West Conshohocken, Pa. – Heraeus Precious Metals, a world leader in industrial precious specialty metals and technology, announced that its Celcion® material system – including a dielectric, conductor, and solder mask – has been certified and received recognition status by Underwriter Laboratories (UL®), a global, independent, and non-profit product safety testing and certification organization.

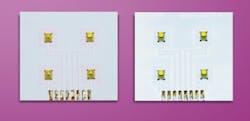

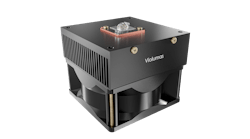

“UL®’s recognition gives customers the assurance that our Celcion® material system meets the stringent safety and performance requirements of thermal circuit technology”, said Mark Challingsworth, Technology Director, within Heraeus Precious Metals’ Electronics Materials Division - Business Unit Circuits & Components. “Passing the certification test and meeting UL’s industry standard for flammability testing is the ultimate seal of approval. Knowing that the system has passed UL’s stringent testing; our customers can feel confident using the Celcion® system in their LED thermal substrate applications.” As a result of the successful completion of testing by UL®, Heraeus Celcion® has proven reliable, safe and as a highly effective alternative to traditional metal core printed circuit board (MCPCB) manufacturing. Heraeus Celcion® passed some of the most rigorous tests in the industry to gain UL®’s recognitions, including: • Recognition of Materials for use in fabricating UL recognized printed wiring boards • Recognition for Solder Resist for physical, electrical, flammability, thermal, and other properties of the materials Heraeus Celcion® is a thick film material system that was designed to produce electronic circuits for LED lighting on aluminum (Al) substrates. Celcion® is able to take the same fit, form and function as MCPCBs, but delivers an increased thermal conductivity and high-dielectric breakdown strength. This process incorporates a selective additive deposition that uses material only where it is needed, which results in less material consumption. By using a limited amount of material and removing interface materials, this reduces the thermal resistance and provides a more direct connection to the Al heat sink. Celcion® circuits typically run 10°C or more cooler than MCPCBs, which allows designers an increase in lumen power output and – thereby – reduces the number of LEDs needed by up to 20 percent. This solution decreases production costs and enables customers to add another material choice for high-power applications to their design kit, without sacrificing performance. The Celcion® material system is ideal for use in high-power applications – including high-power LED substrates (>1W input) found in general illumination, signs, signals, and displays – with distinguished performance benefits in power electronics and heaters. With the UL®’s certification and recognition, the Heraeus Celcion® material system has proven reliable and satisfies customer and industry standards. The Hanau-based precious metal and technology group Heraeus is a globally active family-run enterprise with a history of more than 160 years. We provide high-end solutions to our customers to lastingly strengthen their competitive position. Our areas of competence include precious metals, materials and technologies, sensors, biomaterials and medical devices, quartz glass and specialty light sources. In the financial year 2013, Heraeus achieved a revenue from the sale of products of €3.6 bn, while the revenue from precious metal trading was €13.5 bn. With about 12,500 employees in more than 110 companies world-wide, Heraeus is in a leading position on its global sales markets.Contact:

E-mail:

Web site:

Contact:

Yin Yin, Marketing Specialist - Heraeus Precious Metals North America Conshohocken LLC

+1-610-825-6050 Ext. 246

E-mail:

Web site:

www.heraeus.com

Submit new products, case studies/projects, and other press releases at http://www.ledsmagazine.com/content/leds/en/addcontent.html and http://www.ledsmagazine.com/content/leds/en/iif/add.html.