Hamburg. ALBIS PLASTIC GmbH presents its line of plastic compounds for the solid-state lighting (SSL) industry at the Light+Building 2016 in Frankfurt am Main.

From March 13th to 17th ALBIS, located in Hall 4.0, Booth D61, will present its own brand ALCOM® LB (Light Blocking), ALCOM® LD (Light Diffusion), ALCOM® LG (Light Guiding) and ALCOM® TC (Thermally Conductive) as well as TEDUR® plastics for SSL design.

With these products ALBIS offers interesting and custom-tailored solutions for LED lighting applications and economically efficient alternatives for plastic components. For example the products from the ALCOM® LB (Light Blocking) line ensure high light blocking properties while simultaneously providing a high degree of reflection to increase light output. ALCOM® LB PC 1000 14073 WT 1164-14, a highly reflective polycarbonate with a reflection rate of 95%, is not only perfect for PVD coated parts; its excellent flow properties and surface quality also make it particularly suitable for production of uncoated, thin-wall reflectors.

Moreover the ALCOM® LB line of products represents the ideal housing material for safety lights and emergency lighting systems due to their high flame retardancy and glow wire resistance.

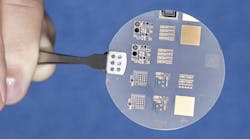

ALCOM® TC (Thermally Conductive) has an improved thermal conductivity to increase the efficiency of LEDs thus contributing to an increase in the service life of electronic components in SSL design. With ALCOM® TCE-PC ALBIS has developed a thermally conductive polycarbonate for co-extrusion with transparent or light diffusing PC and a thermal conductivity, which is up to eight times higher than the one of PC, for improved thermal management of linear LED lighting applications. This special compound offers good adhesion to polycarbonate for cost-efficient production of co-extruded profiles.

Use of ALCOM® LD (Light Diffusion) products ensures homogeneous and efficient light distribution by avoiding annoying hot spots. Moreover the ALCOM® LD line also offers ALCOM® LDX versions, light diffusing compounds for extrusion of profiles for linear LED light strips and covers. The ALBIS ALCOM® LDX line offers ready-to-use compounds with high translucence and optimum light scattering for homogeneous illumination.

"In addition to our plastic compounds, we also offer our customers light-scattering master batches for polycarbonate. These ALPERFORM® PC-LD and ALPERFORM® PC-LDX concentrates are used for injection molding and extrusion processes. In addition to cost efficiency, the advantages include high flexibility for individual adjustment of the light transmission and light scattering directly during processing", explained Joachim Bernhard, Director Marketing Electrical & Electronics at ALBIS PLASTIC.

Contact:

Jochen Vennemann - ALBIS PLASTIC GmbH+49-(0)40/78105-523

E-mail:

[email protected]Web site:

www.albis.comLocate more packaging & optics vendors in the LEDs Magazine Suppliers Directory

Submit new products, case studies/projects, and other press releases at http://www.ledsmagazine.com/content/leds/en/addcontent.html.

More from ALBIS Plastic:

Stefan Reiner becomes managing director of ALBIS Plastic Vertriebsgesellschaft mbH

Röber Kunststoffe expands LED lighting materials line with Albis Plastics' ALCOM LDM polycarbonate