring in the building was converted to carry DC, eliminating new wire routing and enabling copper reuse.

Complex retail systems

Upping the complexity, a high-end AV store called Bravo in Bernardsville, NJ installed a DC-based system throughout the store using modules (Fig. 4). The eight-zone system could again use a single driver so long as the specified driver can deliver the current required for all of the modules. The eight zones include custom linear lights embedded in the ceiling, merchandise platforms, and walls, providing not only lighting but also highlighting speakers hidden in the acoustical wall panels. The system also provides front-window lighting, under-counter lighting, and suspended-ceiling lighting for storage, bathrooms, and work areas.

The eight-zone implementation relies on a more robust wireless control system designed for more dense lighting applications. Each of the eight zones was equipped with a Lutron LMJ RF dimming module that works with the Lutron RadioRa wireless network. The LMJ modules output a 0-10V dimming signal to Illumra dimmers that in turn convert the dimming control to PWM of the DC power in each zone. A variety of Lutron RadioRa controls could be used with such an installation.

By implementing the dimming function on the DC side of the system, the installation avoided any dimming issues with legacy AC dimming technologies such as phase-cut dimmers or triacs. Moreover, the scheme as implemented enabled dimming down to 1%. And the project demonstrated the flexibility of the DC scheme because the store was able to make changes and add new lighting modules to the system as the installation progressed.

Data center lighting

Depending on the power supply chosen, the DC modular system can be scaled to serve even far larger areas in commercial and industrial settings. One example is an IT data center located near Princeton. The linear modules were used to light a 3000-ft2 space in the data center - primarily the aisles between the server racks. The same modules were also used in hallways and offices.

FIG. 4. Retail implementations of DC modular lighting, as seen in this AV store, can extend to more zones and use wireless networks proven in complex environments.

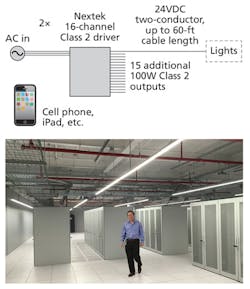

FIG. 5. In a data center, linear modules are powered by a multichannel driver and attached magnetically to ceiling beams.

Fig. 5 depicts the basic schematic of the system that in this case utilizes a multichannel constant-voltage power supply from Nextek. Nextek specializes in multichannel power systems and has been a leading proponent of the eMerge Alliance DC grid system that is targeted at DC power for both lighting and IT systems. The Nextek supply in this instance was designed for eMerge systems but can be easily used in any system that needs 24V, 100W channels.

The data center installed 20-ft continuous runs of the linear modules in the sever rack area. The installation illustrates the mechanical flexibility as the modules were magnetically attached to uni-strut beams that were suspended from the ceiling. In the office and hallways, the modules were magnetically attached to the T-grid ceiling. Low-cost two-conductor wiring was run to the modules.

Project cost

Throughout the case studies here, the DC approach to lighting delivered cost savings both in terms of energy and total cost of ownership (TCO). TCO includes installation, distribution, shipping, wiring, recycling, raw material utilization, safety, and other lifecycle costs. While the SSL industry has focused on lumens per watt or efficacy, the opportunity now exists for the industry to take a broader view.

The question still may be asked, why move to DC? The pragmatic answer will be to save money. But DC is destined to be the wave of the future for other reasons and DC modular lighting can be the transition vehicle. Moreover, such an approach delivers another tangible reason in terms of environmental impact that extends beyond energy savings.

SSL retrofits and the environment

Despite energy efficiency, the SSL transition is still adversely impacting the environment. Fifty billion pounds of lighting fixtures in North American ceilings are being replaced with fifty billion pounds of SSL fixtures unnecessarily.

FIG. 6. DC modular lighting is far more efficient in terms of materials required relative to legacy fluorescent lighting or even fixture-based LED lighting.

Compare the materials needed to light a space. Twelve of the linear modules, a single driver, and some basic wiring can deliver 12,000 lm from 100W (Fig. 6). Here we will provide a comparison with a fluorescent system. Such a fluorescent system would include the metal and plastics needed for three fixtures, along with the ballasts, and six tubes and more complex wiring, yet would yield only 6000 lm at 200W. An SSL fixture-based approach would balance the efficacy mismatch but still involve far more materials than does the modular approach.

Furthermore, there remains significant fire danger with the legacy fixture-based approach. Lighting may soon represent the single largest fuel source in ceilings during a fire. UL/NIST burn tests have shown an 8× reduction in the available escape time from a fire over the last several decades due in large part to increased plastics in our homes and workplaces. Also, no standards exist to quantify the toxicity of smoke generated during a fire. Unfortunately, the lessons learned by the telecom industry regarding fuel load and toxicity are being largely ignored by the lighting industry. DC modular lighting, as described herein, enables a lighting system that uses 1/10 the materials of conventional fixture-based lighting. Moreover, these lights don't burn in a fire, are 100% recyclable, and contain no hazardous materials.

Remaining roadblocks

Despite the advantages of the modular approach, however, obstacles remain. Chiefly market-transformation programs such as the DesignLights Consortium (DLC), and in other cases, government regulatory programs, are the culprits.

The DLC, for example, is hindering innovation by mandating only certain categories and performance standards that are tied to traditional fixture approaches in terms of products that will be eligible for subsidy. Not only can energy be saved using more innovative lighting designs but over 40 billion pounds of raw materials can be saved in North America alone through a new approach.

Final thoughts

Any holistic approach to lighting should focus on all the tenets of sustainability - reduce, recycle, reuse - not just on energy consumption. DC modular lighting can address all three of these tenets by reducing raw materials, being fully recyclable, and inherently being reusable or "repurposeable" as the needs in a space change.

DC modular lighting combines the safety, ease of installation, and cost savings of DC grids with sustainable light elements that replace fixtures. Such systems are inherently simple to install and use.

It is reasonable to assume that if Edison had LEDs available to him, he would have designed a light source that had two basic characteristics. It would have used DC and it would have used the minimal amount of materials. Even today the incandescent bulb emits 30 lm/g while a typical conventional LED fixture emits only 1 lm/g. The DC modular lighting used in these case studies achieves up to 50 lm/g. Edison would have liked DC modular lighting.

SCOTT ZIMMERMAN is vice president of technology and WILLIAM LIVESAY is CEO of Goldeneye. WILLIAM EVANS is an electrical engineer working in the Engineering and Campus Energy department at Princeton University.