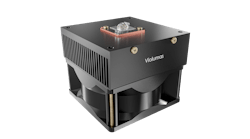

Heat pipe riveting and massive fins cooling technology

By using the Ø6mm heat pipe, the heat generated by the lighting quickly transfers to the cooling module of massive radiation fins, efficiently reduce the temperature of the LED lighting chips and extend the lifespan of the lighting source.

- 3-D heat dissipation

Professional heat dissipation structure design. Modular heat sink with perfect structure and inside airflow channels maximize the 3D heat dissipation.

- Compressed Fins Technology

GEB’s creative Compressed Fins Technology: rivet the heat pipe to heat sink body closely, minimize the heat resistance, greatly improve the heat dissipation effect, and it is much lighter compared with similar products.

- Patented HDT technology

High efficiency heat pipes contact the heat source directly, maximizing the performance of the heat pipe to achieve the cooling effect.

- Optional beam angle reflector

Flake designed high-purity aluminum reflector angle scales with PC cover options to meet professional light distribution needs, to adapt to different situations. There are 60°, 90°, 110° beam angle options for the flake designed reflector. And there are also two options for the reflector material, high-purity aluminum. The reflector is suitable for different situations.

- Built-in power driver design

Separate build-out power driver design is good at thermal dissipation, which improves the efficiency, stability and longevity of the driver.

Contact:

GeBright Optoelectronic Tech Co., Ltd. - DebbieSkype: debbie.geb

E-mail:

[email protected]Web site:

www.gebright.comSubmit new products, case studies/projects, and other press releases at http://www.ledsmagazine.com/content/leds/en/addcontent.html and http://www.ledsmagazine.com/content/leds/en/iif/add.html.